Product surface defect detection method in industrial scene

A defect detection and industrial technology, applied in neural learning methods, image data processing, instruments, etc., can solve the problems of insufficient detection method accuracy, small defect detection, generalization and robustness, etc., to improve the accuracy , the effect of reducing the amount of design and enhancing the characterization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The following describes several preferred embodiments of the present invention with reference to the accompanying drawings, so as to make the technical content clearer and easier to understand. The present invention can be embodied in many different forms of embodiments, and the protection scope of the present invention is not limited to the embodiments mentioned herein.

[0063] The existing product surface defect detection method in the industrial scene still has the problem that the accuracy of the product surface defect detection method is not high enough, especially the detection of small defects, the generalization and robustness are not strong enough, and how to achieve the speed of product surface defect detection and Accuracy is better trade-off problem.

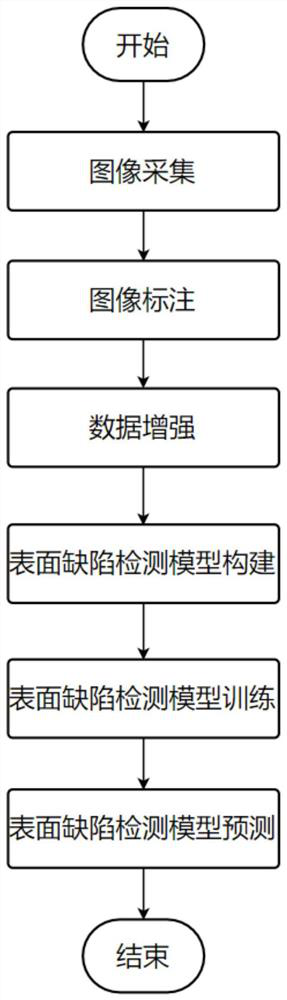

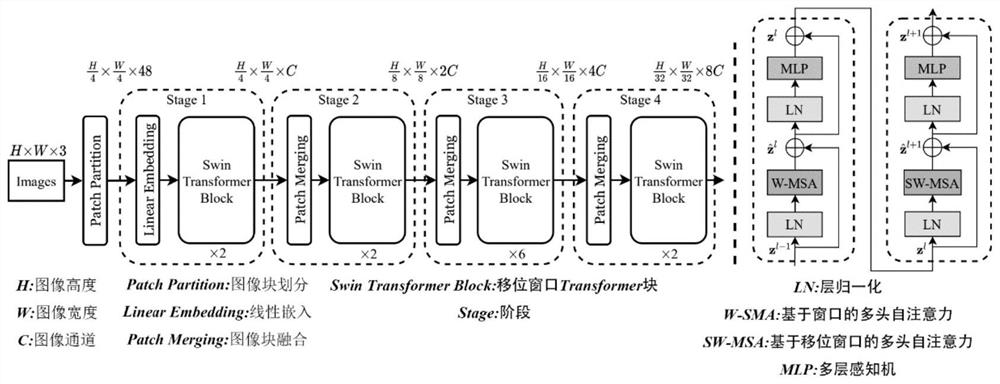

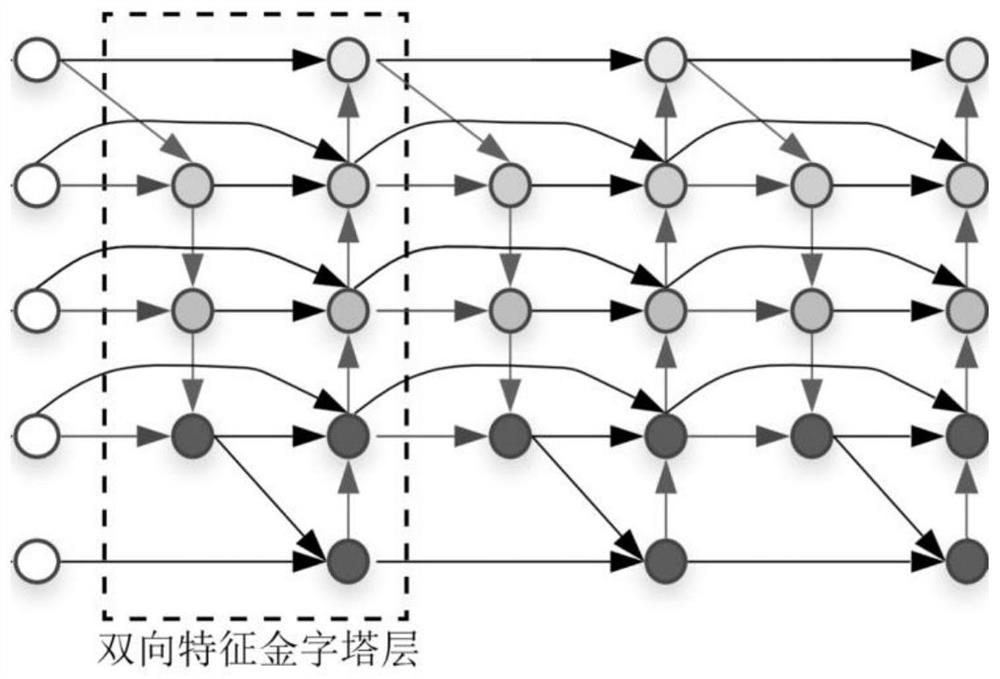

[0064] In an embodiment of the method for detecting product surface defects in an industrial scenario provided by the present invention, improvements are made to the problems existing in the prior art from fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com