On-site manufacturing and mounting method and manufacturing and mounting equipment for ultra-large cylinder

An on-site production, super-large cylinder technology, applied in the directions of large-scale containers, packaging, transportation and packaging, can solve the problems of large additional stress, increased risk, and easy deformation of components, achieve simple operation, avoid cylinder deformation, resistance, etc. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0035] The on-site production and installation method of the super-large cylinder of the present invention includes

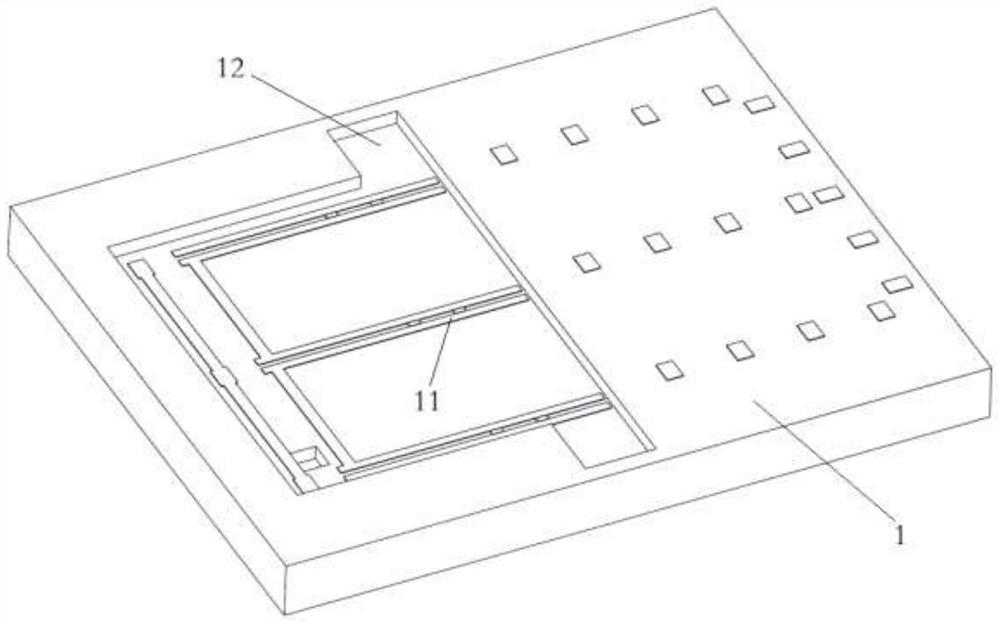

[0036] Manufacture of the ground support 1: the ground support 1 includes an installation part covering the installation location and a manufacturing part outside the installation location, and a plurality of guide rails 11 are installed in the installation part. Such as figure 1 and Figure 4 As shown, the ground support 1 is made of concrete, and is arranged at the installation position of the cylinder body 3, so as to facilitate on-site installation after manufacture at the construction site.

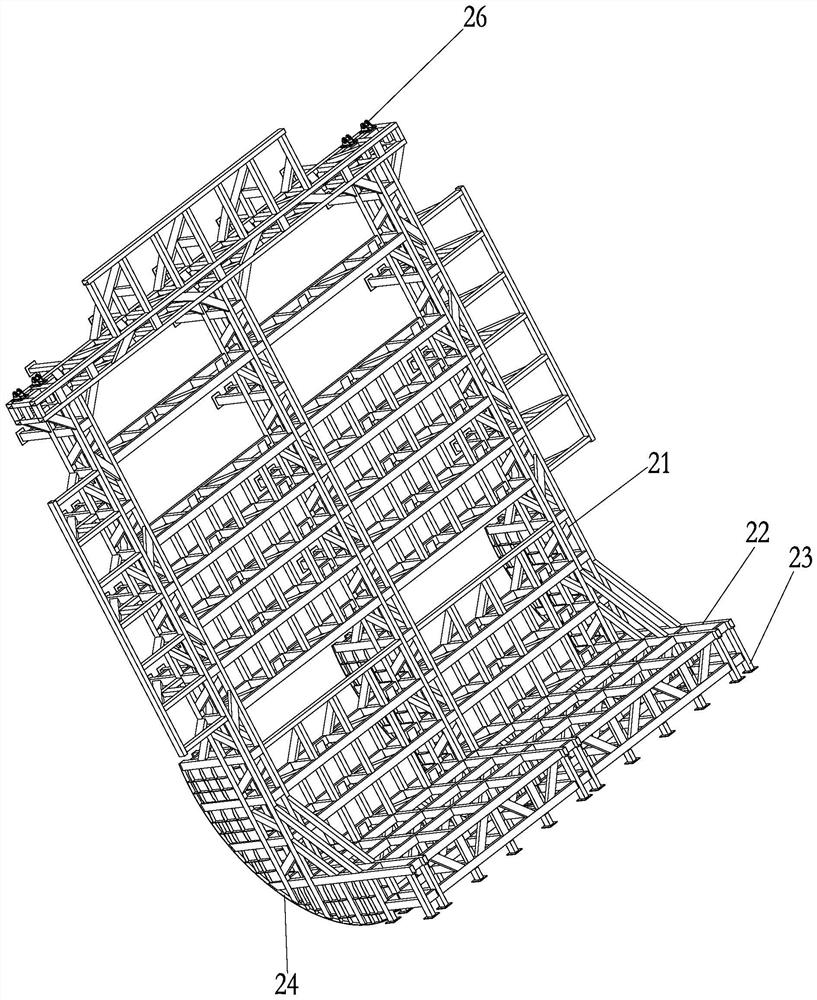

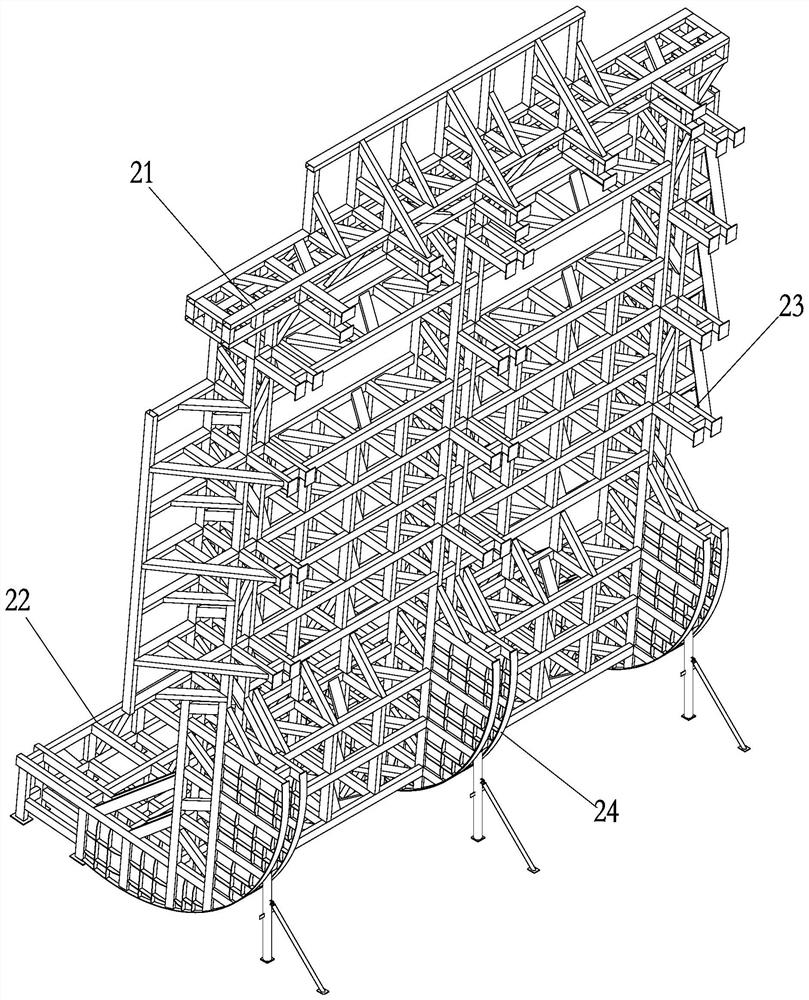

[0037] Make stand-up frame 2: described stand-up frame 2 is formed L shape by manufacturing support frame 21 and installation support frame 22, and the front of installation support frame 22 is provided with arc-shaped frock 25, and the back ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com