Automobile engine manifold air inlet system based on MEMS pressure sensor

A technology for automobile engines and pressure sensors, which is applied in the direction of machines/engines, engine components, and charging systems, etc., which can solve the problems of decreased accuracy of data collected by MEMS pressure sensors and decreased sensitivity of sensitive components, so as to avoid impact damage and improve cleanliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

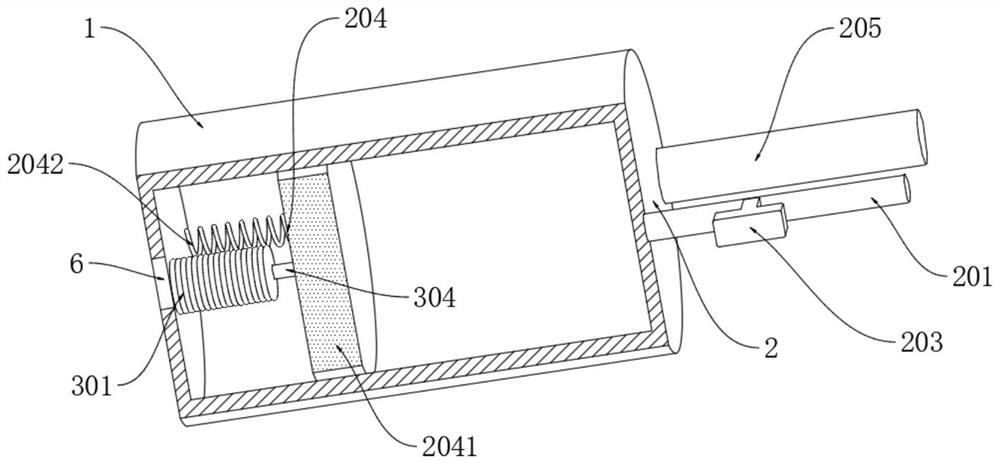

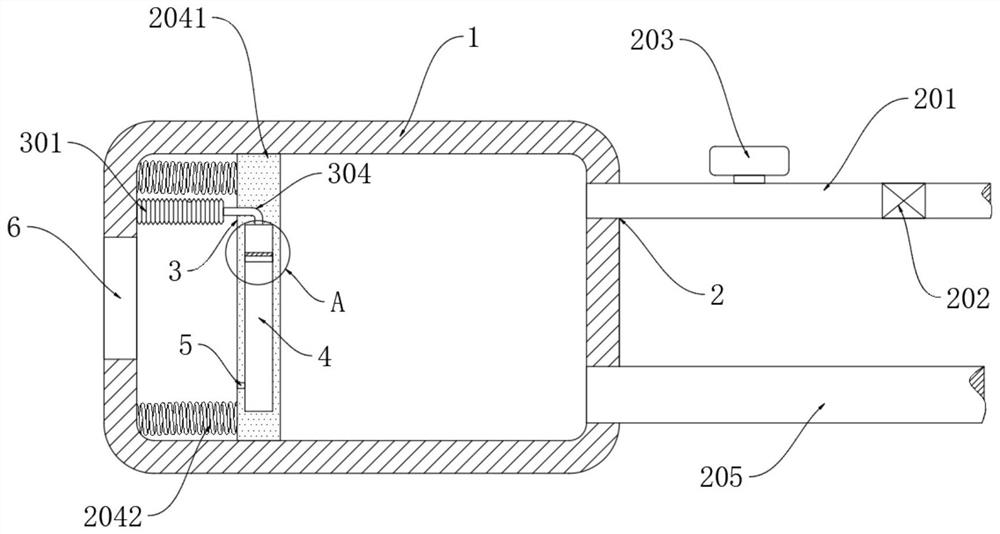

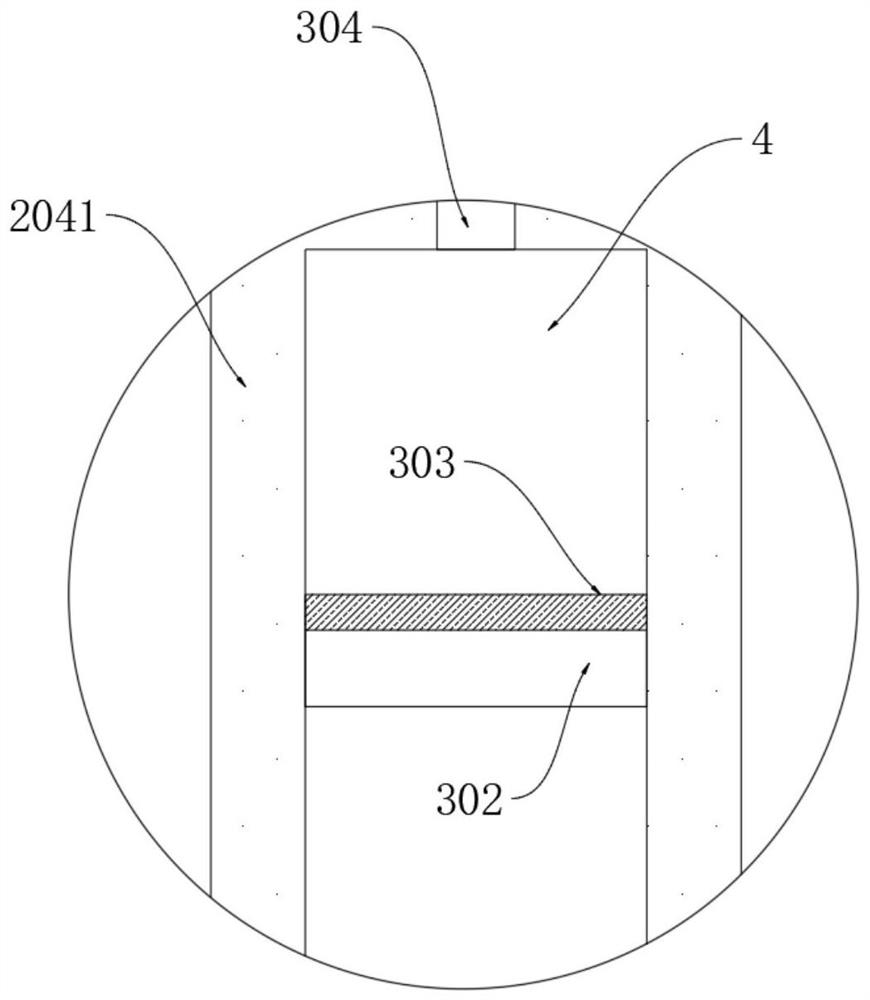

[0027] refer to Figure 1-3 , an automobile engine manifold intake system based on a MEMS pressure sensor, comprising a sealing cylinder 1, a monitoring air supply device 2 for supplying air to the engine manifold is installed in the sealing cylinder 1, and the monitoring air supply device 2 includes an air suction pipe 201 , check valve 202, MEMS air pressure sensor 203, flow conversion mechanism 204 and air outlet pipe 205, and the pipe diameter of air outlet pipe 205 is greater than the pipe diameter of suction pipe 201; On the inner wall of sealing cylinder 1, there is an air port 6, and the air suction pipe 201 and the air outlet pipe 205 are connected with the inside of the sealed cylinder 1, the MEMS air pressure sensor 203 is installed on the suction pipe 201, and the check valve 202 is installed in the suction pipe 201. Specifically, the MEMS air pressure sensor 203 and the check valve 202 The installation methods are all mature technologies, and the check valve 202 a...

Embodiment 2

[0037] refer to Figure 4-6 , different from Embodiment 1, the side wall of the rubber slide plug 2041 is provided with a rotary groove 7, and a circulation device 8 for continuous circulation and purification of the air is installed in the rotary groove 7. The circulation device 8 includes a rubber column 801, an iron sheet 802, Telescopic bellows 803, two scrapers 804 and permanent magnet sheet 805. Specifically, fur is fixedly arranged on the iron sheet 802, so that when the iron sheet 802 moves up and down, the fur on the iron sheet 802 can rub against the inner wall of the strip groove 9 to cause static electricity on the surface of the rubber column 801.

[0038] The rubber column 801 is sealed and rotatably connected in the rotary groove 7, and the inner bottom of the rotary groove 7 is provided with a groove 11, and a spring shaft 12 is rotatably connected in the groove 11, and the spring shaft 12 is fixedly connected with the rubber column 801, and the strip groove 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com