Self-checking method and device of electromagnetic sensor

A technology of electromagnetic sensors and self-checking devices, which is applied in the field of electromagnetic sensors, can solve the problems of low detection efficiency of distributed electromagnetic sensors, inability to detect and install electromagnetic sensors, and complicated detection process, and achieve convenient detection, low detection efficiency, and simple detection process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Embodiment 1 Multi-axis electromagnetic sensor self-test

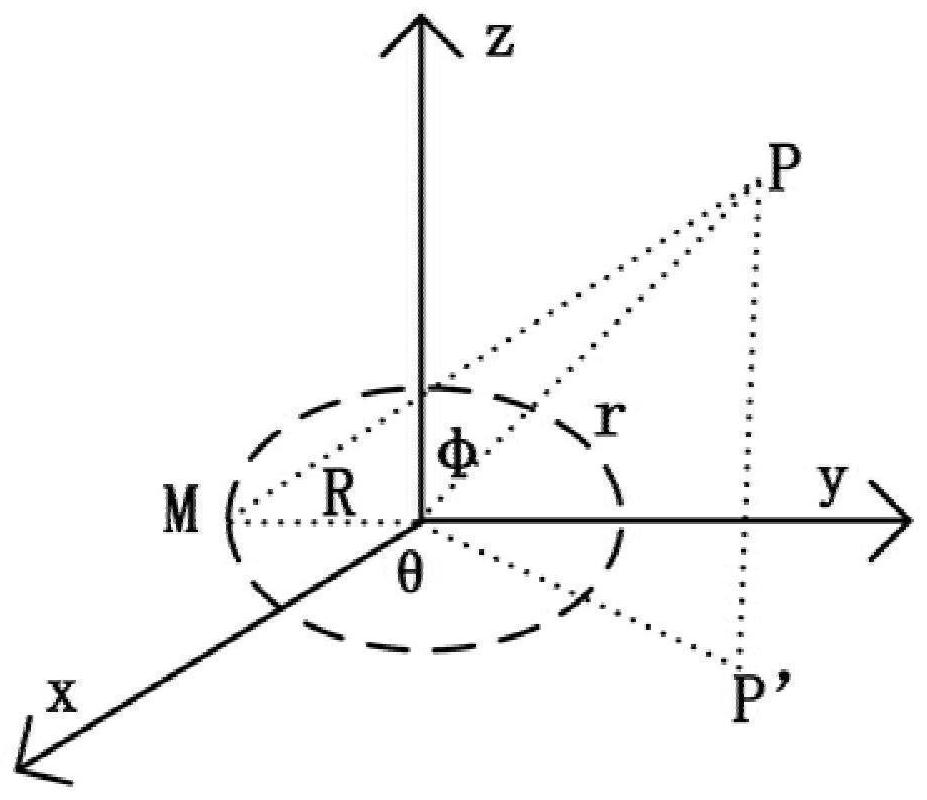

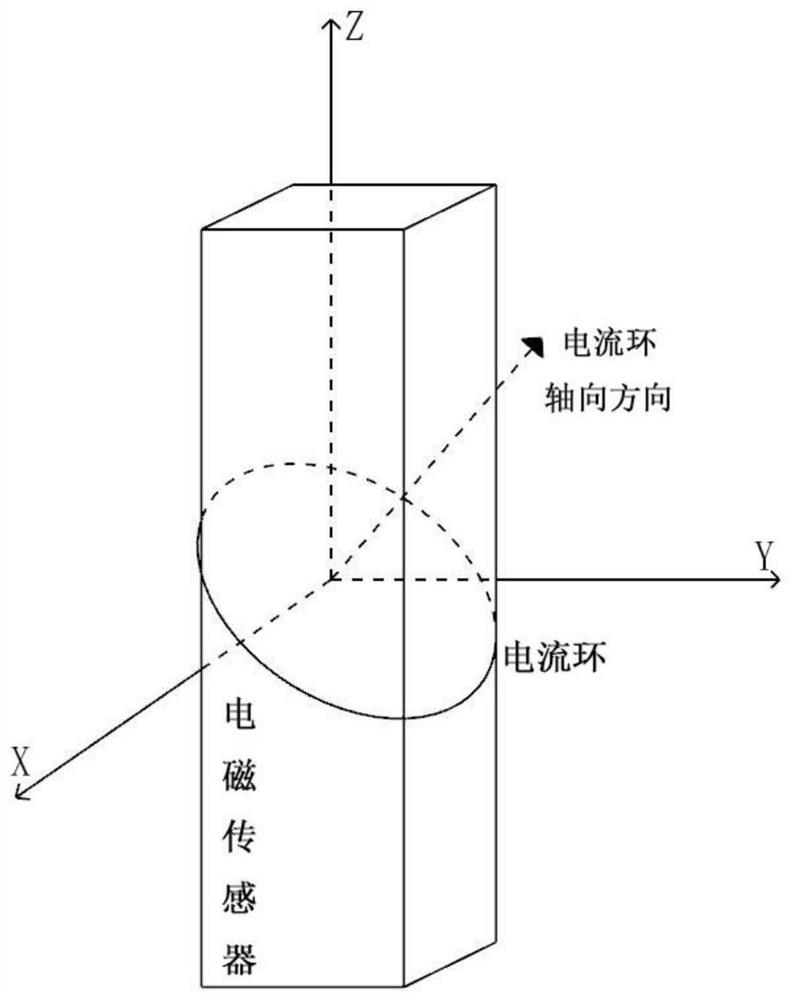

[0074] When the electromagnetic sensor to be detected is a multi-axis electromagnetic sensor scene, the electromagnetic sensor should be placed in the center of the coil, and the coils should be arranged as image 3 In the form shown, the plane where the coil is located is not parallel to the detection sensitive axis of the electromagnetic sensor, so that all axes of the electromagnetic sensor can detect the magnetic field generated by the coil. When the electromagnetic sensor to be tested is an orthogonal three-axis, the ideal coil layout is that the angle between the coil axis and the three coordinate axes should be approximately equal to 54.73°. At this time, when the magnetic field generated by the coil is B, the three-axis detection of the electromagnetic sensor The received magnetic field strength is B / √3, which can make three-axis self-test at the same time. Similarly, when the electromagnetic sensor to ...

Embodiment 2

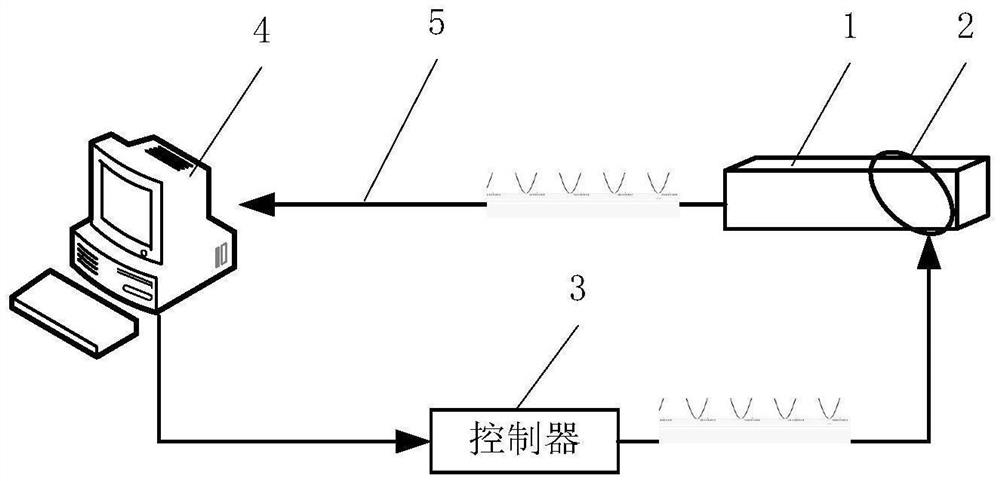

[0075] Embodiment 2 Distributed electromagnetic sensor self-inspection; electromagnetic sensor self-inspection located in a sealed space

[0076] When a plurality of electromagnetic sensors are distributed in different spaces or locations, and are in the distributed electromagnetic sensor self-test; when the electromagnetic sensor is located in a sealed space, the controller 3 and the coil 2 can be integrated with the electromagnetic sensor. When self-inspection is required, the self-inspection can be completed by performing the self-inspection steps S1 to S4.

[0077] It can be seen from the formula that the magnetic field radiated by the energized coil is symmetrical. In order to make each axis of the electromagnetic sensor receive the magnetic field radiated by the coil, it is necessary to adjust the relative position of the electromagnetic sensor and the coil so that each axis of the electromagnetic sensor can receive the magnetic field radiated by the coil. The axis is no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com