Constant temperature type automatic reaction calorimeter

An automatic reaction and calorimeter technology, which is applied in the field of calorimeter and constant temperature automatic reaction calorimeter, can solve the problems of cumbersome cleaning of combustion residues and deviations, and achieve the goals of improving efficiency, shortening temperature difference, and improving flow activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

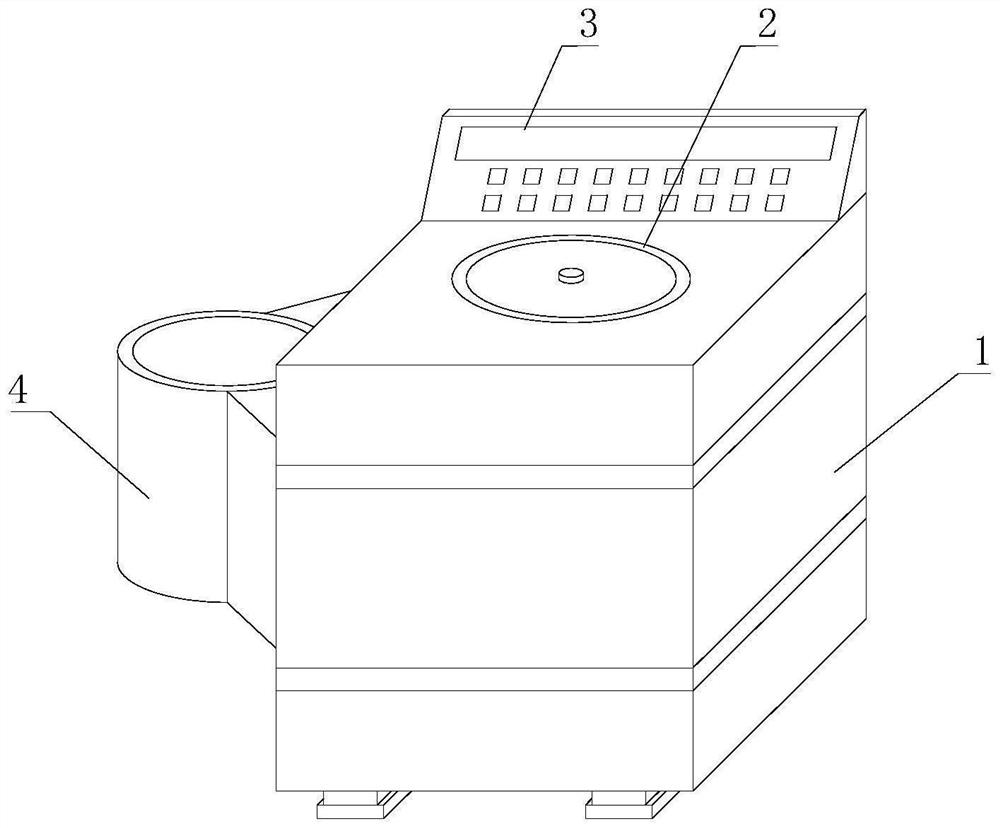

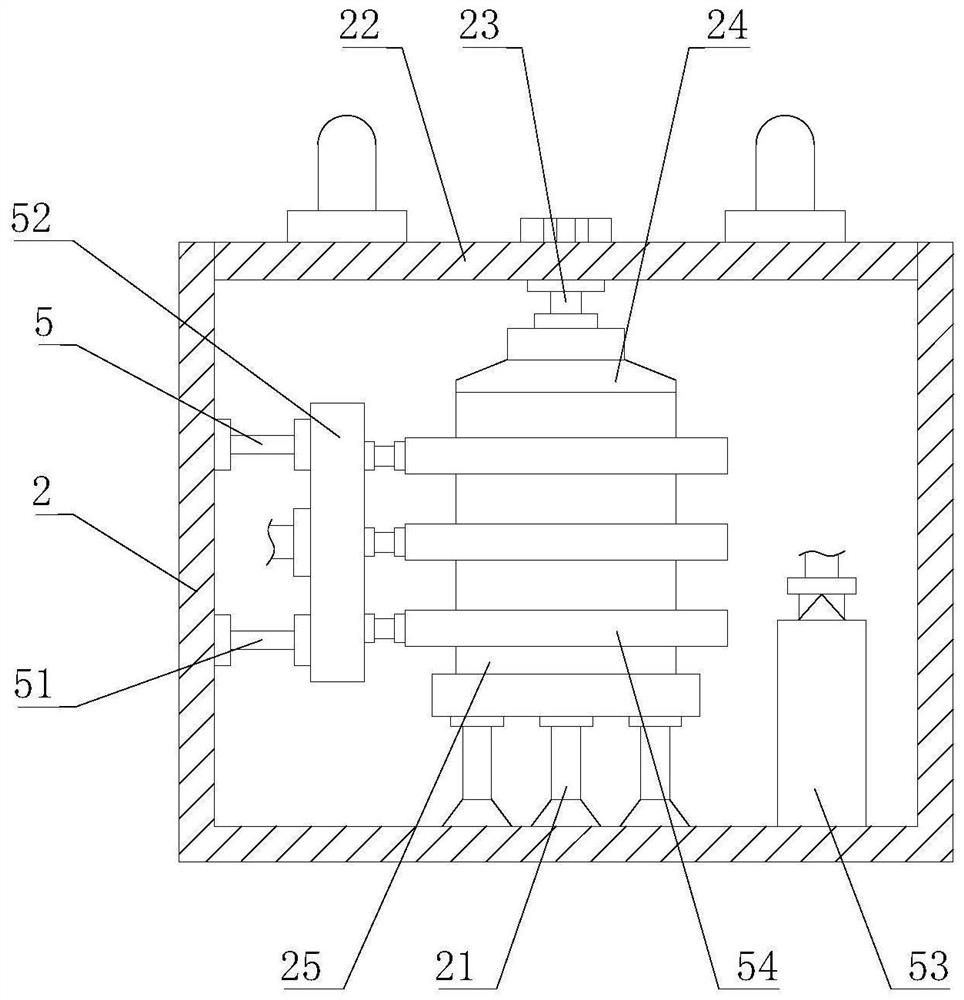

[0033] like Figure 1-7As shown, the present invention provides a constant temperature type automatic reaction calorimeter, comprising a constant temperature type calorimeter body 1, a calorimeter 2 is fixedly installed on the top of the constant temperature type calorimeter body 1, and a constant temperature type calorimeter body 1 A control panel 3 is fixedly installed on the top of the thermostatic calorimeter body 1. A self-cleaning mechanism 4 is provided on the left side of the thermostatic calorimeter body 1. A uniform heating mechanism 5 is provided in the inner cavity of the calorimeter 2. The self-cleaning mechanism 4 includes a self-cleaning cylinder 41 , the self-cleaning cylinder 41 is fixedly installed on the left side of the thermostatic calorimeter body 1, the inner cavity of the self-cleaning cylinder 41 is fixedly installed with a center seat 42, and the top of the center seat 42 is detachably connected to the aerobic bomb body 25, self-cleaning A pump 43 is ...

Embodiment 2

[0035] Such as Figure 1-7 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the number of electromagnetic valves 48 is set to two, and the end of the soft water pipe 44 away from the pump 43 is connected to the end of the electromagnetic valve 48 on the left side. The left side is fixedly connected, and the right side of the inner cavity of the self-cleaning cylinder 41 is fixedly equipped with a fan 45, and the air outlet end of the fan 45 is fixedly connected with a heating box 46, and an electric heating wire is arranged in the inner cavity of the heating box 46, and the heating box The bottom of 46 is fixedly connected with an air duct 47, and the end of the air duct 47 away from the heating box 46 is fixedly connected with the right side of the electromagnetic valve 48 located on the right side, and the top of the hollow column 491 extends to the top of the center seat 42 and is fixedly connected with a nozzle Pipe 4...

Embodiment 3

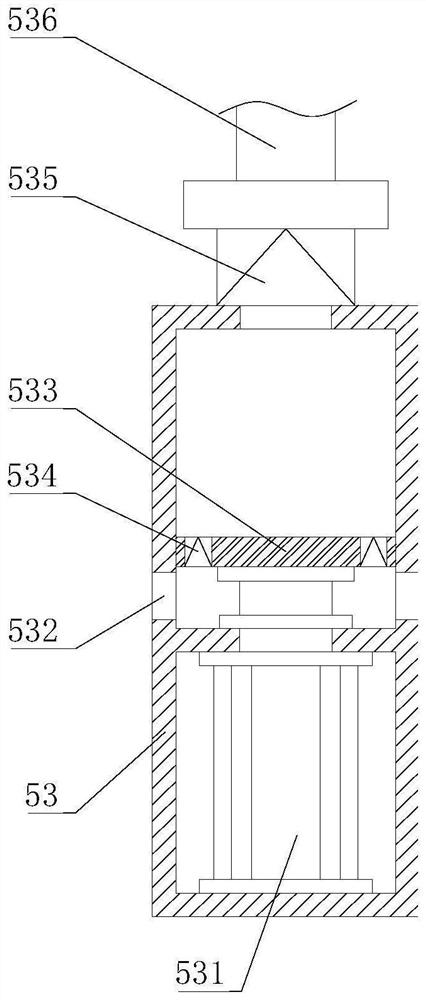

[0037] Such as Figure 1-7 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, a support plate 4941 is fixedly installed in the inner cavity of the collection cylinder 494, and a centrifugal motor 4942 is fixedly installed at the bottom of the support plate 4941. The output shaft of 4942 extends to the top of the support plate 4941 and is fixedly connected with a connecting cylinder 4943. The top of the connecting cylinder 4943 is rotatably connected with a rotating connecting pipe 4944. The top of the rotating connecting pipe 4944 is fixedly connected with the top of the inner cavity of the collecting cylinder 494. Filter screen 4945 is fixedly installed on the outer wall of 4943, self-closing tube 4946 is fixedly connected on the outer wall of connecting cylinder 4943, and fixed inner frame 4947 is fixedly installed in the inner cavity of self-closing tube 4946, and fixed inner frame 4947 is far away from the connection tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com