Clamp capable of sucking waste liquid

A fixture and waste liquid technology, applied in the direction of manufacturing tools, workpiece clamping devices, cleaning methods and utensils, etc., can solve the problems of easy accumulation of coolant and affect the line of sight, etc., achieve clear sight, improve processing accuracy, and improve use convenience Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

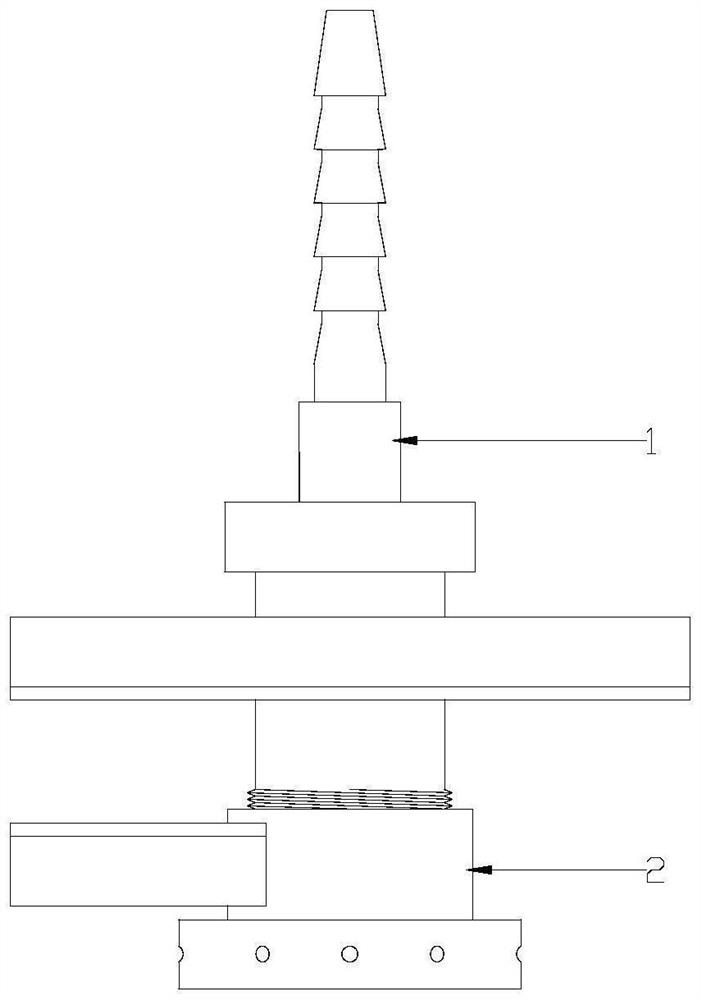

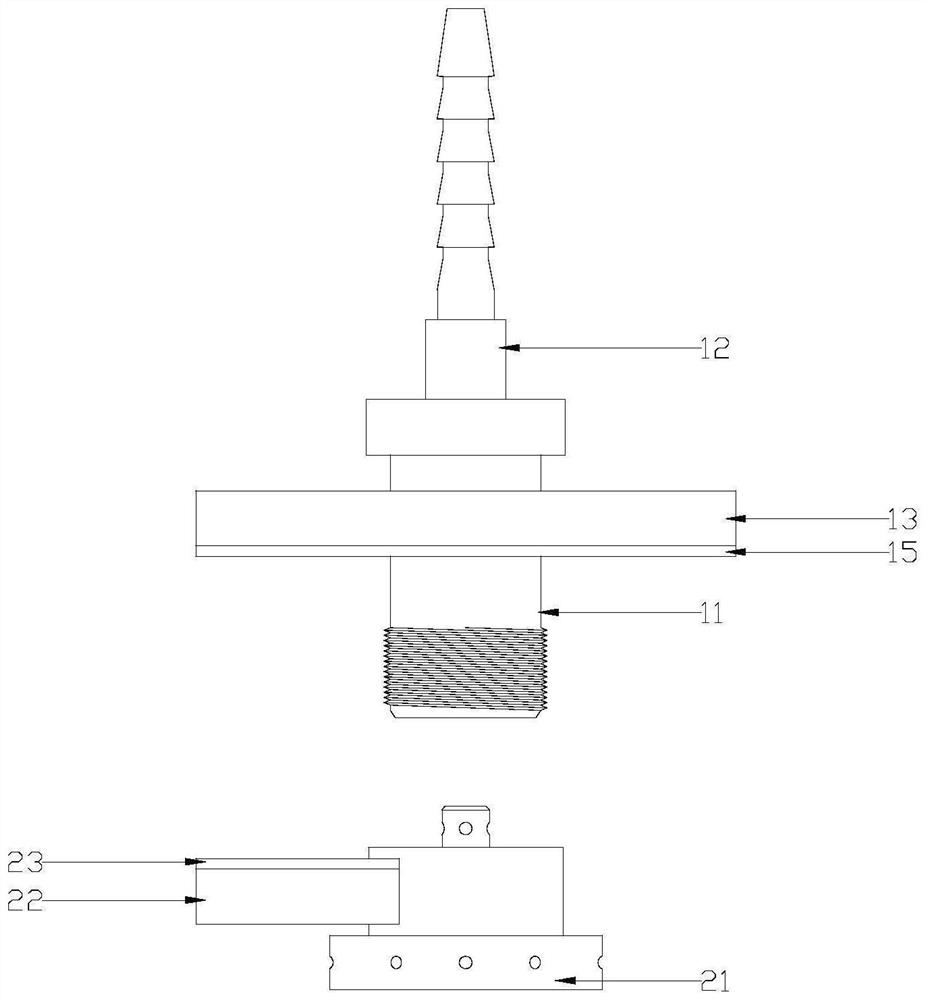

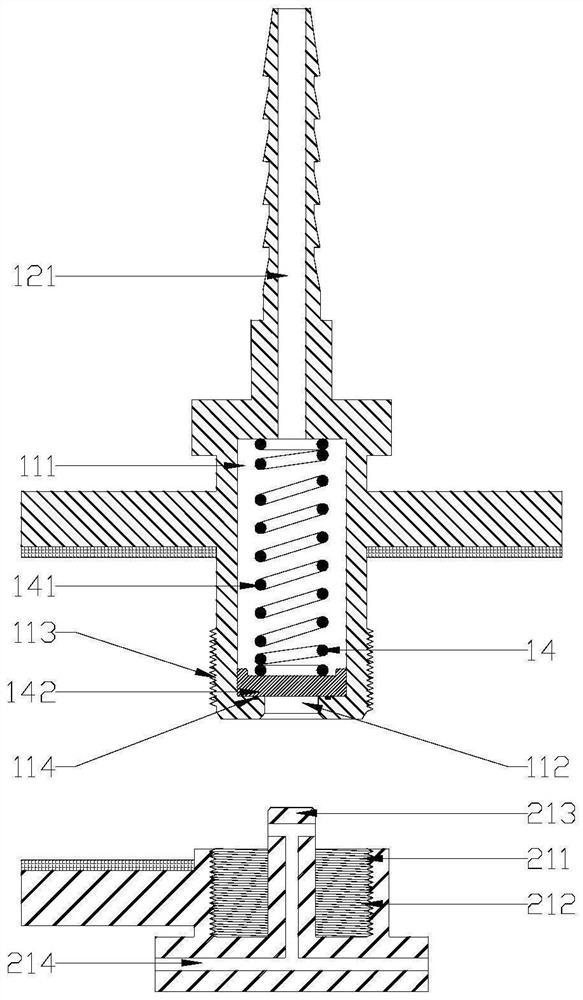

[0021] refer to figure 1 , figure 2 and image 3 , the present invention is a clamp that can suck waste liquid, including a clamp body, a hose, a suction pump and a controller, the clamp body includes a chuck 1 and a base 2, and on the outer walls of the chuck 1 and the base The upper splint 13 and the lower splint 22 are arranged horizontally respectively, the chuck 1 and the base 2 are threadedly connected up and down, and a liquid passage is provided inside, and several inlets of the liquid passage are respectively arranged on the outer wall of the base 2 , the outlet of the liquid passage is connected to a suction pump through a hose, and the suction pump is electrically connected to a controller.

[0022] The chuck 1 includes a main body cylinder 11, a pipe joint 12 and an upper clamping plate 13, the pipe joint 12 is fixed on the top of the main body cylinder 11, and the upper clamping plate 13 is horizontally fixed on the outer wall of the main body cylinder 11. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com