One-hole and one-measurement monitoring device for coal mine drill site extraction and detection method of one-hole and one-measurement monitoring device

A technology for monitoring devices and drilling sites, applied in mining devices, safety devices, earthwork drilling and mining, etc., can solve the problems of missed inspection, fraud, missed inspection, and high cost, so as to simplify inspection personnel, reduce costs, and speed up inspections. speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

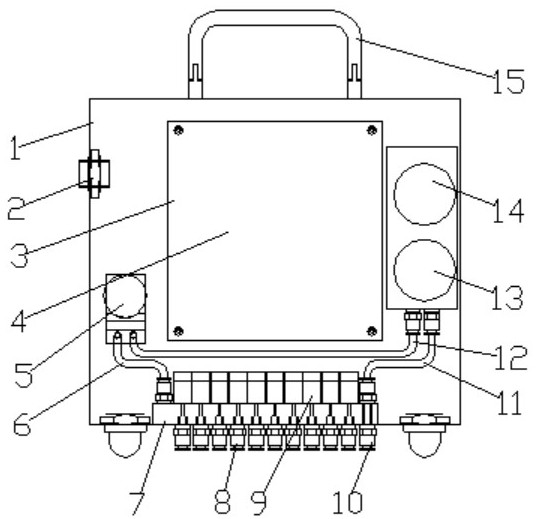

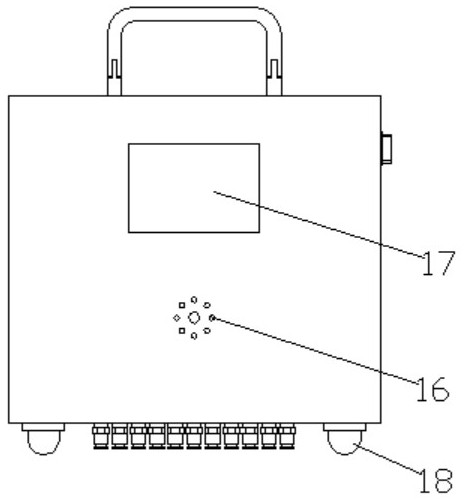

[0017] Example: such as Figure 1 to Figure 4 As shown, it includes a fixed housing 1. The fixed housing 1 is a rectangular box structure. A bus bar 7 is provided at the relative position on the bottom side of the fixed housing 1. A plurality of air intake quick connectors 8 are installed on the bottom of the bus bar 7. The air intake quick connectors 8 runs through the bottom of the fixed housing 1 downwards, and the air intake quick joint 8 is located outside the fixed housing 1, and a plurality of electromagnetic valves 9 are installed on the top of the bus bar 7, and the number positions of the plurality of electromagnetic valves 9 are respectively corresponding to those of the plurality of air intake quick joints 8. Corresponding to the quantity and position, a plurality of inlet quick connectors 8 are opened and closed through the control of a plurality of solenoid valves 9, the left end of the bus bar 7 is provided with an inlet gas main pipe 6, the right end of the bus ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com