Handle structure for portable electric vacuum chuck

A vacuum suction cup, portable technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of unfavorable electrode ventilation and heat dissipation, limited application range, and low dimensional accuracy of finished products, so as to avoid internal water accumulation and increase the application range , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings. In the following description, many specific details are set forth in order to fully understand the application, but the application can also be implemented in other ways different from those described here, therefore, the protection scope of the application is not limited by the specific details disclosed below. EXAMPLE LIMITATIONS.

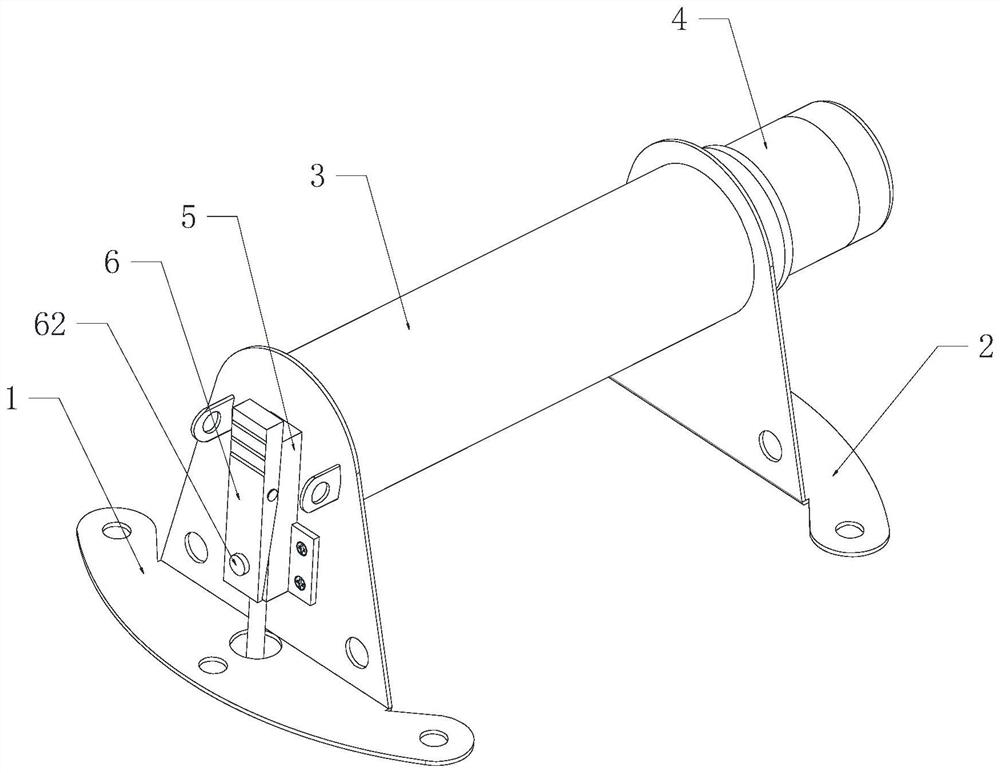

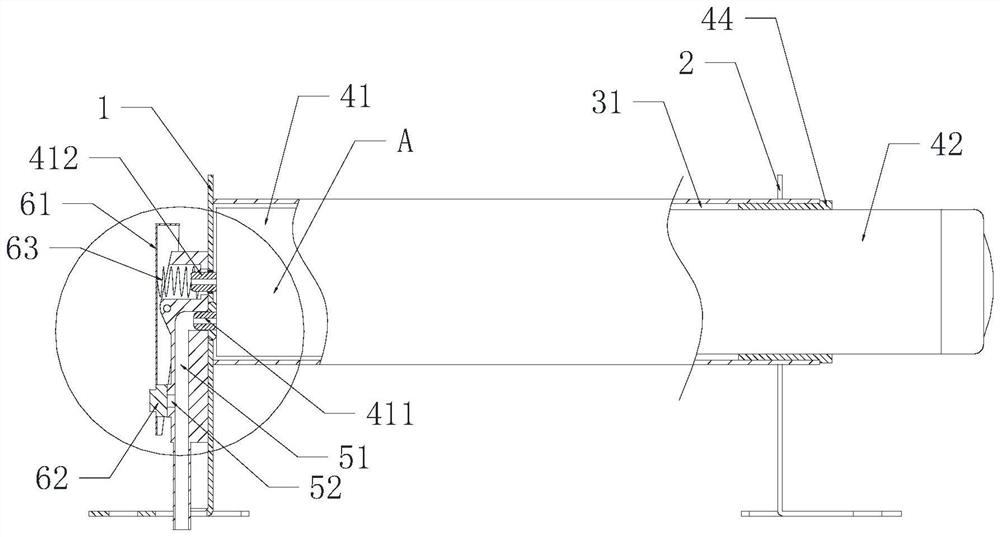

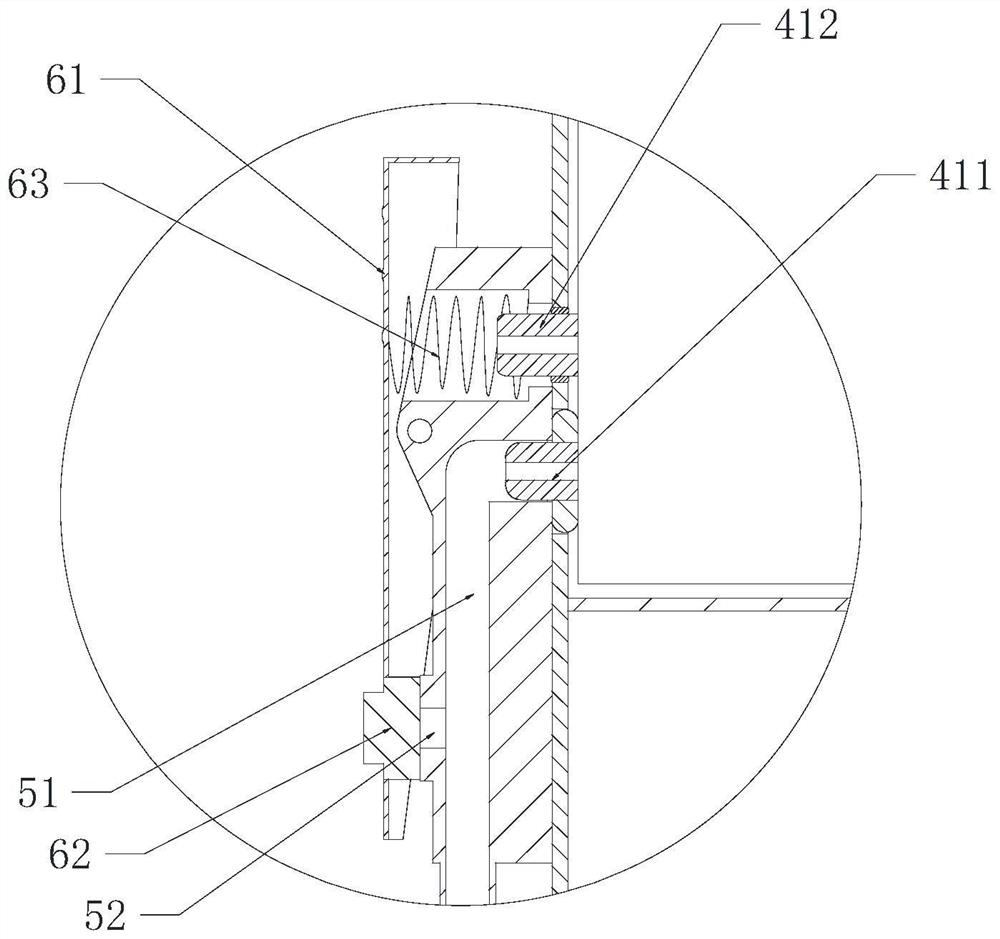

[0052] Such as Figure 1-6 As shown, in this embodiment, the handle structure for the portable electric vacuum chuck includes:

[0053] Front seat 1 and rear seat 2 for fixing with the main body of the suction cup;

[0054] The handle 3 erected on the front seat 1 and the rear seat 2, the handle 3 is formed with an installation channel 31, and the front seat 1 is provided with a panel to block the front end of the installati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com