Medical wound treatment auxiliary device

An auxiliary device and wound technology, applied in medical science, medical equipment, bandages, etc., can solve problems such as troublesome operation, waste of cotton material, excessive cotton material clamping, etc., and achieve the effect of reducing trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

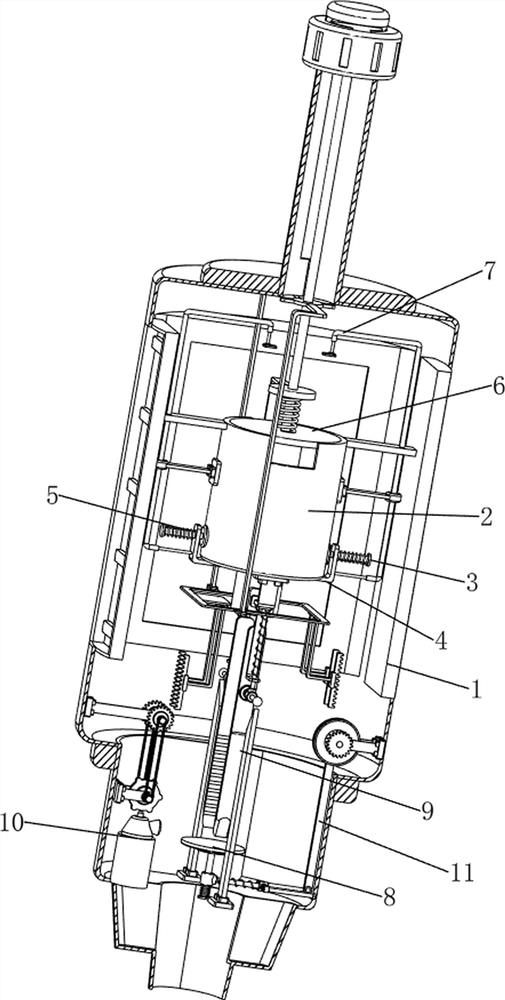

[0073] A medical wound management aid, such as Figure 1-7 As shown, it includes a connecting frame 1, a discharging frame 2, a first connecting rod 3, a cutter 4, a first spring 5, an extruding mechanism 6 and an automatic mechanism 7, and the inner side of the connecting frame 1 is connected with a discharging frame 2. The left and right sides of the bottom of the material frame 2 are welded with a first connecting rod 3, and a cutter 4 is slidably connected on the first connecting rod 3, and a first connecting rod 3 is connected between the outer side of the cutter 4 and the outer end of the first connecting rod 3. The spring 5, the feeding frame 2 is provided with an extruding mechanism 6 that can extrude the cotton material, and the connecting frame 1 is provided with an automatic mechanism 7 that can make the cutter 4 automatically cut the cotton material.

[0074] When wound treatment is required, a certain amount of cotton material needs to be taken out. The cotton mat...

Embodiment 2

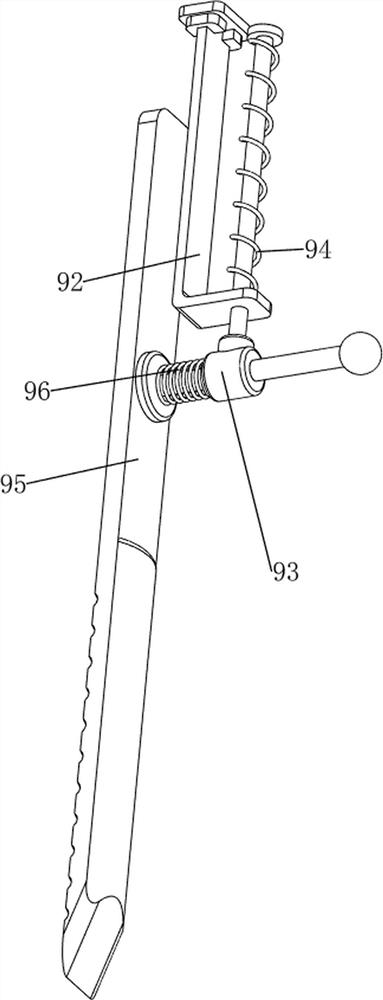

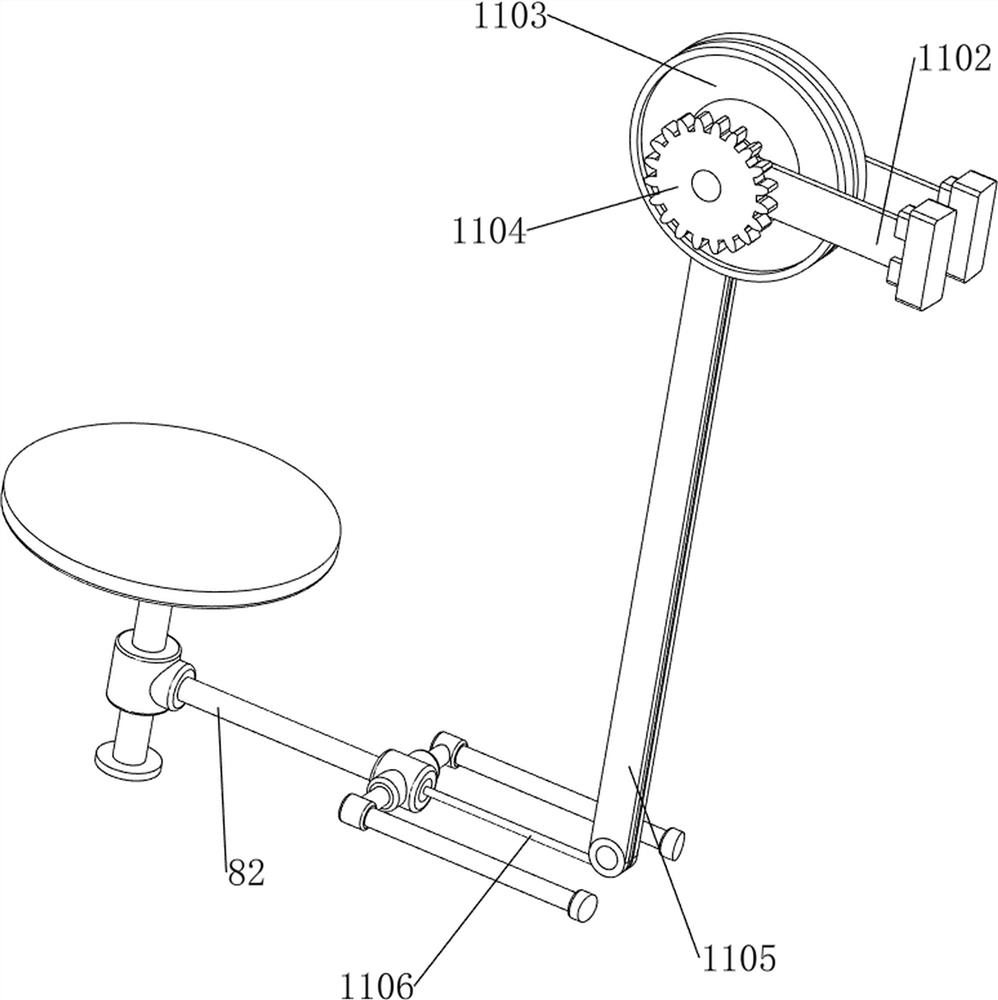

[0079] On the basis of Example 1, such as figure 2 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 and Figure 16 As shown, it also includes a material receiving mechanism 8. The material receiving mechanism 8 includes a second connecting rod 81, a third connecting rod 82, a third spring 83, a material receiving plate 84 and a fourth spring 85. The bottom right of the connecting frame 1 The side inner wall is connected with a second connecting rod 81, the left side of the second connecting rod 81 is slidingly connected with a third connecting rod 82, and the left part of the third connecting rod 82 is connected with the left side of the second connecting rod 81. Three springs 83 , the left part of the third connecting rod 82 is slidably connected with a material receiving plate 84 , and a fourth spring 85 is connected between the lower side of the material receiving plate 84 and the lower side of the third connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com