Air source heat pump system, control method, computer device and storage medium

A technology of an air source heat pump and a control method, applied in the field of heat pumps, can solve the problem of high exhaust heat of the heat pump, and achieve the effects of a stable rising trend of exhaust temperature, ensuring good operation, and good exhaust temperature effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

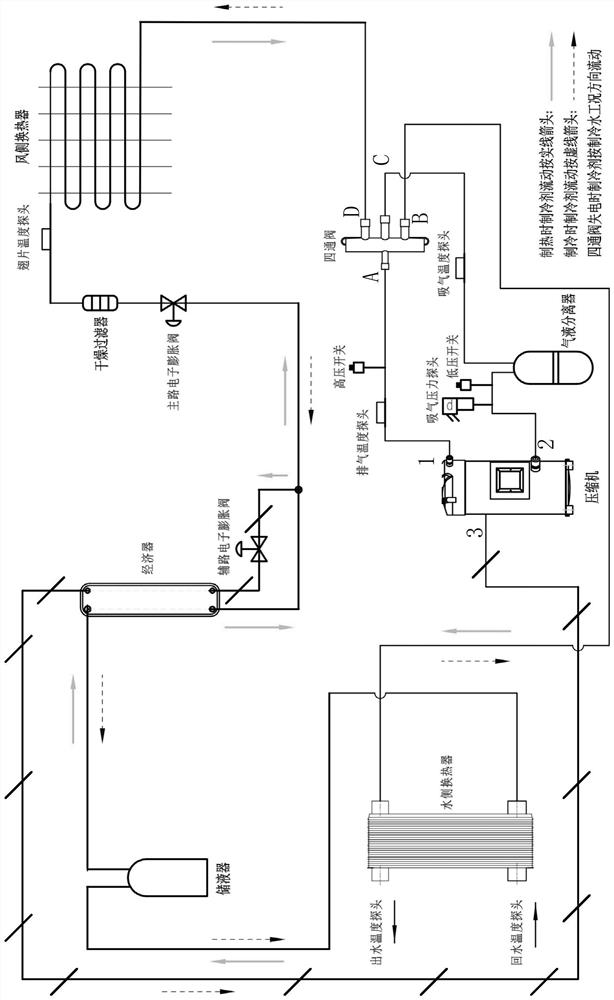

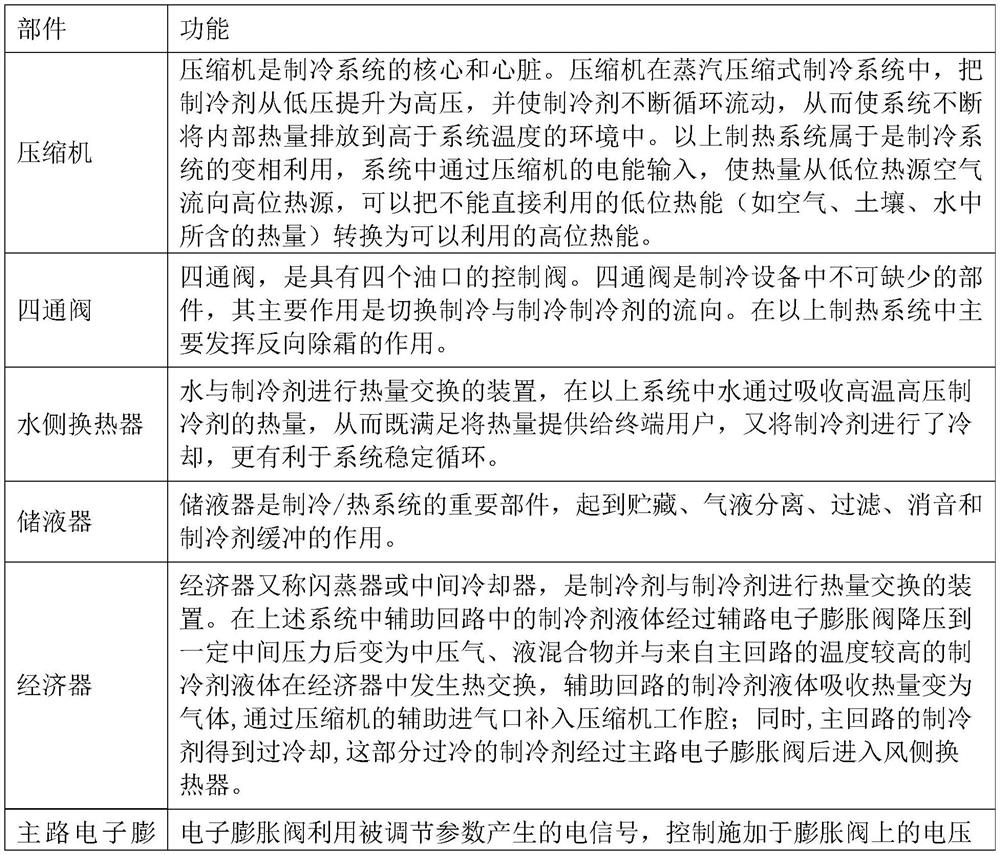

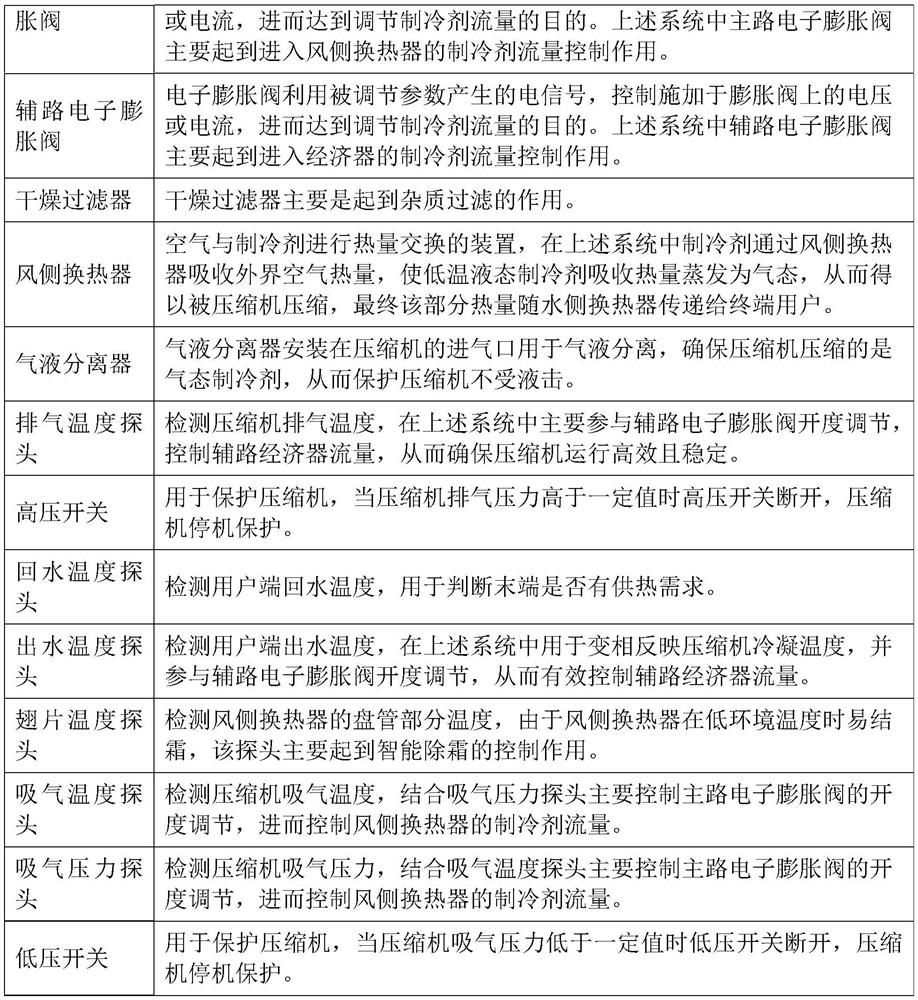

[0041] In this embodiment, the structure of the air source heat pump system is as follows figure 1 As shown, the air source heat pump system includes compressors, main loop pipelines, auxiliary loop pipelines, economizers and control modules, among which the compressors, main loop pipelines, auxiliary loop pipelines and economizers are all in figure 1 shown in, while the control module is not in the figure 1 As shown in , a single-chip microcomputer or a dedicated controller can be used as the control module, and the control module can obtain corresponding control functions through programming, and the control module can be controlled from figure 1 Sensors such as the exhaust temperature probe and suction temperature probe in the system collect data, run the control algorithm program to generate instructions, and thus control figure 1 The auxiliary circuit electronic expansion valve and the main circuit electronic expansion valve and other components.

[0042] refer to figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com