Energy-saving air compressor

An air compressor and air cover technology, applied in the field of air compressors, can solve problems such as temperature rise, air compression effects, piston damage, etc., and achieve the effect of avoiding frictional heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

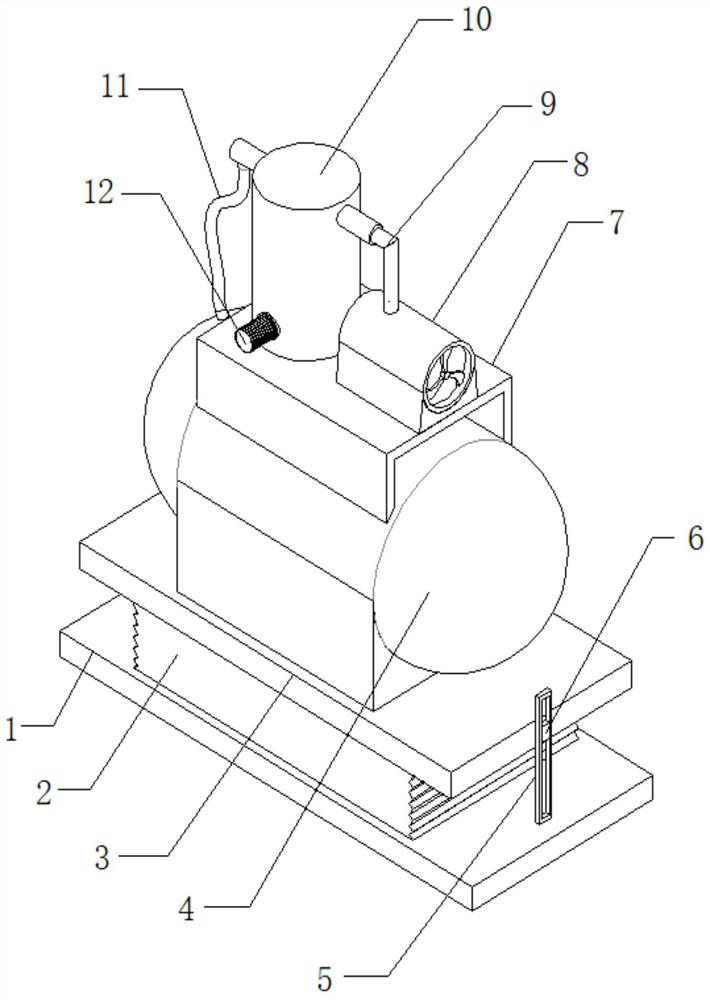

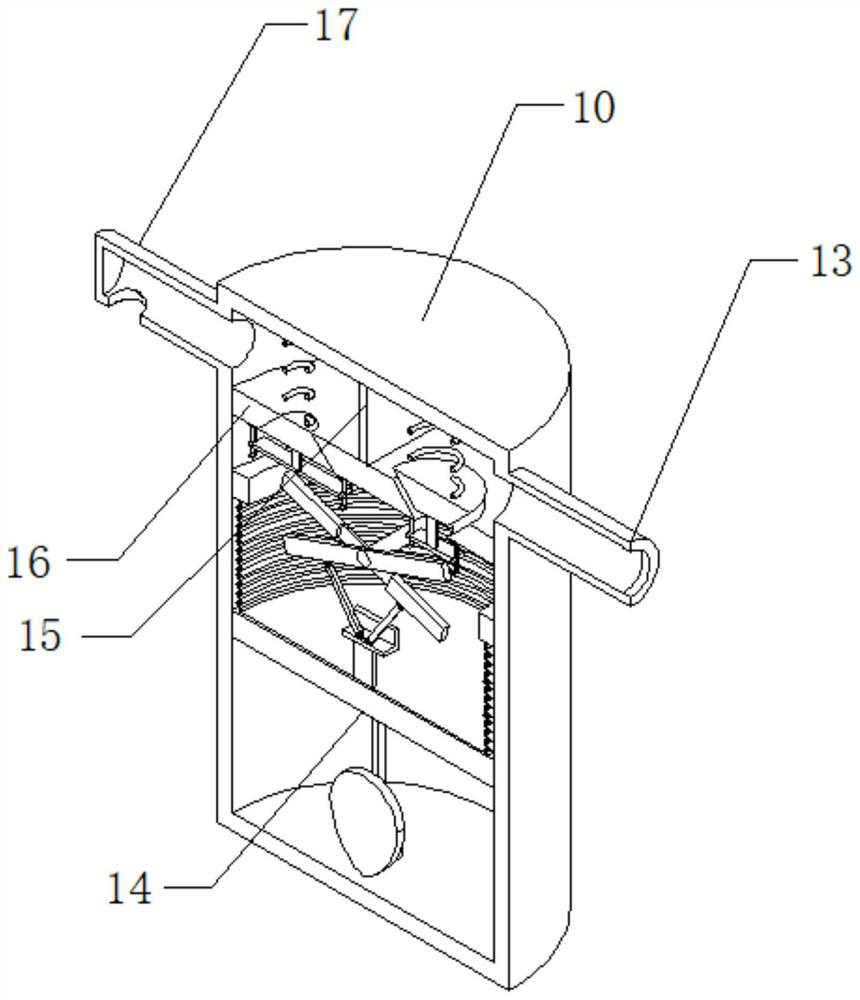

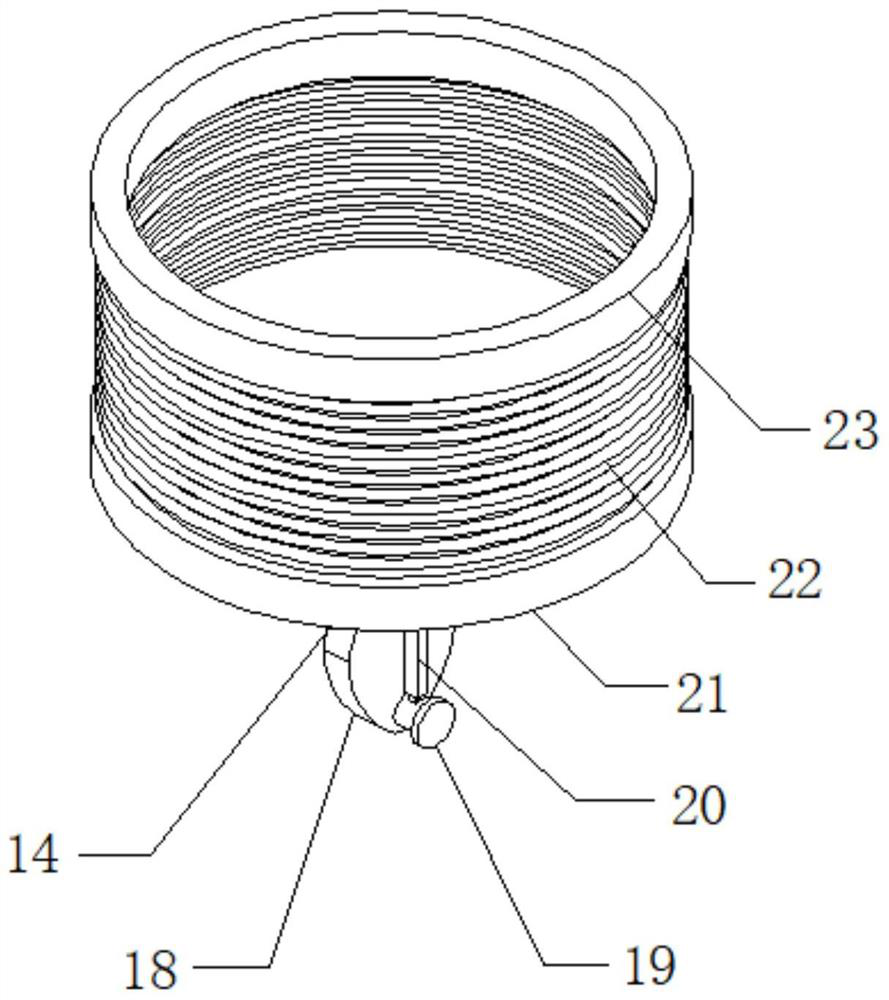

[0027] refer to Figure 1-5 , an energy-saving air compressor, comprising an air storage tank 4, the top outer wall of the air storage tank 4 is connected with a fixed frame 7 by bolts, and the two sides of the top outer wall of the fixed frame 7 are respectively connected with a compression tank 10 and an air pump 8 by bolts, The outer walls of both sides of the compression tank 10 are respectively provided with an air inlet pipe 13 and an exhaust pipe 17, and a connecting pipe 9 is arranged between the air inlet pipe 13 and the air pump 8, and a filtering mechanism 37 is arranged inside the connecting pipe 9, and the exhaust pipe 17 and the storage Conduit 11 is arranged between gas tank 4, and the interior of compression tank 10 is provided with compression mechanism 14, and compression mechanism 14 comprises motor 12, cam 18, support block 21, gas cover 22 and fixed ring 23, and fixed ring 23 and compression tank 10 The inner walls of the cylinders are connected by bolts, ...

Embodiment 2

[0034] refer to figure 1 with Image 6 , an energy-saving air compressor, comprising an air storage tank 4, the top outer wall of the air storage tank 4 is connected with a fixed frame 7 by bolts, and the two sides of the top outer wall of the fixed frame 7 are respectively connected with a compression tank 10 and an air pump 8 by bolts, The outer walls of both sides of the compression tank 10 are respectively provided with an air inlet pipe 13 and an exhaust pipe 17, and a connecting pipe 9 is arranged between the air inlet pipe 13 and the air pump 8, and a filtering mechanism 37 is arranged inside the connecting pipe 9, and the exhaust pipe 17 and the storage Conduit 11 is arranged between gas tank 4, and the interior of compression tank 10 is provided with compression mechanism 14, and compression mechanism 14 comprises motor 12, cam 18, support block 21, gas cover 22 and fixed ring 23, and fixed ring 23 and compression tank 10 The inner walls of the cylinders are connecte...

Embodiment 3

[0037] reference picture figure 1 with Figure 6-8 , an energy-saving air compressor, comprising an air storage tank 4, the top outer wall of the air storage tank 4 is connected with a fixed frame 7 by bolts, and the two sides of the top outer wall of the fixed frame 7 are respectively connected with a compression tank 10 and an air pump 8 by bolts, The outer walls of both sides of the compression tank 10 are respectively provided with an air inlet pipe 13 and an exhaust pipe 17, and a connecting pipe 9 is arranged between the air inlet pipe 13 and the air pump 8, and a filtering mechanism 37 is arranged inside the connecting pipe 9, and the exhaust pipe 17 and the storage Conduit 11 is arranged between gas tank 4, and the interior of compression tank 10 is provided with compression mechanism 14, and compression mechanism 14 comprises motor 12, cam 18, support block 21, gas cover 22 and fixed ring 23, and fixed ring 23 and compression tank 10 The inner walls of the cylinders ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com