Auxiliary stress application hammer mechanism for operating rod of electric power system

A power system and operating rod technology, which is applied in the field of power system operating rod auxiliary force hammer mechanism, can solve the problems of fragile isolating switch, affecting the normal operation of the power system, and the difficulty and danger of connecting or disconnecting the isolating switch. , to achieve the effect of easy disconnection or connection operation and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

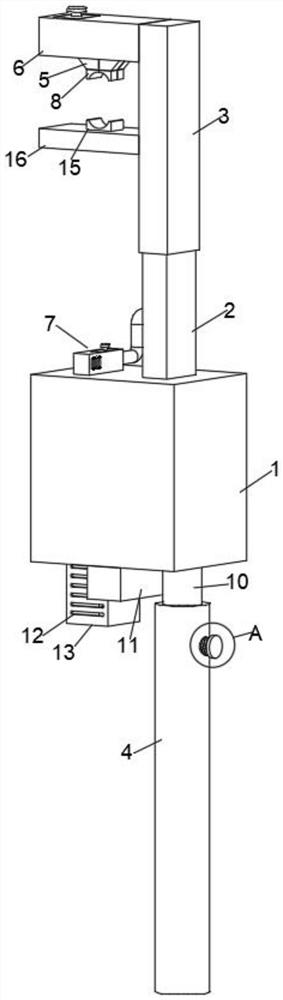

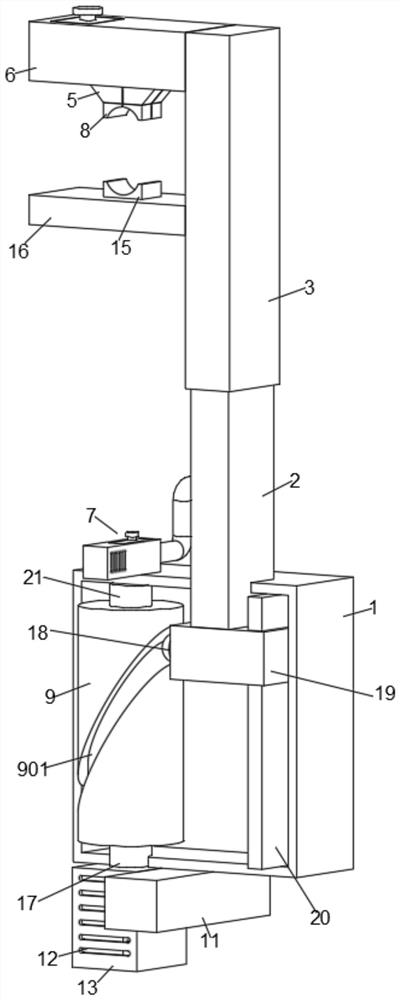

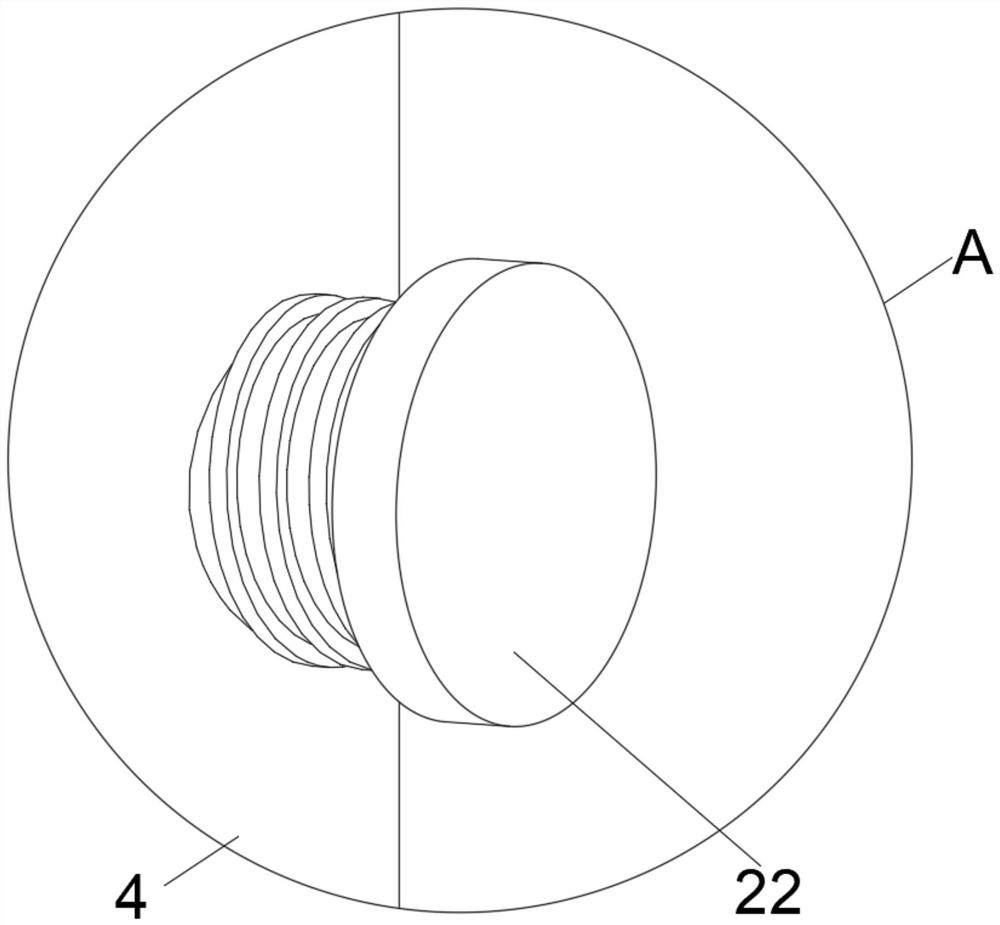

[0027] like figure 1 , Figure 5 As shown, the present invention provides a power system operating rod auxiliary power hammer mechanism, including a mounting box 1, a receiving rod 2, a sliding sleeve 3, a clamping mechanism arranged on the left part of the sliding sleeve, and a clamping mechanism arranged on the installation The adjustment mechanism inside the box is the dust suction assembly arranged on the upper part of the installation box. Specifically, the clamping mechanism includes the storage box 6, the top plate 16 and the first push block 15, the receiving rod 2 is arranged on the upper part of the installation box 1, and the sliding sleeve 3 is set on the upper part of the receiving rod, the left end surface of the sliding sleeve 3 is provided with a storage box 6, the middle part of the left end surface of the sliding sleeve 3 is fixed with a top plate 16, the middle part of the bottom surface of the top plate 16 is provided with a first push block 15, and the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com