Construction machine

A construction machinery and wall technology, which is applied in the field of construction machinery, can solve the problems of cab rigidity drop, failure to consider fracture, etc., and achieve the effect of suppressing rigidity drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach ]

[0031] figure 1 It is a side view showing the hydraulic excavator 10 according to the first embodiment of the present invention. Hydraulic excavator 10 is an example of a construction machine. like figure 1 As shown, a hydraulic excavator 10 includes an undercarriage 11 , an upper revolving unit 12 rotatably supported by the undercarriage 11 , a working device 13 , and a plurality of hydraulic actuators.

[0032] The upper slewing body 12 includes an upper frame 20 rotatably supported by the lower traveling body 11 , a cab 30 supported by the upper frame 20 , and a counterweight 29 disposed behind the cab 30 .

[0033] The working device 13 includes a boom 14 supported up and down by the upper frame 20 , an arm 15 swingably supported by the distal end of the arm 14 , and a bucket 16 swingably supported by the distal end of the arm 15 .

[0034] The plurality of hydraulic actuators include: the boom cylinder 17, which operates to receive the supply of hydraulic oil from a hy...

no. 2 Embodiment approach ]

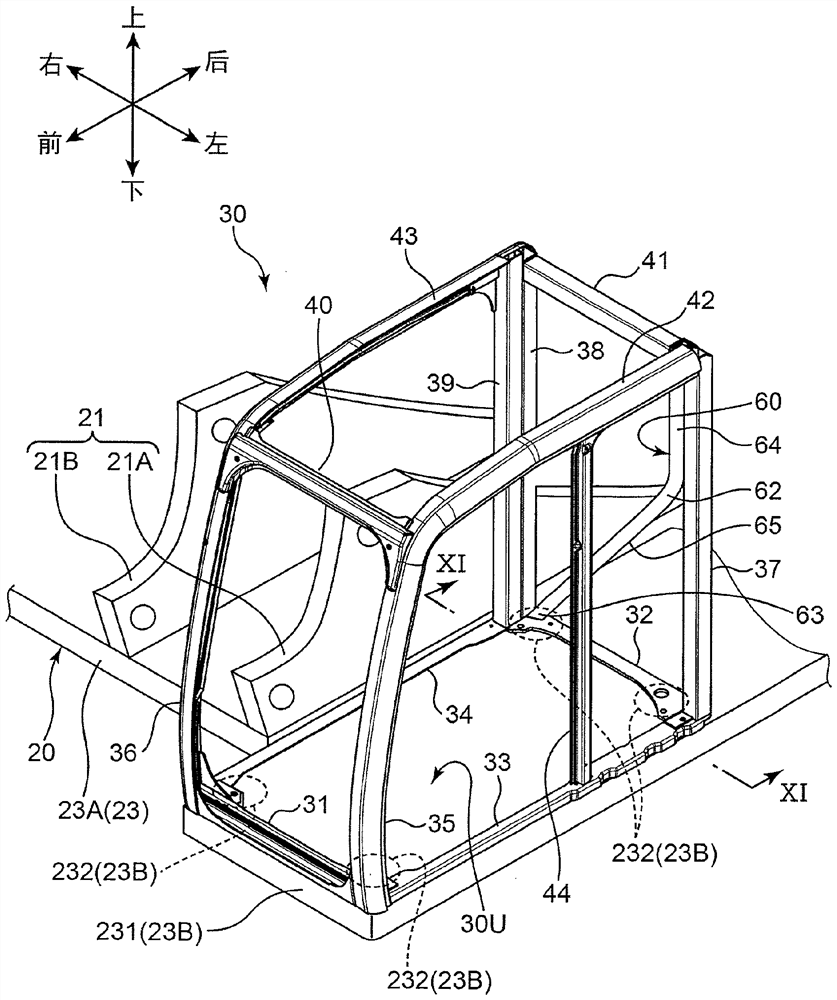

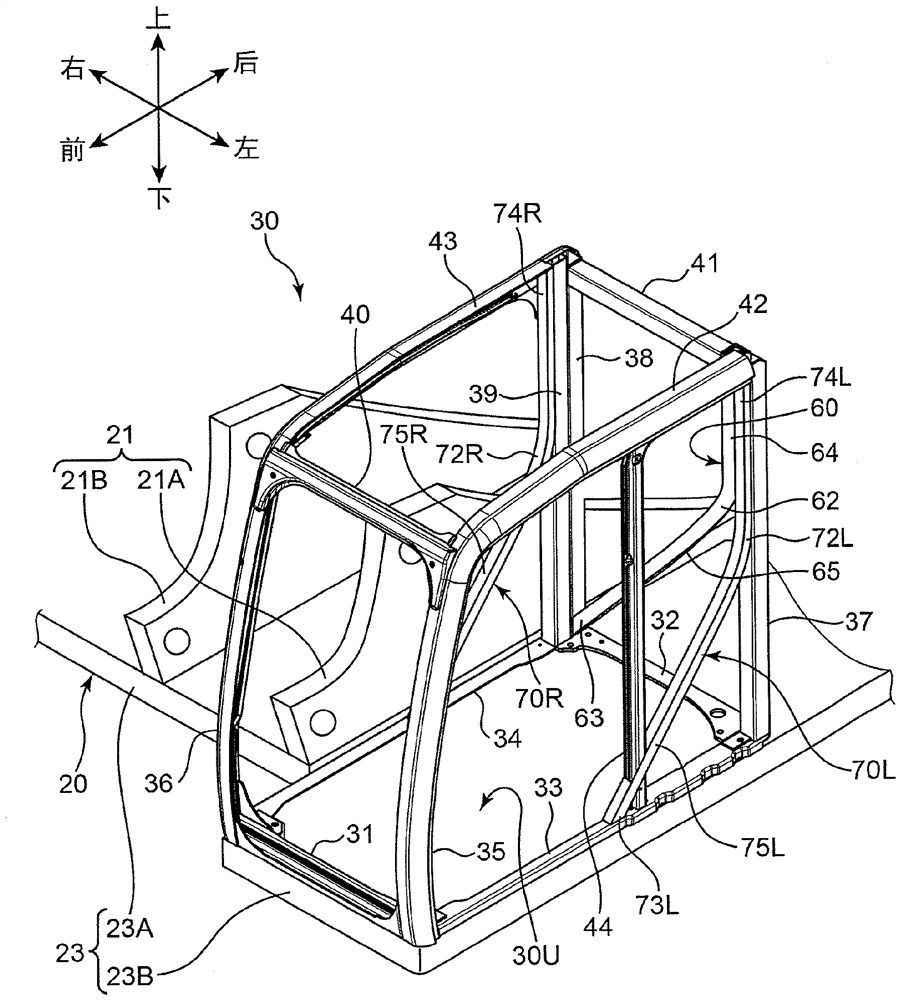

[0098] Figure 17 It is a perspective view showing part of a cab 30 and an upper frame 20 of a hydraulic excavator 10 according to the second embodiment. Figure 18 It is a side view showing the right wall portion 30R of the cab 30 and the load transmission member 70R. Figure 19 is a perspective view showing the left wall portion 30L of the cab 30 and the load transmission member 70L, Figure 20 It is a side view showing the left wall portion 30L and the load transmission member 70L.

[0099] The hydraulic excavator 10 according to the second embodiment is different from the fact that the cab 30 includes the load transmission members 70R and 70L. Figure 1 to Figure 6The hydraulic excavator 10 according to the first embodiment shown is different. Other configurations and Figure 1 to Figure 6 The above-mentioned first embodiment shown is the same.

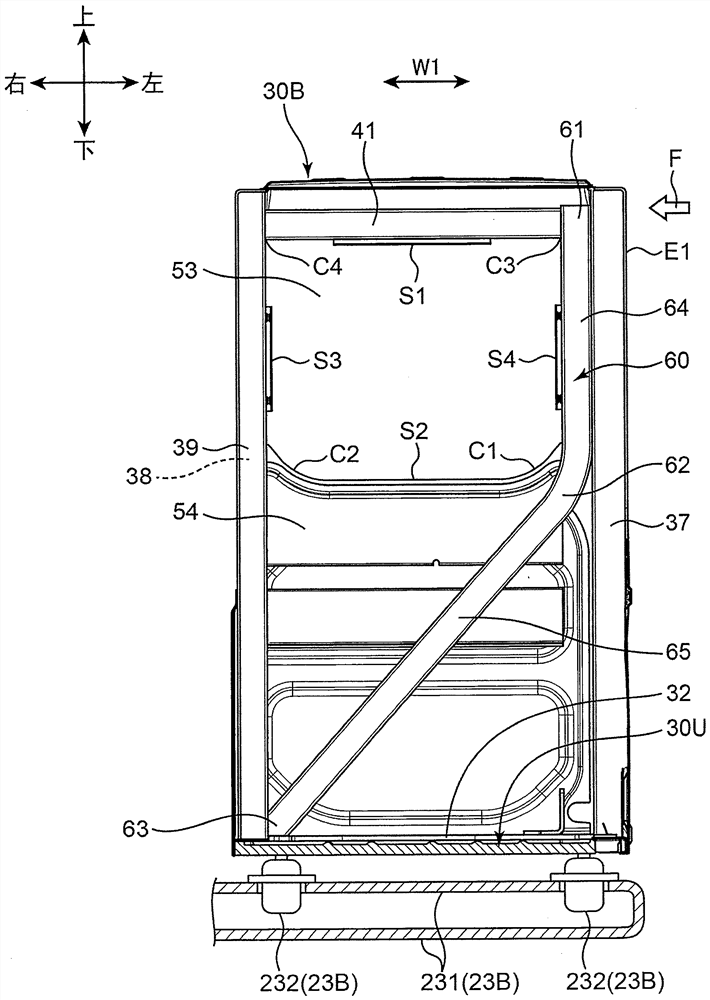

[0100] like Figure 18 As shown, the right wall portion 30R is located on the right side of the interior space, and is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com