Electric actuator

A technology of electric actuator and rotation sensor, which is applied to electric components, transmission boxes, electromechanical devices, etc., can solve the problems of increasing working hours and time, and achieve the effect of reducing working hours and time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

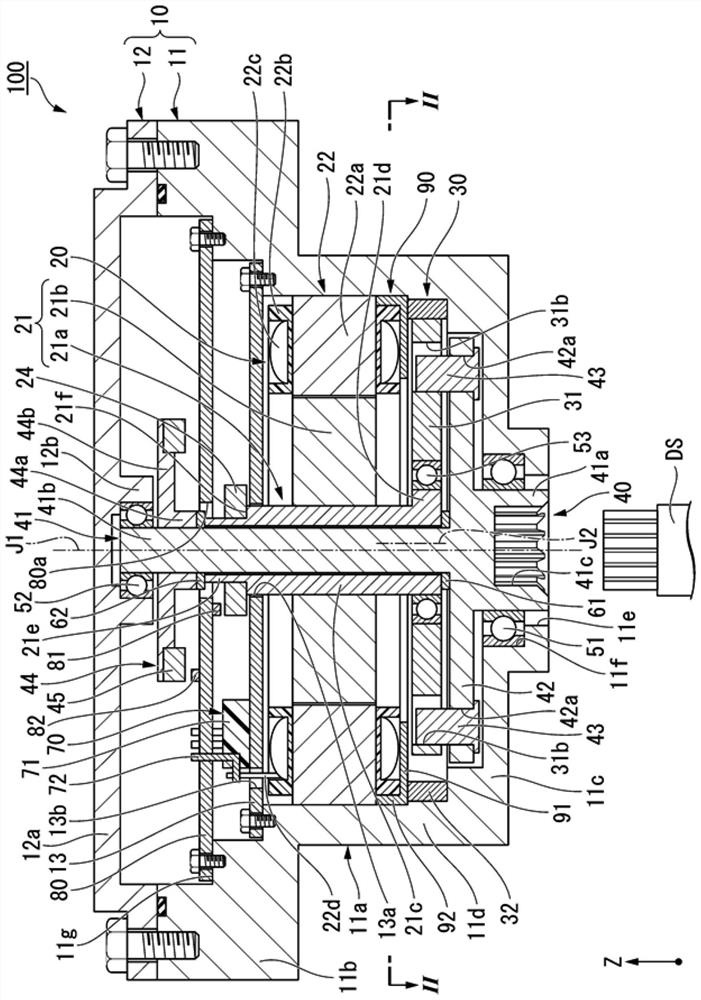

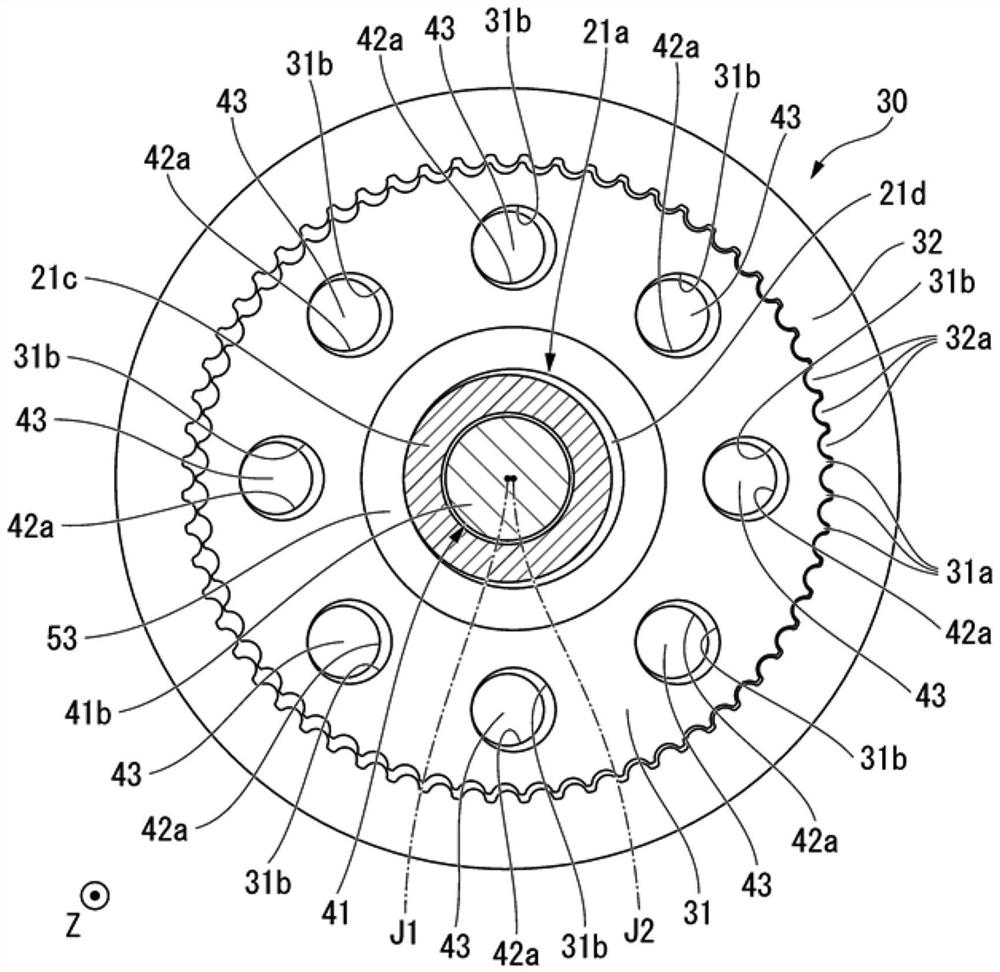

[0012] In each figure, the Z-axis direction is a vertical direction in which the positive side (+Z side) is the upper side and the negative side (−Z side) is the lower side. The axial direction of the motor axis J1 appropriately shown in each figure is parallel to the Z-axis direction, that is, the vertical direction. In the following description, the direction parallel to the axial direction of the motor axis J1 is simply referred to as "axial direction". In addition, the radial direction centered on the motor axis J1 is simply referred to as "radial direction", and the circumferential direction centered on the motor axis J1 is simply referred to as "circumferential direction".

[0013] In this embodiment, the lower side corresponds to "one side in the axial direction", and the upper side corresponds to "the other side in the axial direction". In addition, the up-down direction, upper side, and lower side are only names for describing the relative positional relationship of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com