An external circulation cooling new energy motor

An external circulation cooling and new energy technology, applied in the direction of motors, cooling/ventilation devices, electric components, etc., can solve the problems of low integration of devices, bloated volume, poor heat dissipation efficiency, etc., to facilitate liquid circulation, cooling liquid Uniform distribution, improve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

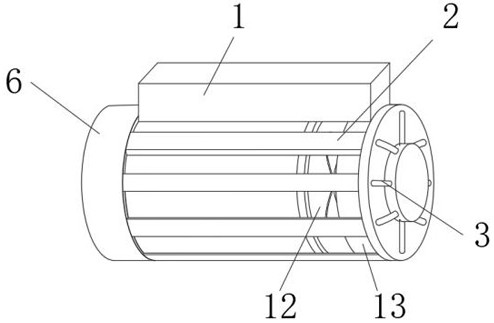

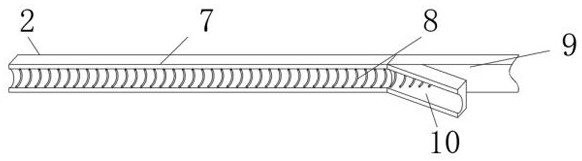

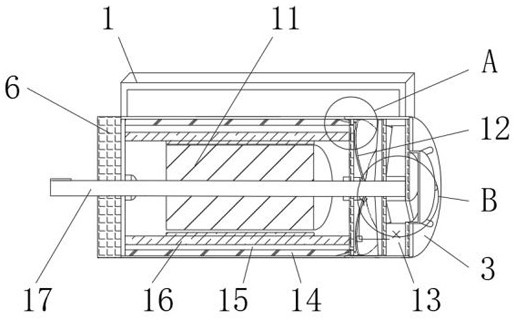

[0030] Such as Figure 1-4 As shown, an external circulation cooling type new energy motor includes a motor main body 6, a liquid storage tank 1 is provided on the top of the motor main body 6, and a heat dissipation mechanism 12 is provided at one end of the motor main body 6, and one side of the heat dissipation mechanism 12 is away from the motor main body 6. The side is connected with a drive mechanism 13, and the end of the drive mechanism 13 away from the heat dissipation mechanism 12 is connected with a drainage sealing plate 3. The surface of the motor body 6 is evenly embedded with a cooling grid 2, and the inside of the motor body 6 is fixedly connected with a stator 16. The motor body The inside of 6 is provided with a cooling chamber 14 for cooling the spoiler 15, the cooling chamber 14 communicates with the liquid storage bin 1, and the cooling grid 2 includes a cooling rod 7, a delivery pipe 8, a connecting rod 9 and a guide rod 10 , the cooling rod 7 is embedded...

Embodiment 2

[0033] On the basis of Example 1, as Figure 1-4 As shown, the conveying pipe 8 inside the heat dissipation rod 7 is arranged spirally against the inner wall of the heat dissipation chamber, and the middle part of the stator 16 drives the rotor 11 , and the middle part of the rotor 11 is provided with a drive shaft 17 .

[0034] When in use, the heat dissipation effect of the heat dissipation cavity on the delivery pipe 8 is effectively improved by spirally arranging the delivery pipe 8 inside the cooling rod 7 .

[0035] Such as Figure 1-6 As shown, the heat dissipation mechanism 12 includes a heat dissipation groove 18, a sealing plate 19 and a scroll blade 20, the sealing plate 19 is fixedly connected to the side end surface of the motor body 6, the heat dissipation groove 18 is opened at the end of the sealing plate 19 away from the motor body 6, and the scroll blade 20 is fixedly connected with the drive shaft 17, and the scroll blade 20 rotates coaxially with the drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com