Packaging detection device for semiconductor production

A detection device and semiconductor technology, applied in semiconductor/solid-state device testing/measurement, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as easy wrist fatigue, easy omission, and inconvenient observation, so as to avoid wrist discomfort, Easy to find abnormalities and avoid missed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

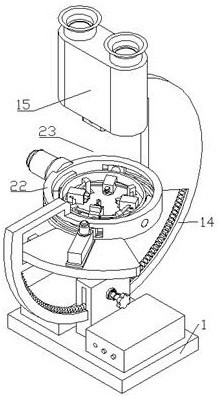

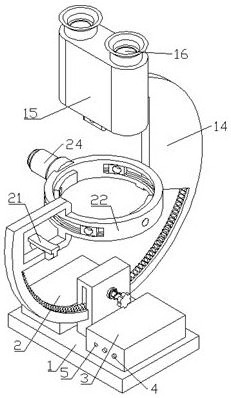

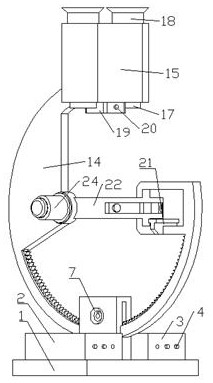

[0019] Such as Figure 1-7 As shown, a packaging and testing device for semiconductor production includes a base 1, a No. 1 battery 2, a No. 2 battery 3, a control button 4, a charging hole 5, a support cylinder 6, a brake ring 7, a radial bearing 8, a gear 9, Adjusting rod 10, brake disc 11, handle 12, No. 1 spring 13, incomplete ring gear frame 14, housing 15, eyepiece 16, objective lens 17, rubber tube 18, lighting lamp 19, adjustment button 20, arc guide rail 21, Support frame 22, swing part 23, described base 1 left part is fixed with No. 1 storage battery 2, and right part is fixed with No. 2 storage battery 3, described No. 1 storage battery 2 and No. Charging hole 5, the control button 4 on the No. 1 storage battery 2 is used to control the inching forward and reverse of the reduction motor 24, and the control button 4 on the No. 2 st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com