Concrete water reducing agent as well as preparation method and application thereof

A concrete water reducing agent and water solution technology, which is applied in the field of concrete building materials, can solve the problems of early strength effect, long concrete setting time, insufficient slump retention performance, etc., and achieves delaying hydration reaction, improving water solubility and electrocatalysis The effect of enhancing the slump protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

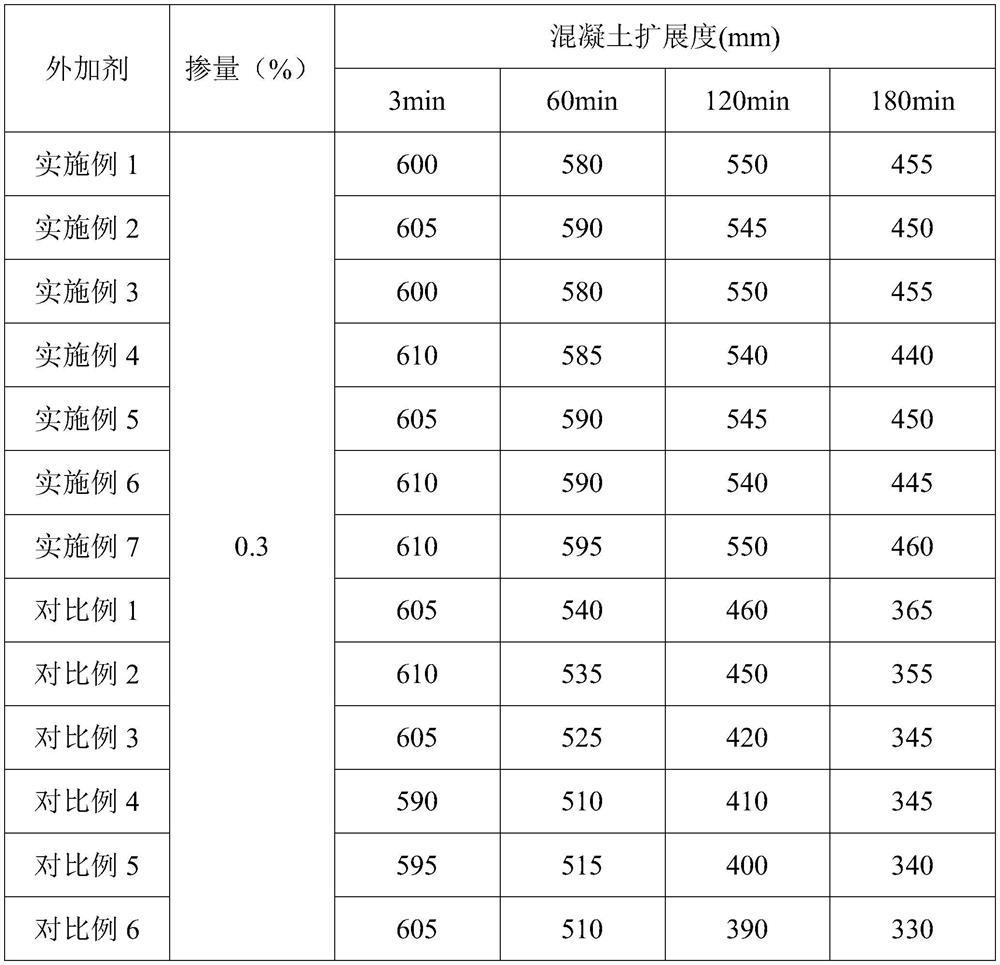

Examples

Embodiment 1

[0027] This embodiment provides a concrete water reducer and its preparation method, wherein the water reducer is made of the following raw material components by weight: 330 parts by weight of methallyl polyoxyethylene ether, 400 parts by weight of water, thioglycolic acid 3 parts by weight, 29 parts by weight of acrylic acid, 1.8 parts by weight of hydrogen peroxide, 0.4 parts by weight of vitamin C, 1.5 parts by weight of graphene oxide, 18 parts by weight of caustic soda, and 15 parts by weight of methyl 2-chloroacrylate.

[0028] Concrete preparation method comprises the following steps:

[0029] (1) Take 1.5 parts by weight of graphene oxide and 300 parts by weight of water into the reaction kettle, turn on the high-power industrial-grade continuous flow energy-concentrating ultrasonic disperser, the control parameters are: ultrasonic frequency 20±1kHz, ultrasonic power 3000W, ultrasonic 15min, then add 18 parts by weight of caustic soda and 15 parts by weight of 2-chlor...

Embodiment 2

[0033] This embodiment provides a concrete water reducer and its preparation method, wherein the water reducer is made of the following raw material components in parts by weight: 370 parts by weight of methallyl polyoxyethylene ether, 440 parts by weight of water, isopropyl 4 parts by weight of alcohol, 37 parts by weight of methacrylic acid, 2.2 parts by weight of ammonium persulfate, 0.8 parts by weight of sodium bisulfite, 2 parts by weight of graphene oxide, 19 parts by weight of caustic soda, and 16 parts by weight of 2-chloroacrylic acid.

[0034] Concrete preparation method is with embodiment 1.

Embodiment 3

[0036] This embodiment provides a concrete water reducer and its preparation method, wherein the water reducer is made of the following raw material components in parts by weight: 410 parts by weight of methallyl polyoxyethylene ether, 470 parts by weight of water, mercaptopropylene 4.8 parts by weight of acid, 49 parts by weight of citraconic acid, 2.6 parts by weight of hydrogen peroxide, 0.4 parts by weight of ferrous sulfate, 3 parts by weight of graphene oxide, 20 parts by weight of caustic soda, and 18 parts by weight of 2-chloroacrylic acid.

[0037] Concrete preparation method is with embodiment 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap