Plate part milling device for splicing robot machining

A technology of robot processing and milling devices, which is applied to metal processing machinery parts, feeding devices, metal processing equipment, etc. It can solve the problems that the height of the workbench cannot be adjusted freely, and the milling device has no water recycling device, so as to save physical strength and improve production. Efficiency, water saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

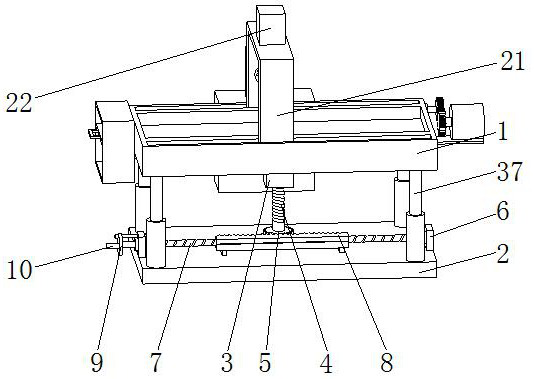

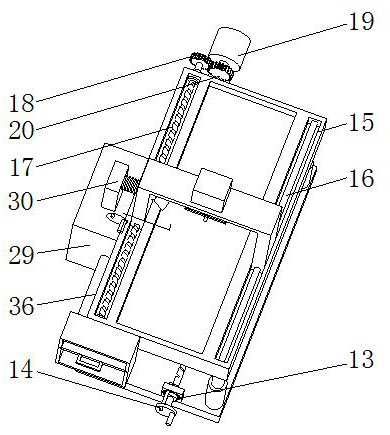

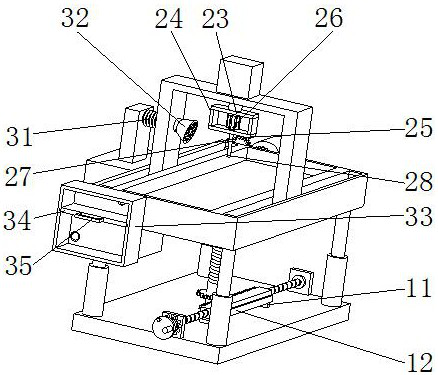

[0025] see Figure 1-3 , the present invention provides the following technical solutions: a splicing robot processing plate parts milling device, comprising a workbench 1 and a bottom plate 2, the bottom of the workbench 1 is fixedly connected with a lifting box 3, and the top of the bottom plate 2 is rotatably connected with a first screw 4. A first gear 5 is fixedly connected to the outer surface of the first screw 4, a support plate 6 is fixedly connected to the top of the bottom plate 2, a second screw 7 is rotatably connected between the support plates 6, and the outer surface of the second screw 7 is threadedly connected There is a toothed plate 8, the toothed plate 8 is meshed and connected with the first gear 5, one end of the second screw 7 extends through and extends to one side of the support plate 6 and is fixedly connected with a rotating wheel 9, and the outer surface of the rotating wheel 9 is fixedly connected with a rotating rod 10.

[0026] In this embodime...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap