A kind of low-cost thick and heavy q355e hot-rolled h-section steel and its manufacturing method

A H-beam, low-cost technology, applied in the direction of metal rolling, etc., can solve the problems of high price, shortage of resources, and large price fluctuations, and achieve the effect of small particles and saving strategic resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A low-cost 460MPa-grade, excellent low-temperature toughness hot-rolled H-beam steel of this embodiment includes the following components by weight: C: 0.10%; Si: 0.10%, Mn: 1.00%; Nb: 0.03%; Ti: 0.01% ; N: 0.004%, and the rest is iron and other impurities. This embodiment realizes the manufacture of low-cost thick and heavy Q335E hot-rolled H-beam products through low-cost composition design and optimized process coordination, filling the domestic blank of heavy and heavy H-beam steel. , which saves Ni's strategic resources and achieves green manufacturing of products.

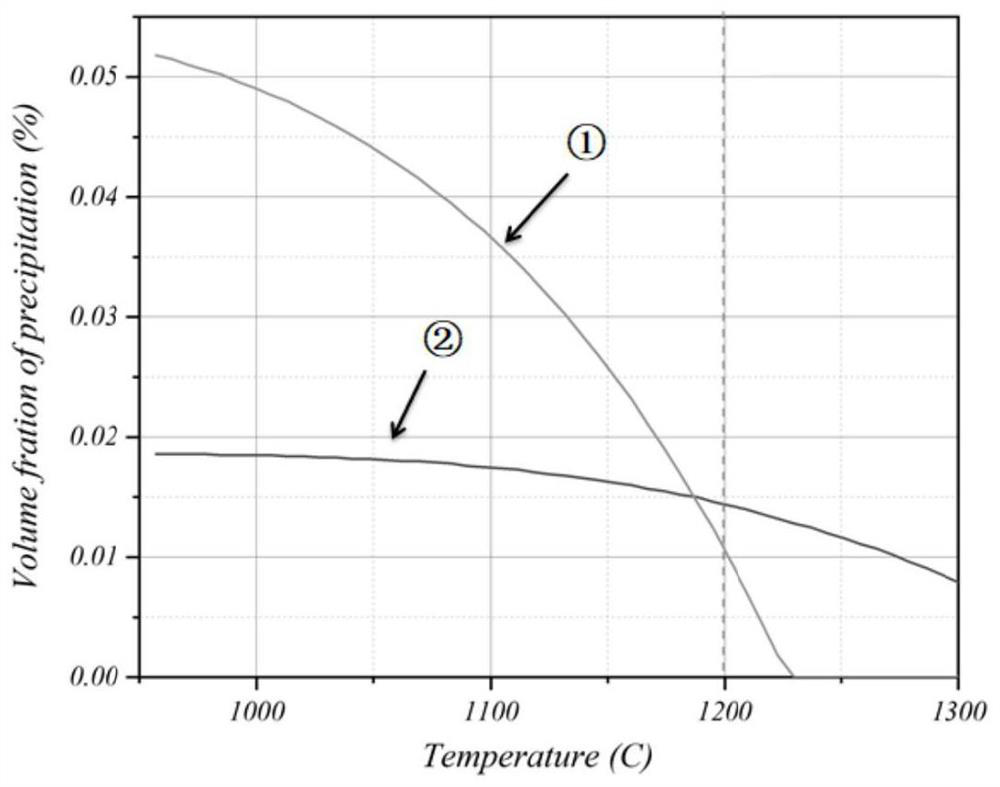

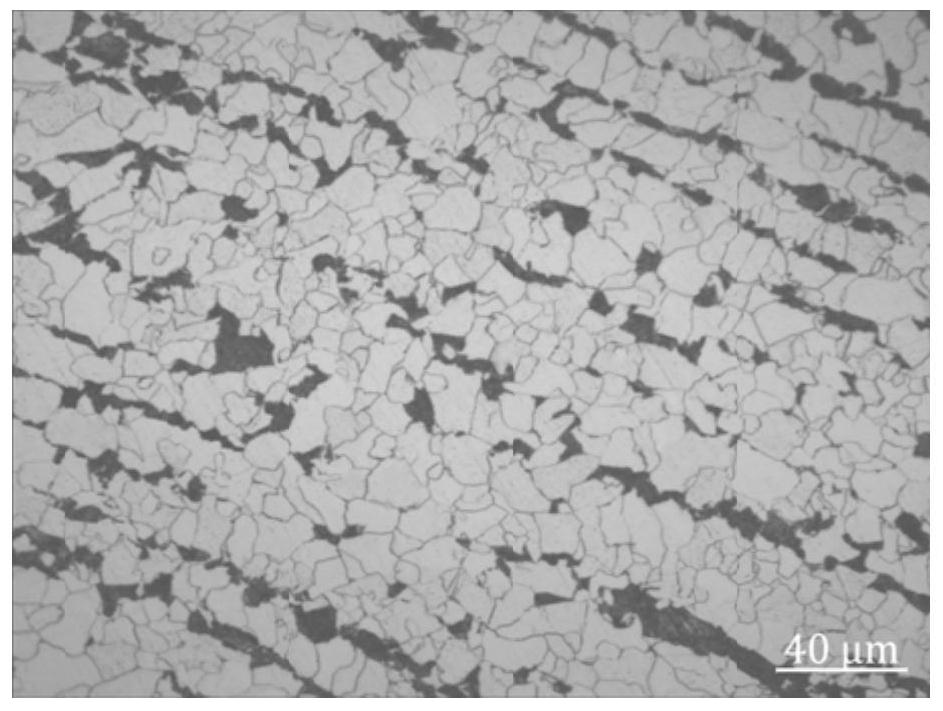

[0045] In this embodiment, the product of Ti and N ranges from 0.00004% to 0.0007%. The product of Ti and N mainly controls the size and distribution of the TiN second-phase particles to ensure that the TiN second-phase particles are fine and uniformly dispersed. The particle size of the second phase of TiN is coarse, and the distribution per unit area is not uniform. In this embodiment, the microallo...

Embodiment 2

[0054] A low-cost and heavy Q355E hot-rolled H-beam steel of this embodiment is basically the same as that of Embodiment 1, except that it includes the following components by weight: C: 0.18%; Si: 0.60%, Mn: 1.60% ; Nb: 0.05%; Ti: 0.015%; N: 0.003%, the rest are iron and other impurities, and the product of Ti and N is 0.000045%. In this example, the flange thickness of the finished H-beam is 80mm, the yield strength is 413MPa, the tensile strength is 590MPa, the elongation after fracture is 25%, and the impact toughness at -40°C is 122J; The particle size was 9.3 microns.

[0055] The production method of a low-cost, thick and heavy Q355E hot-rolled H-beam in this embodiment, the basic process is the same as that in Embodiment 1, and the difference is that in this embodiment, the rolling start temperature is controlled in the rough rolling process of the blanking machine: 1042° C., the rolling deformation is 20%, the roll diameter is 1400 mm, and the rolling speed is 4.0 m / ...

Embodiment 3

[0061] A low-cost and heavy Q355E hot-rolled H-beam steel of this embodiment is basically the same as that of Embodiment 1, except that it includes the following components by weight: C: 0.13%; Si: 0.42%, Mn: 1.45% ; Nb: 0.04%; Ti: 0.012%; N: 0.004%, the rest are iron and other impurities, and the product of Ti and N is 0.000048%. In this example, the flange thickness of the finished H-beam is 75mm, the yield strength is 413MPa, the tensile strength is 590MPa, the elongation after fracture is 25%, and the impact toughness at -40°C is 122J; The particle size was 8.9 microns.

[0062] The production method of a low-cost, thick and heavy Q355E hot-rolled H-beam in this embodiment, the basic process is the same as that in Embodiment 1, and the difference is that in this embodiment, the rolling start temperature is controlled in the rough rolling process of the blanking machine: At 1030°C, the rolling deformation is 18%, the roll diameter is 1400 mm, and the rolling speed is 3.0 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com