Baffle type flood gate for transformer substation

A baffle type, substation technology, applied in distribution substations, substation/distribution device enclosures, substation/switch layout details, etc., can solve the problems of low utilization rate, no flood control effect, troublesome operation, etc. Convenience, good flood control effect, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

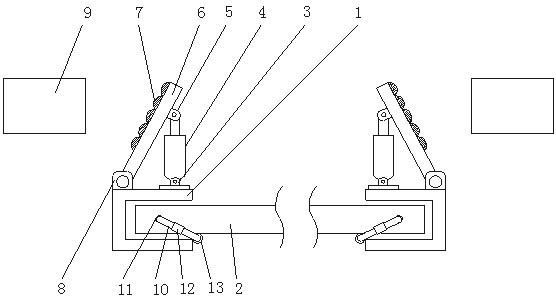

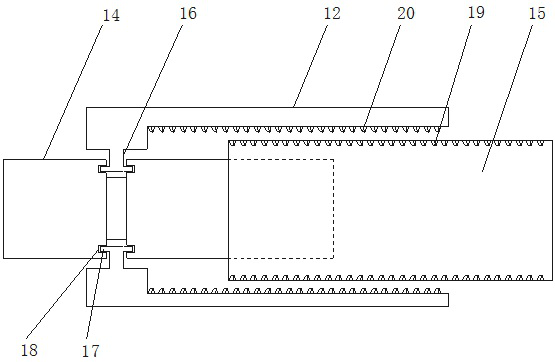

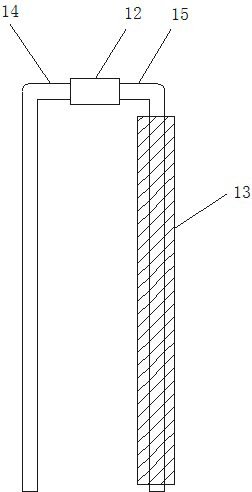

[0020] Such as Figure 1-5 As shown, the baffle type flood control door of the substation includes a U-shaped clamp 1, a water baffle 2 is arranged inside the U-shaped clamp 1, and a first hinge seat 3 is arranged behind the U-shaped clamp 1, so The first hinged seat 3 is fixedly provided with a hydraulic rod 4, the power end of the hydraulic rod 4 is connected with a second hinged seat 5, and the second hinged seat 5 is fixedly arranged on the side baffle 6, and the side baffle The outer surface of the plate 6 is fixedly provided with a sealing strip 7, and the side baffle 5 is connected to the rear of the U-shaped clamp 1 through the third hinge seat 8, and a plurality of water baffles 2 are arranged inside the U-shaped clamp 1. , the two ends of the water retaining plate 2 are provided with insertion holes 11, the insertion holes 11 are provided with a U-shaped fixed rod 10, and the U-shaped fixed rod 10 includes a fixed rod 14, a sliding rod 15 and an adjustment member 12,...

Embodiment 2

[0023] Such as Figure 1-5 As shown, the baffle type flood control door of the substation includes a U-shaped clamp 1, a water baffle 2 is arranged inside the U-shaped clamp 1, and a first hinge seat 3 is arranged behind the U-shaped clamp 1, so The first hinged seat 3 is fixedly provided with a hydraulic rod 4, the power end of the hydraulic rod 4 is connected with a second hinged seat 5, and the second hinged seat 5 is fixedly arranged on the side baffle 6, and the side baffle The outer surface of the plate 6 is fixedly provided with a sealing strip 7, and the side baffle 5 is connected to the rear of the U-shaped clamp 1 through the third hinge seat 8, and a plurality of water baffles 2 are arranged inside the U-shaped clamp 1. , the two ends of the water retaining plate 2 are provided with insertion holes 11, the insertion holes 11 are provided with a U-shaped fixed rod 10, and the U-shaped fixed rod 10 includes a fixed rod 14, a sliding rod 15 and an adjustment member 12,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com