In-situ passive temperature measurement method

A temperature measurement, in-situ technology, used in thermometers, measuring devices, measuring heat and other directions, can solve problems such as difficulty in temperature measurement, and achieve the effects of simple structure installation, strong shock resistance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] specific implementation plan

[0030] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

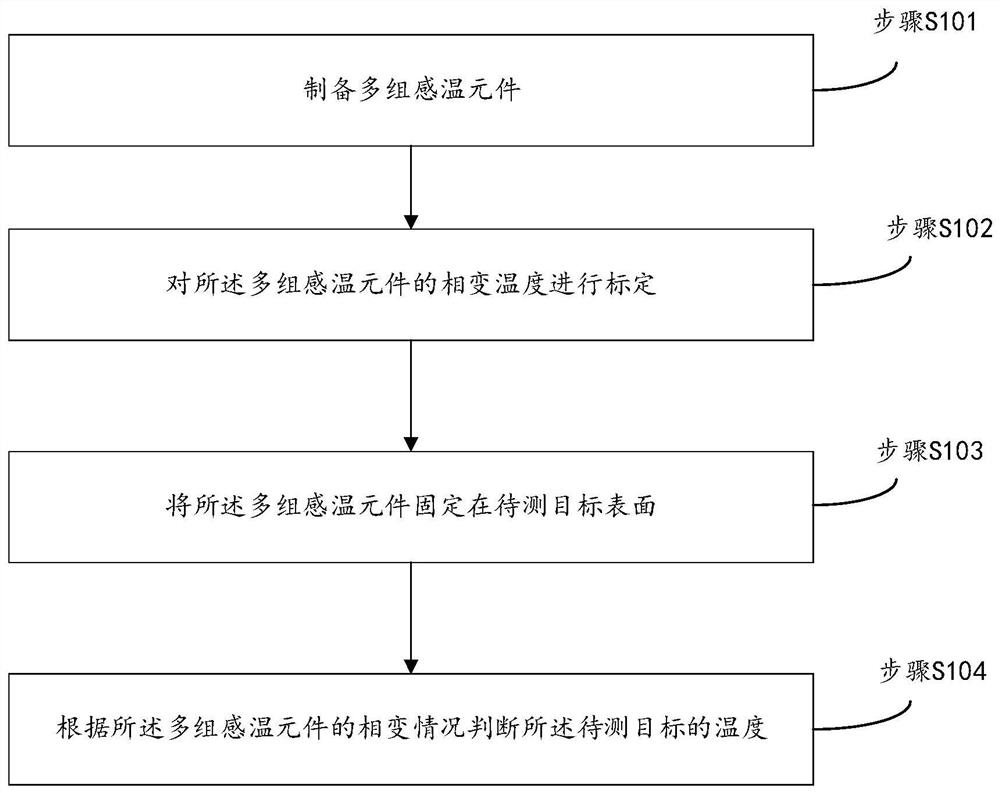

[0031] refer to figure 1 , this embodiment provides an in-situ passive temperature measurement method, including:

[0032] Step S101, preparing multiple sets of temperature sensing elements;

[0033] Step S102, calibrate the phase transition temperature of the plurality of sets of temperature sensing elements;

[0034] Step S103, fixing the plurality of sets of temperature sensing elements on the surface of the target to be measured;

[0035] Step S104 , judging the temperature of the target to be measured according to the phase transitions of the multiple groups of temperature sensing elements.

[0036] Specifically, step S101 is executed to process multiple sets of temperature-sensing materials whose th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com