A kind of yield strength 2000mpa grade alloy steel and preparation method thereof

A technology of yield strength and alloy steel, applied in the field of alloy steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

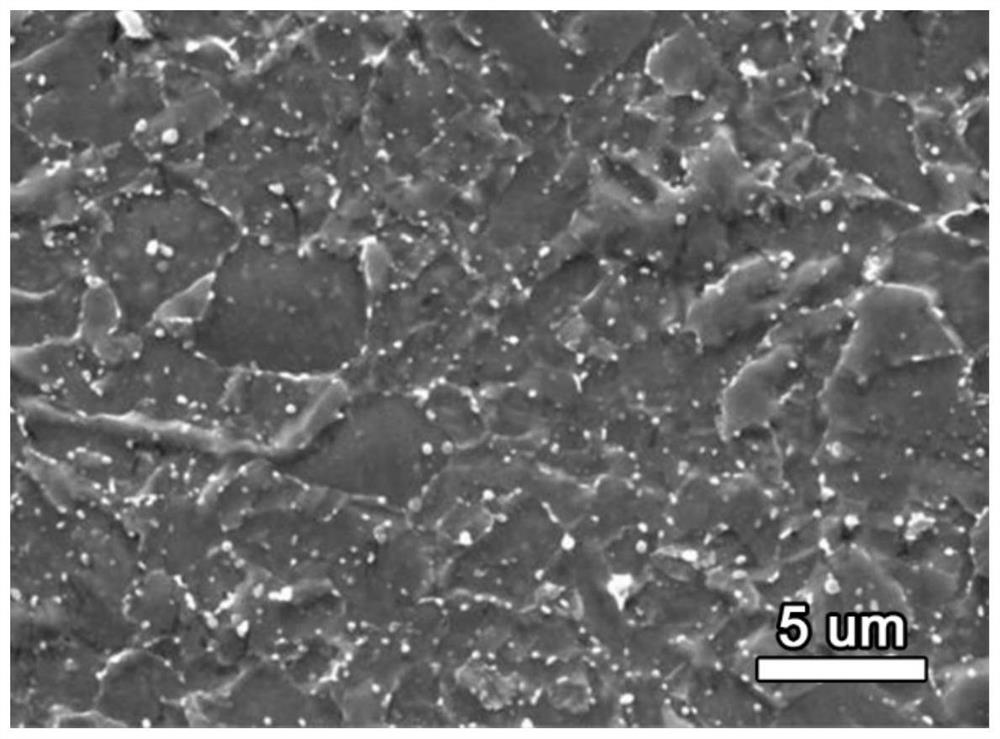

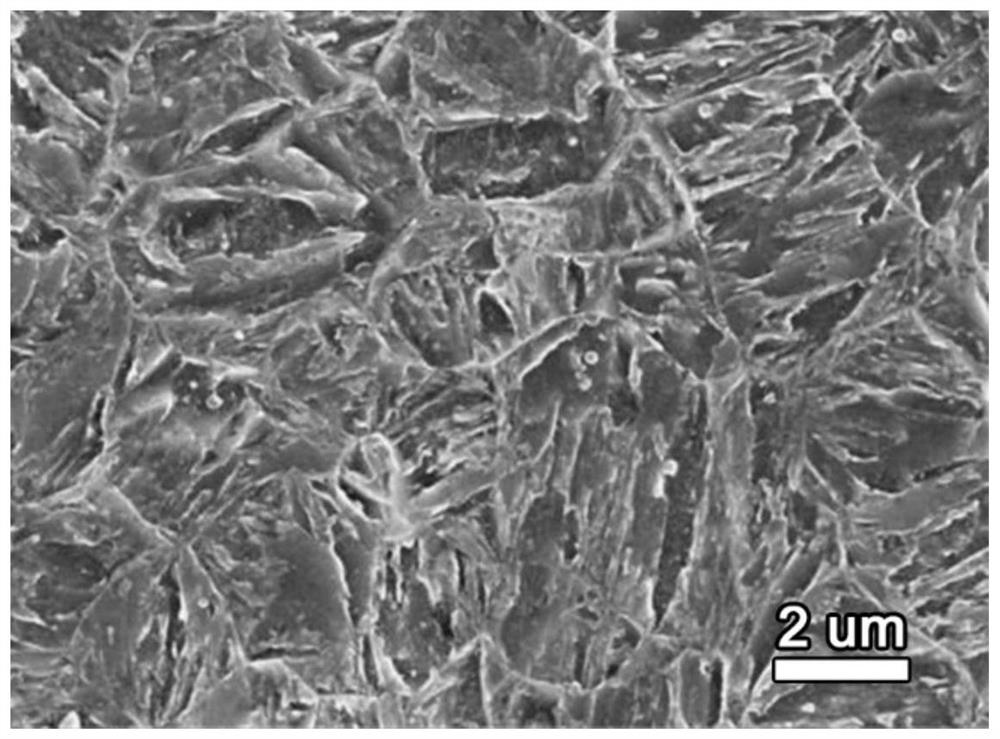

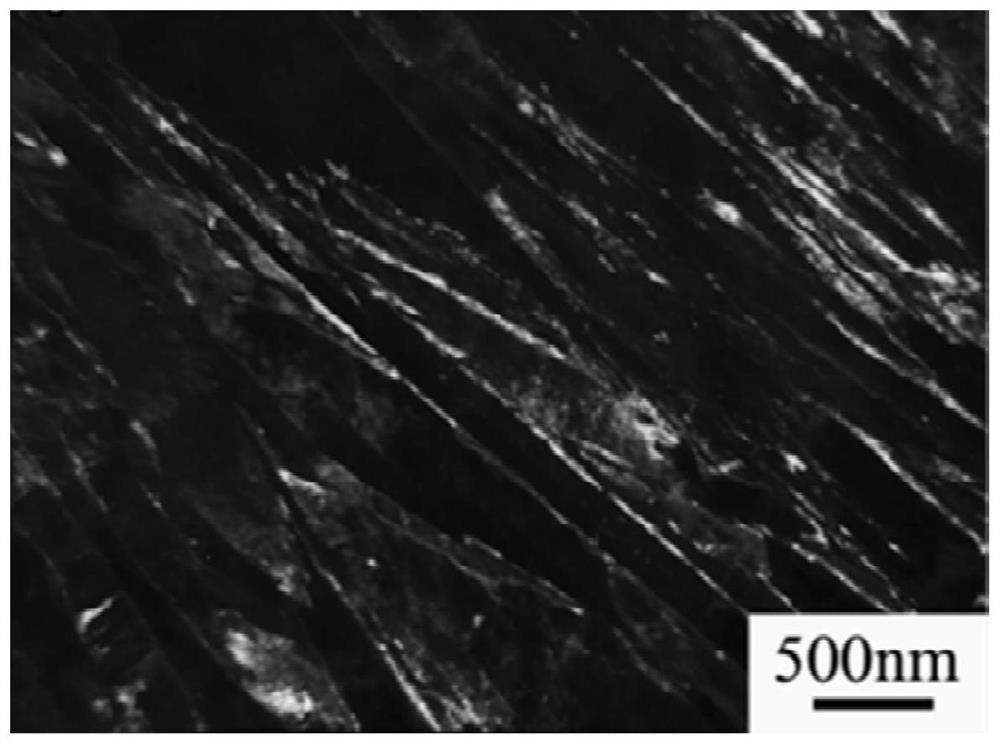

Image

Examples

Embodiment Construction

[0020] A 50 kg vacuum induction furnace was used to prepare 5 furnaces of steel ingots such as CD1-CD5. The specific components are shown in Table 1. The steel ingots were peeled and the risers were cut off before billet forging. The heating temperature of the second fire forging is 1100 ℃, the heating temperature of the third fire forging is 1050 ℃, and it is forged into a Ф18mm bar. After forging, the bar is first annealed: 900 ℃ for 30 minutes, oil quenching, 680 ℃ for 3 hours, furnace cooling. Chemical analysis, tensile, and impact specimens were then taken from the bars. Tensile and impact samples were quenched and tempered to measure tensile properties, impact toughness and mechanical properties. The chemical composition results are shown in Table 1.

[0021] Table 1 Chemical composition of laboratory-prepared steel (wt.%)

[0022] Element C Cr Si Al Mn Mo V Nb Ti S P Fe CD1 0.40 2.0 1.0 0.5 2.0 1.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com