Quantum dot light emitting diode and preparation method thereof

A quantum dot light-emitting and diode technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of short service life and low luminous efficiency of QLED

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

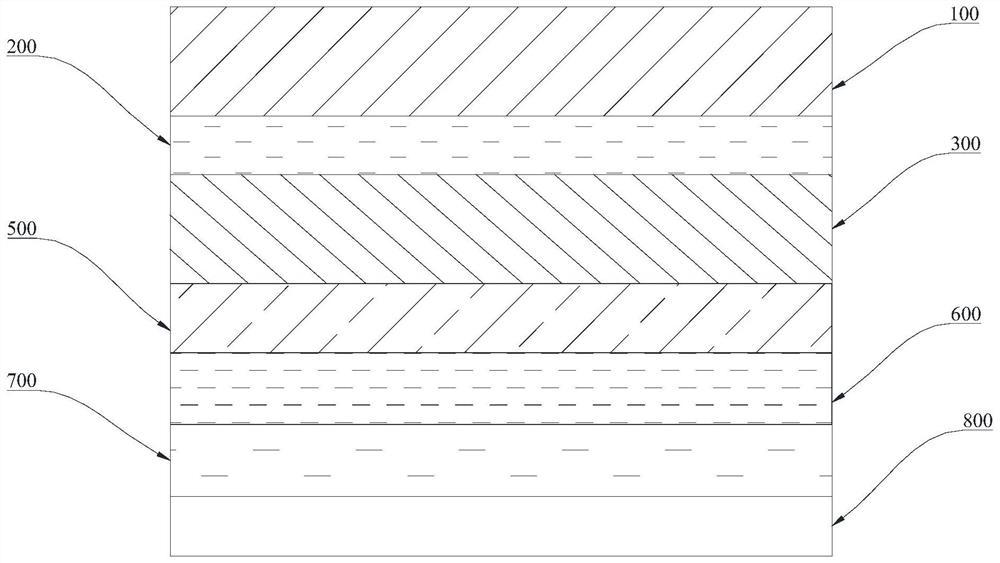

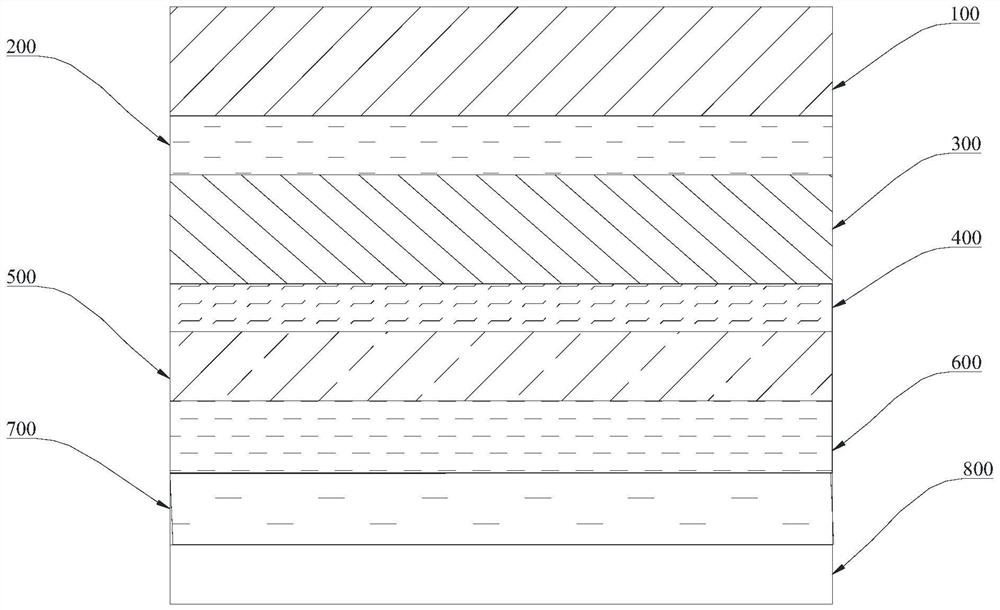

[0034] The preparation method of the above quantum point light emitting diode is as follows:

[0035] The PEDOT: PSS solution is rotated on the ITO glass substrate 800 to form a hole injection layer 600, and after the spin-coated hole injection layer 600, it can also treat 0.1 to 6 h at 60 to 250 ° C to remove the hole injection layer 600. Among the residual solvents avoid the effects of subsequent preparation processes. Specifically, the temperature is typically in the range of 100 to 200 ° C, which may be 100 ° C, 120 ° C, 140 ° C, 150 ° C, 170 ° C or 200 ° C; treatment time is generally from 0.1 to 2 h, may be 0.1H, 0.3H, 0.5 H, 0.8H, 1.2H or 2H; then the organic solution of the hole transporting material of the hole injection layer 600 is then formed to form a hole transport layer 500; after the surface of the hole transport layer 500 is derivatized. The organic solution of the object forms an electronic barrier layer 400, and after the spin coating is formed, the electron blo...

Example Embodiment

[0040] Example 1

[0041] This embodiment provides a quantum dot light emitting diode, and the preparation method thereof is as follows:

[0042] (1) Pedot: PSS solution in the ITO glass substrate 800, PEDOT: PSS solution forms a hole injection layer 600, and heat treatment at 150 ° C for 30 min after completion of the spin coating.

[0043] (2) 8 mg of TFB was completely dissolved in 1 mL of chlorobenzene, and the TFB chlorobenzene solution was applied to the surface of the hole injection layer 600 in the surface of the hole injection layer 600 at a rate of 3000 rpm / min.

[0044] (3) 30 mg of 4,4'-cyclohexyl group 2 [N, N-di (4-methylphenyl) aniline] is completely dissolved in 1 mL of chlorobenzene solution, and then 4,4'-cyclohexyl [N, N-di (4-methylphenyl) aniline] The chlorobenzene solution is applied to the surface of the hole transport layer 500 in the surface of the hole transport layer 500 in the surface of the hole transport layer 500, and the spin coating is 150 ° C. T...

Example Embodiment

[0048] Example 2

[0049] This embodiment provides a quantum dot light emitting diode, and the preparation method thereof is compared to the first embodiment, the main difference is:

[0050] In step (3), 4,4'-cyclohexyl group 2 [N, N-di (4-ethylphenyl) aniline is used for 4,4'-cyclohexylidel [N, N-b) using the same mass of 4,4'-cyclohexylideidin. 4-methylphenyl) aniline] prepared electron blocking layer 400;

[0051] In step (4), the quantum dot light-emitting layer 300 is prepared using a CDSE / ZnS (green) quantum point solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com