Wet-type high-speed rust removal system for rolled steel plate strip

A steel strip and wet-type technology, applied in the field of coil steel processing, can solve the problems of poor rust removal effect, rust removal methods and equipment not meeting the actual processing needs, time-consuming and labor-intensive problems, etc., to achieve complete functions, reasonable connection mode and overall working principle Clear, durable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

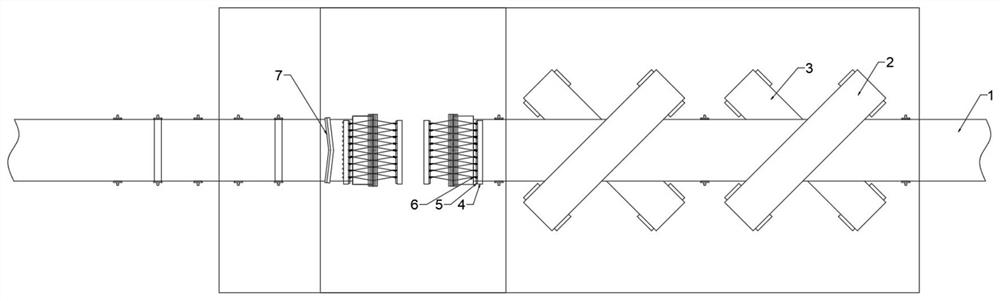

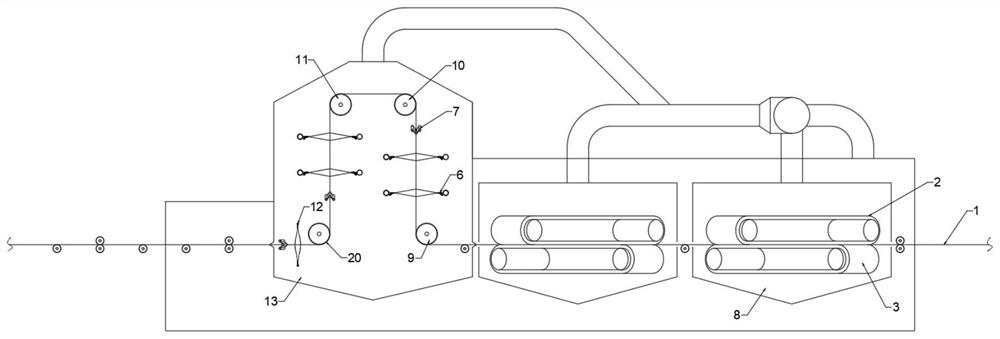

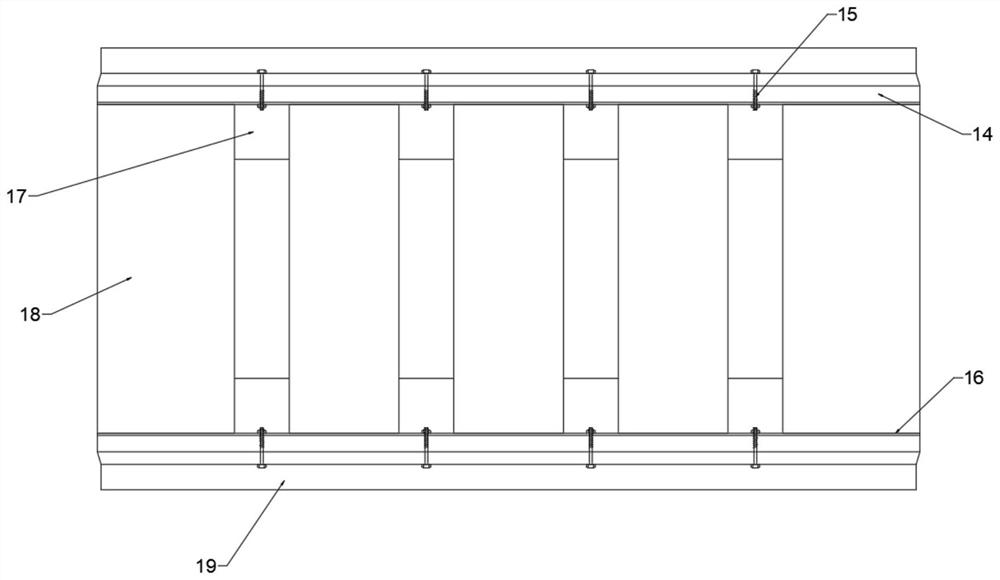

[0022] When the present invention is implemented, such as figure 1 and figure 2 In the shown embodiment, two sets of wire brush roller mechanisms are provided at the front of the conveyor belt. One side is provided with a coil deflection wheel 1 connected with the conveyor belt, two sets of water blasting mechanisms are arranged above the coil deflection wheel 1, a wiper is arranged above the water blasting mechanism, and a wiper is installed above the wiper. There is a coil deflection wheel 2 connected with the conveyor belt, and one side of the coil deflection wheel 2 is connected to the coil deflection wheel 3 through the conveyor belt, and there are two sets of water blasting mechanisms under the coil deflection wheel 3 , There is a wiper board under the water sandblasting mechanism, and a coil plate redirection wheel 4 connected to the conveyor belt i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com