Anti-tilting cleaning-free comb plate telescopic device

A telescoping device and comb-tooth plate technology, which is applied to bridge parts, bridges, buildings, etc., can solve problems such as increased noise, tooth plates that cannot be restored, and hazards to driving safety, and achieve the effect of reducing gaps and avoiding the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

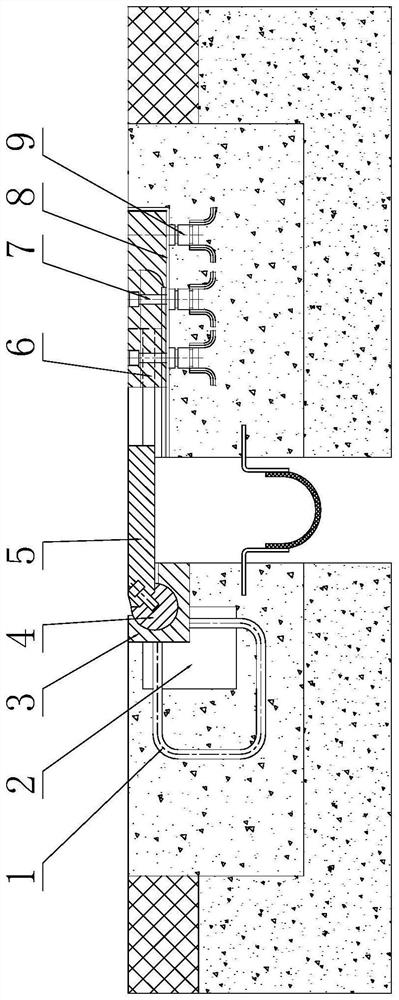

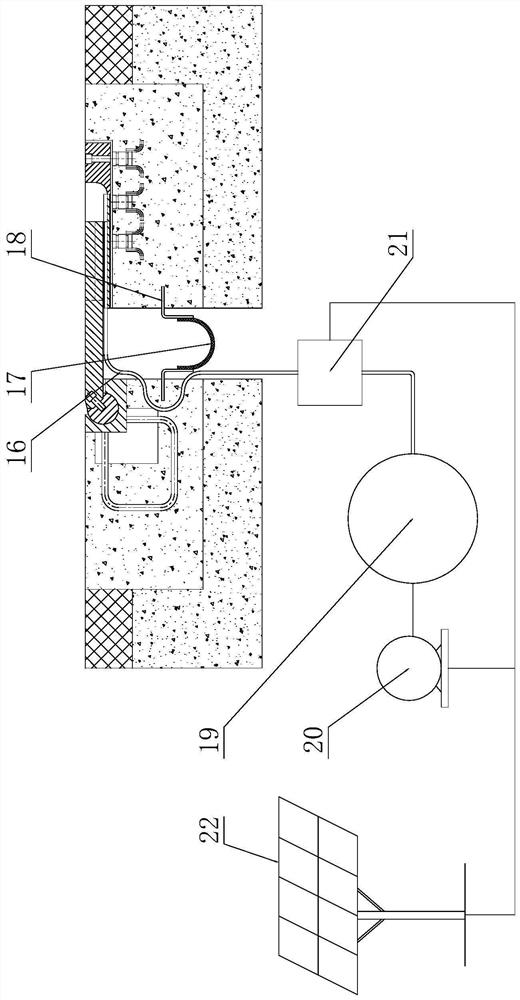

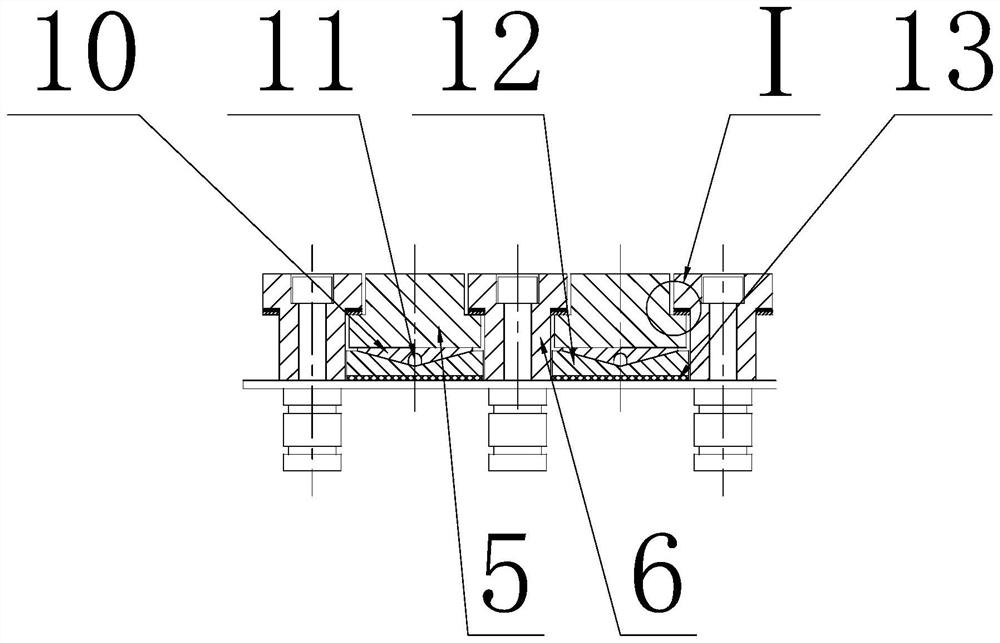

[0040] The overall structure of this embodiment is as shown in the figure, which includes a movable comb plate 5 whose root is connected to the beam end or abutment on one side of the expansion joint and whose front part overlaps the expansion joint, and its comb teeth are opposite to and fixed on the expansion joint. On the other side beam end or the fixed comb plate 6 of the bridge abutment, there is a fixed comb plate backing plate 8 under the overlapping part of the movable comb plate 5 and the fixed comb plate 6, and a rubber waterstop 17 is installed in the expansion joint ; The beam end or abutment located on the side of the root of the movable comb plate 5 is provided with a rotating sleeve 3 coaxial with the expansion joint, and the rotating sleeve 3 is fitted with a rotating shaft 4, and the root of the movable comb plate 5 is connected to the rotating shaft 4. It is fixed and can rotate along the rotating sleeve 3. There is a corner gap between the lower surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com