Stable mounting device for chip production

A technology for stabilizing packaging and chips, which is applied in the direction of transportation and packaging, conveyor objects, electrical components, etc. It can solve the problems that affect the stability of chip components, and the stability of chip component delivery and extraction is not stable enough, so as to achieve the effect of improving the stability of extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

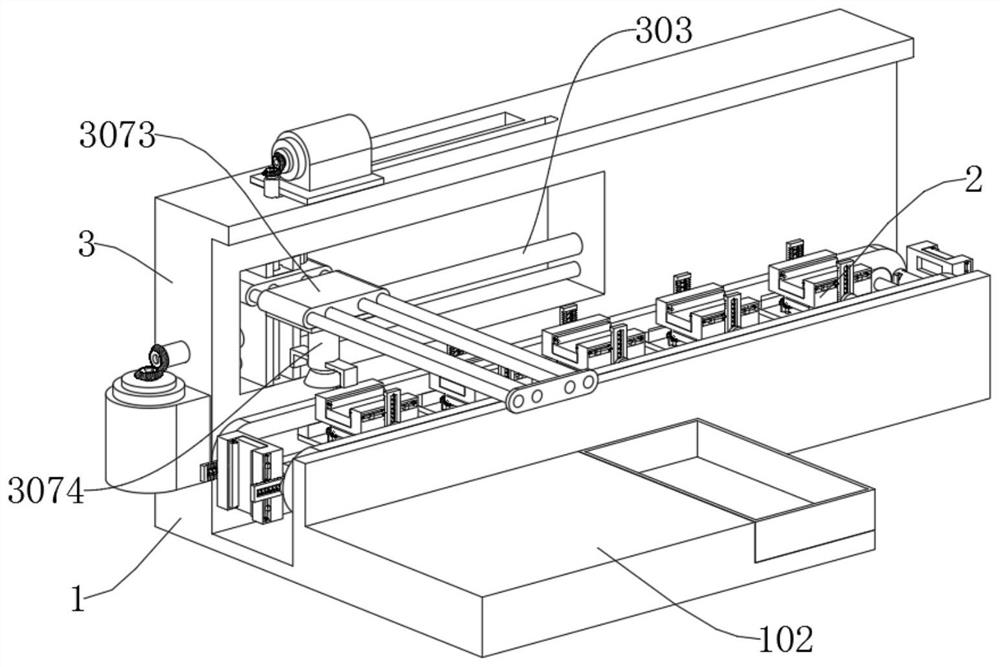

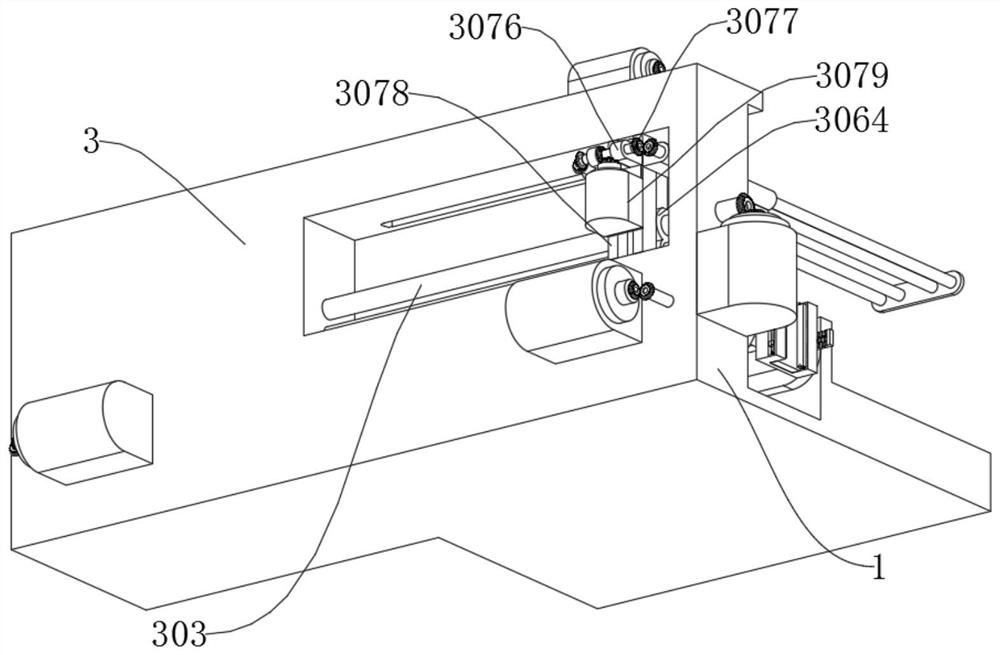

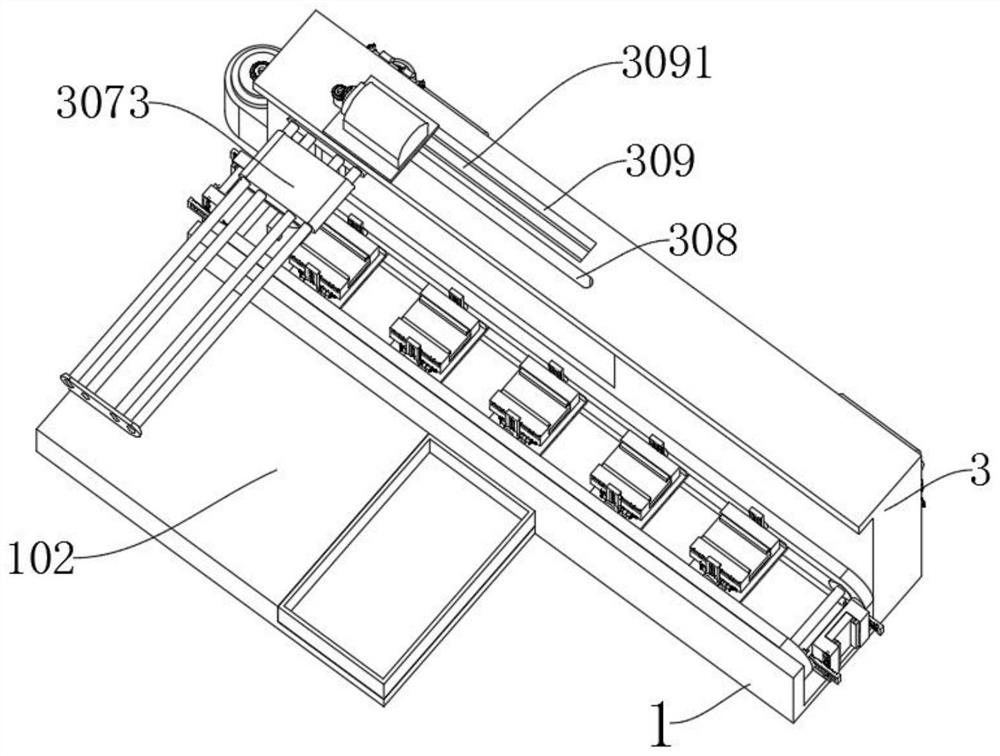

[0045] Example: Please refer to Figure 1 to Figure 9 :

[0046] The present invention proposes a stable mounting device for chip production, including: a transport carrier 1;

[0047] The inner side of the conveying carrier 1 is provided with a preset loading slot 101, and the inner side of the preset loading slot 101 is provided with a drive bearing structure. , and one end of the inner side of the preset loading tank 101 is provided with a driving extrusion structure; install the pillar 2, and install the pillar 2 on the side of the two sets of bearing tooth frames 1061; assemble the carrier 3, and install the assembling carrier 3 on the top end of the conveying carrier 1 At the same time, one side of the assembly carrier 3 is provided with a driving lifting structure, and one side of the assembly carrier 3 is provided with a driving extraction structure, and at the same time, the assembly carrier 3 is provided with a linkage chute 308, and the assembly carrier 3 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com