Parameter selecting and matching method for shock absorber of inertial measurement unit

A shock absorber and component technology, applied in instruments, measuring devices, etc., can solve the problems of cumbersome process and slow generation process, and achieve the effect of flexible selection and clear method and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

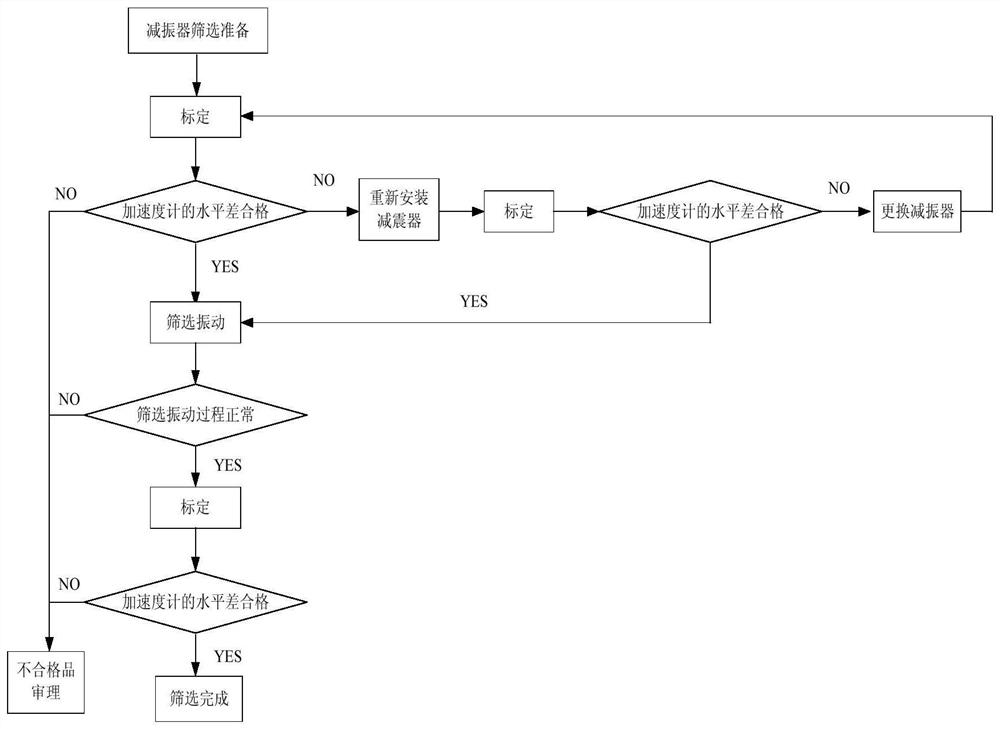

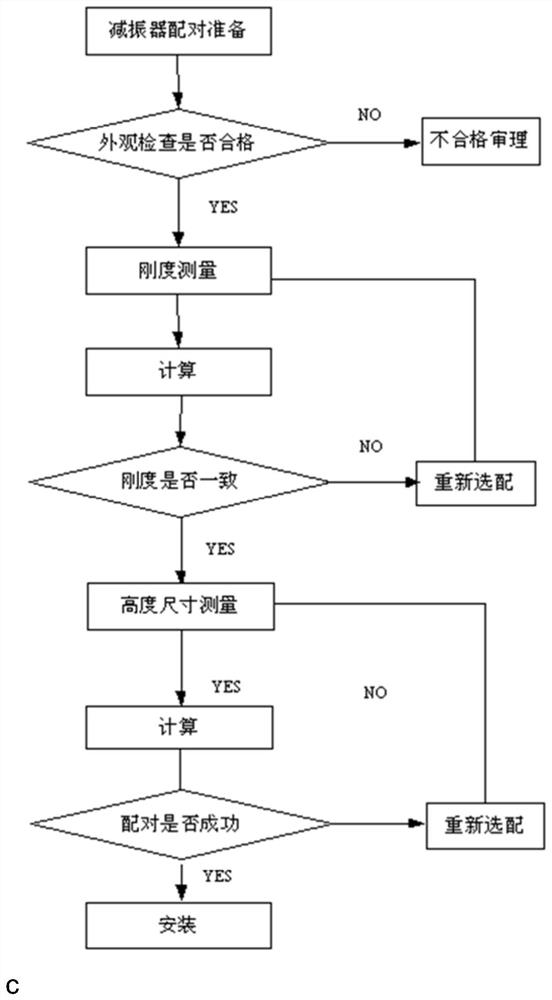

[0031] A parameter selection method for inertial group shock absorbers, aimed at such as figure 1 The selection process of the existing shock absorber shown is improved, and the performance parameters of a single shock absorber can be matched to make the shock absorber system meet the requirements of use. The installation method of the shock absorber for the current inertial sensitive parts of the laser inertial group is roughly divided into For four-point or eight-point symmetrical arrangement on two opposite mounting surfaces of components, it is necessary to match the height dimension of the shock absorber, confirm the deformation amount, and calculate the stiffness, such as image 3 As shown, the specific process is as follows:

[0032] (1) Conduct visual inspection of the shock absorber, and select shock absorber products that meet the surface defect-free and size requirements;

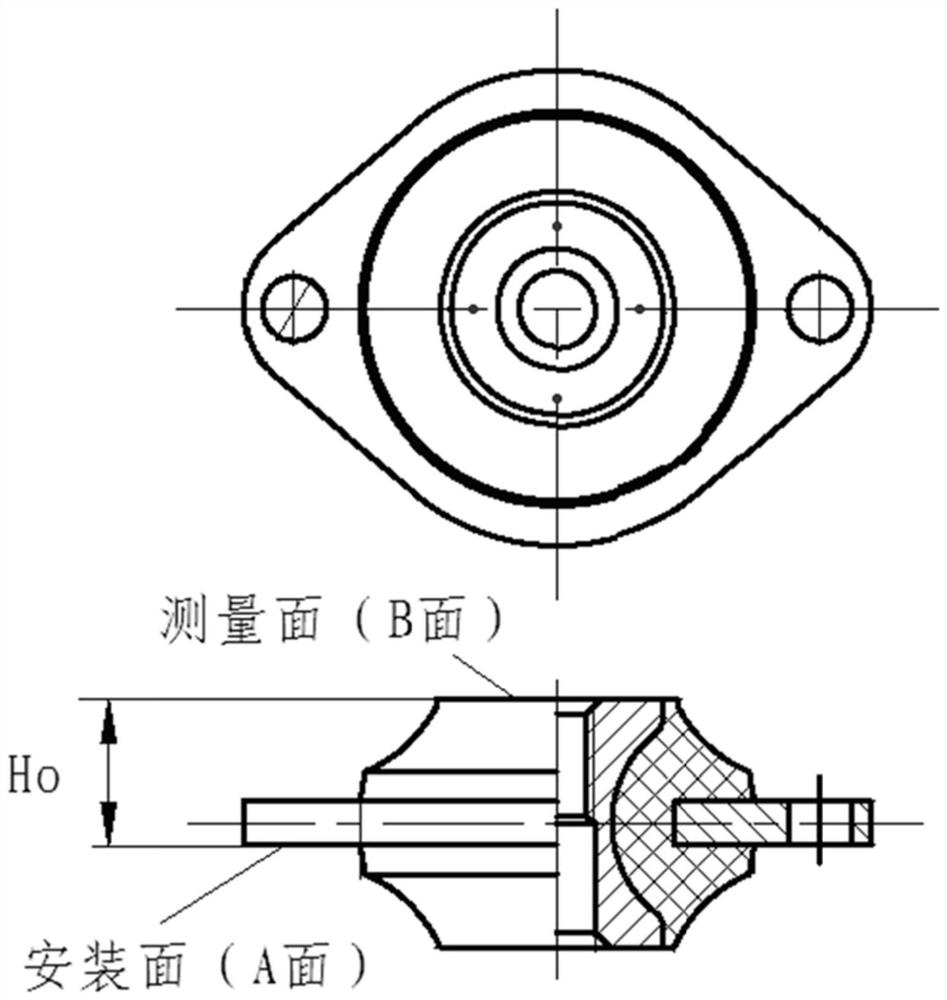

[0033] (2) Install the selected shock absorber on the special tooling, such as figure 2 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com