A cryogenic ball valve and method of using the same

A technology of cryogenic and ball valves, applied in control valves, valve devices, valve details, etc., can solve problems such as easy leakage, large shrinkage, and valve rupture, and achieve simple structural design, uniform contact stress, and improved sealing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

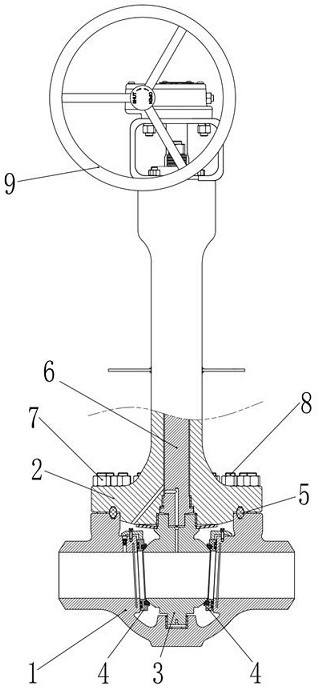

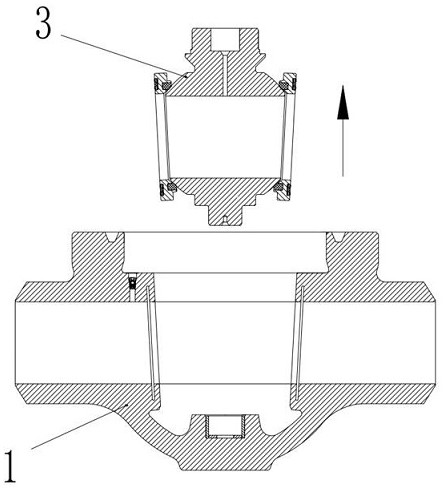

[0046] as attached figure 1 -Attached Figure 7 As shown, the present invention provides a cryogenic ball valve, which includes: a valve body 1, a valve cover 2, a ball body 3, and a valve seat assembly 4; wherein, the upper end of the valve body 1 is provided with an opening and a mounting surface, The mounting surface and the lower flange of the valve cover 2 are connected by bolts 8 and nuts 7; the ball 3 and the valve seat assembly 4 are installed into the valve body 1 from the opening, and the two symmetrically arranged valve seat assemblies 4 are connected to the valve body on both sides respectively. The sealing surface on 1 and the ball body 3 are in sealing contact; the valve cover 2 is provided with a valve stem 6, and the upper side of the valve cover 2 is provided with a manual operator 9, which is connected with the ball body 3 through the valve stem 6. 3. A first boss is arranged on the upper side, and a disc spring 10 is arranged between the ball 3 and the valv...

Embodiment 2

[0050] Preferably, on the basis of Embodiment 1, Embodiment 2 is provided with a damping check valve 12 on the second boss, the damping check valve 12 includes a check valve body, and the check valve body is provided with a spherical valve core and a first A coil spring 12.1, one end of the first coil spring 12.1 is against the check valve body, and the other end is against the spherical valve core. The damping check valve 12 adjusts the valve central chamber 40 to the valve central chamber 40 according to the pressure value of the valve central chamber 40. The upstream valve chamber 20 or the downstream valve chamber 30 is selectively communicated or closed. to attach Image 6 As shown in the example, the damping check valve 12 has only one-way flow capacity, that is, the medium can only flow from the valve middle cavity 40 to the upstream valve cavity 20 , and cannot flow from the upstream valve cavity 20 to the valve middle cavity 40 . By adjusting the pre-tightening force...

Embodiment 3

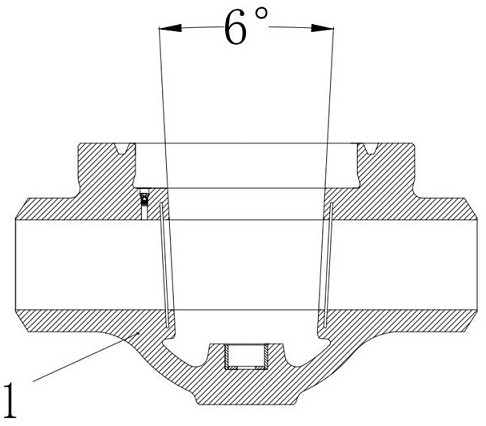

[0053] In order to further improve the sealing performance of the cryogenic ball valve of the present invention, Embodiment 3 makes the following optimizations on the basis of Embodiments 1 and 2. as attached Image 6 -Attached Figure 8 As shown in , the cryogenic ball valve of the present invention is also provided with a first elastic ring groove 13 and a second elastic ring groove 14 at the second bosses of the upstream valve cavity 20 and the downstream valve cavity 30 of the valve body 1, respectively. The elastic ring groove 13 and the second elastic ring groove 14 are substantially parallel to the sealing surface; wherein the ratio of the groove width d of the first elastic ring groove 13 and the second elastic ring groove 14 to the distance D from the sealing surface is 0.4-0.5, Preferably it is 0.4; the ratio of the groove depth h of the first elastic ring groove 13 and the second elastic ring groove 14 to the thickness H of the second boss is 0.5-0.6, preferably 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com