Plastic uptake tray with anti-dripping and anti-collision bottom

An anti-drip and anti-collision technology, applied in rigid containers, containers, packaging and other directions, can solve the problems of increased production costs, reduced storage time, perishable fermentation and deterioration of food, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

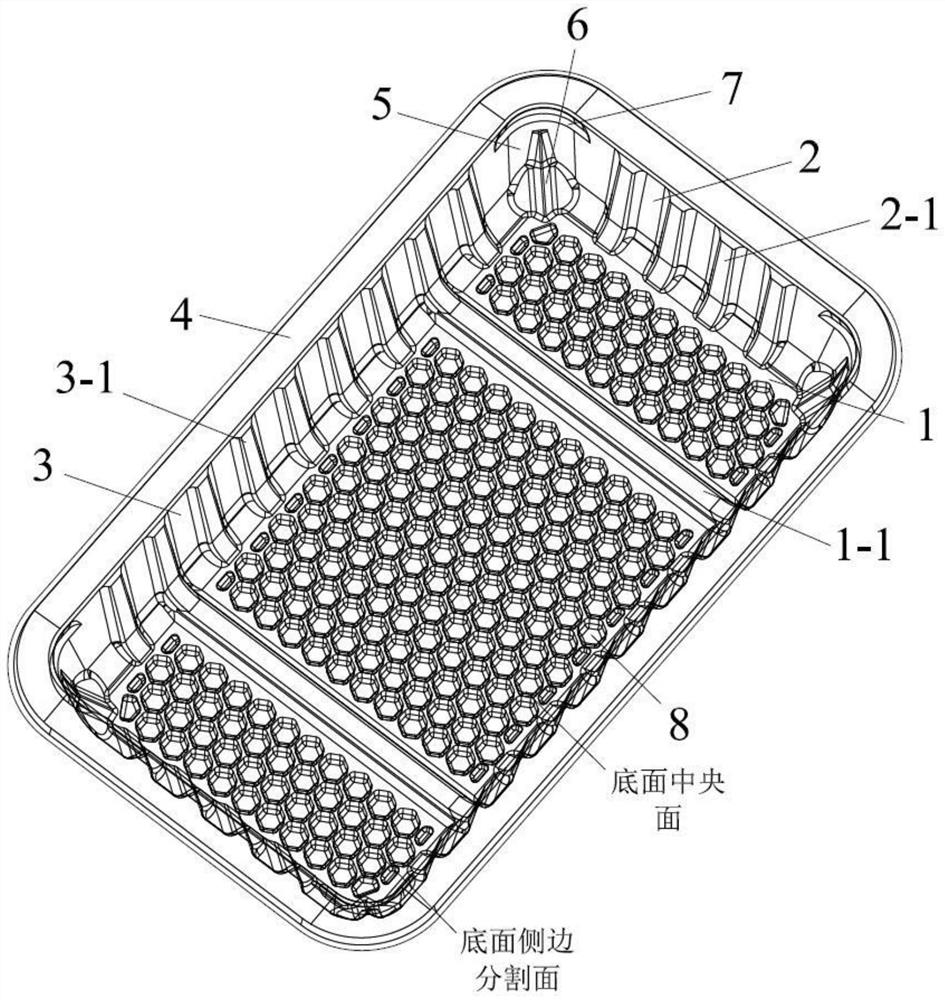

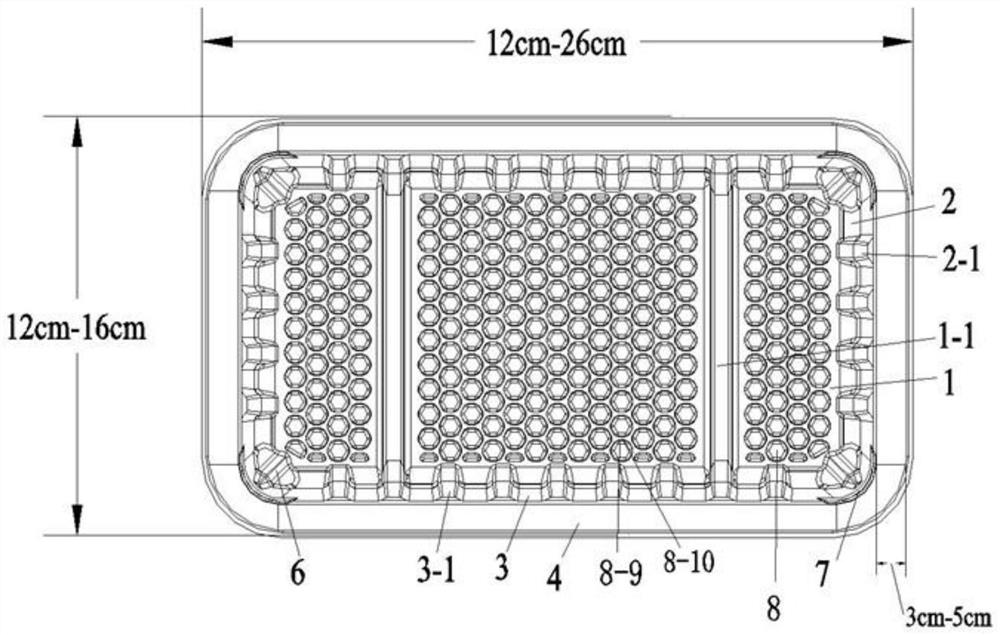

[0046] Such as Figure 1-2 As shown, it is a bottom anti-drip and anti-collision plastic tray provided by the present invention. The tray is a box body formed by a bottom surface 1, a short side side 2 and a long side side 3, and several first ribs 1 are arranged on the bottom surface. -1, several second ribs 2-1 are arranged on the side 2 of the short side, several third ribs 3-1 are arranged on the side 3 of the long side, and the upper edge of the box body is provided with the ribs 2-1 formed by the side 2 of the short side. The edge flanging 4 extending from the long side 3, the corner of the short side 2 and the long side 3 of the box body is provided with a corner arc surface 5, and the corner arc surface 5 is provided with an anti-collision angle 6 at the corner of the bottom of the box body , and the upper edge of the box is provided with an inverted boss 7 that is recessed from the inside of the box to the outside of the box;

[0047] Preferably, as image 3 As show...

Embodiment 2

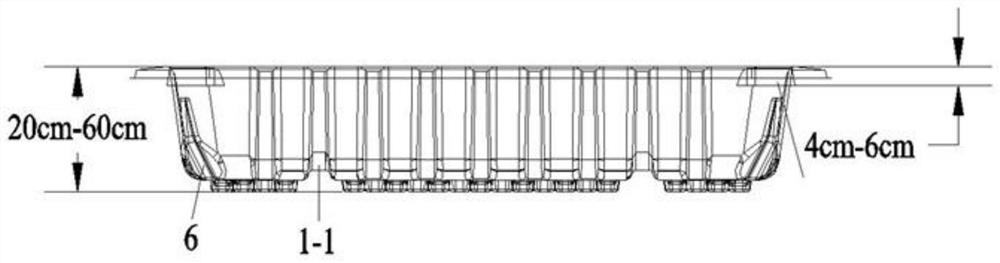

[0076] Such as Figure 11As shown, a bottom anti-drip and anti-collision blister tray provided by the present invention is provided in this embodiment. The tray is a box body formed by a bottom surface 1, a short side side 2 and a long side side 3, and several The first reinforcing rib 1-1, several second reinforcing ribs 2-1 are set on the short side 2, several third reinforcing ribs 3-1 are set on the long side 3, and the box body is provided with a short The edge flanging 4 that edge side 2 and long side 3 extend, box body short side side 2 and long side 3 corners are provided with corner arc surface 5, and corner arc surface 5 is provided with anti-corrosion at box bottom corner. Strike angle 6, and an inverted boss 7 recessed from the inside of the box body to the outside of the box body is provided at the upper edge of the box body;

[0077] The box provided in this embodiment is a box with a higher height, such as Figure 12-Figure 13 As shown, its height is 40-60cm, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com