Cold storage heat recovery system

A technology of heat recovery and cold storage, which is applied in coolers, refrigerated rooms, household refrigeration devices, etc. It can solve the problems of unsatisfactory heat recovery efficiency, single structure of heat recovery cylinder, and inefficient water flow, etc., so as to improve heat recovery efficiency and accelerate Large contact, heat reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

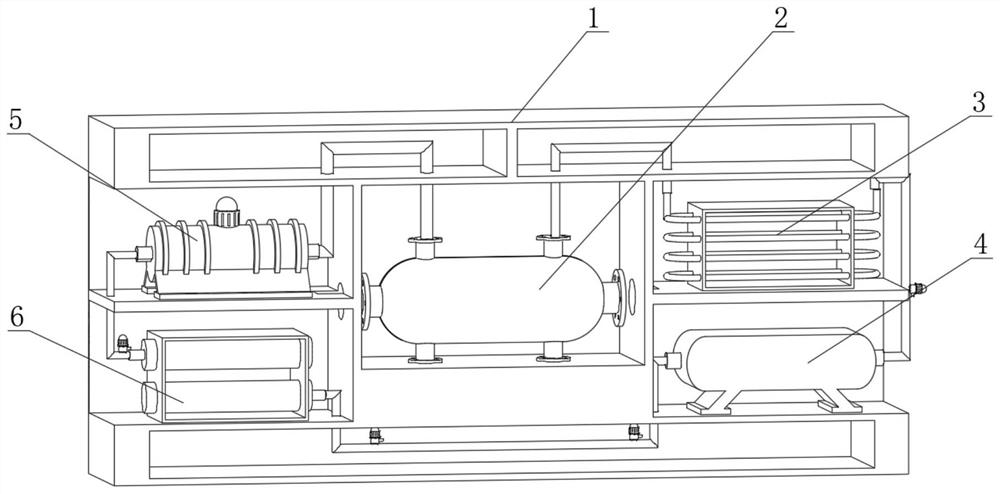

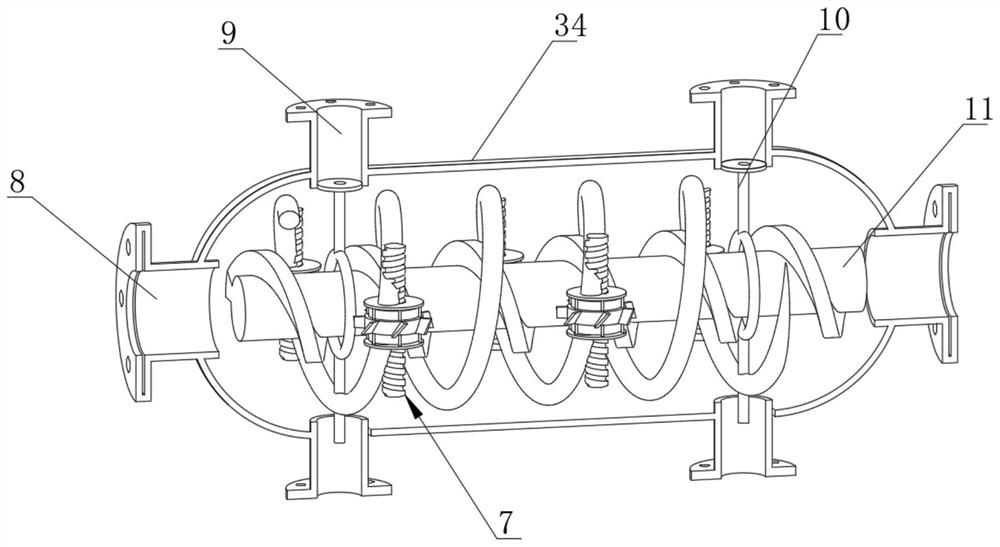

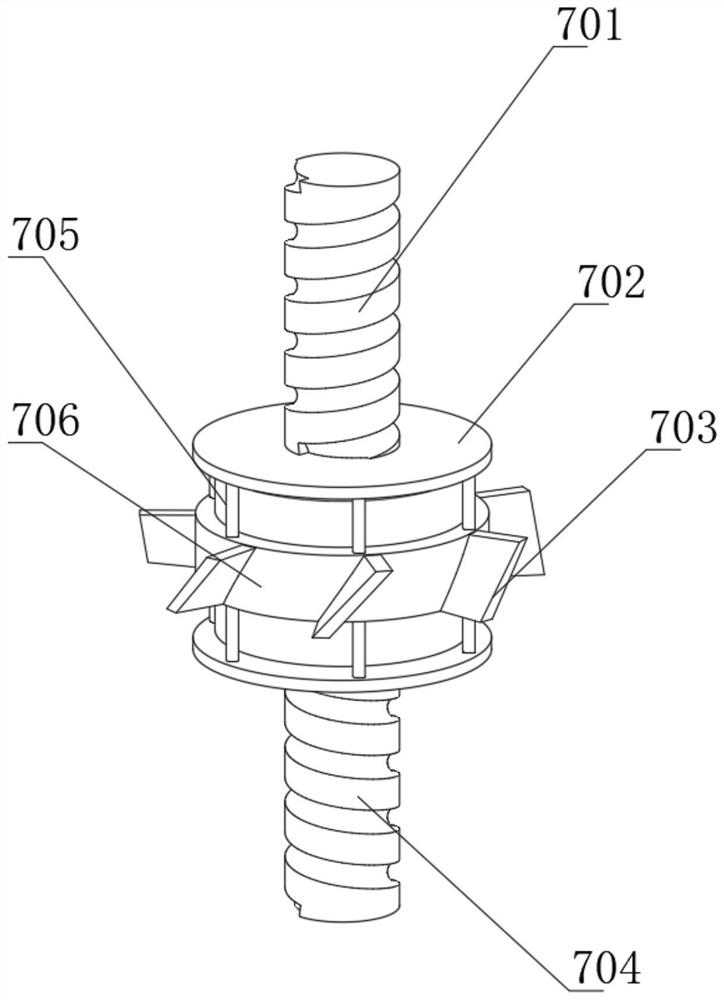

[0028] Such as Figure 1-7 As shown, a cold storage heat recovery system includes an installation frame 1, the upper side of the installation frame 1 is provided with a first upper pipe installation groove 17 and a second upper pipe installation groove 21, and the lower side of the installation frame 1 is provided with a lower pipe installation Groove 29, on the installation frame 1, also offer central working groove 19, the first working groove 22 of the right side, the second working groove 25 of the right side, the second working groove 30 of the left side and the first working groove 33 of the left side, the central working groove 19. The first working tank 22 on the right side, the second working tank 25 on the right side, the second working tank 30 on the left side and the first working tank 33 on the left side are fixedly installed with the heat recovery component 2, the condenser 3 and the liquid storage tank in sequence 4. The evaporator 6 and the compressor 5, the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com