Automatic winding device

A winding device and automatic technology, applied in the directions of transportation and packaging, transportation of filamentous materials, thin material processing, etc., can solve the problems of inability to meet simultaneous production, waste of cost, poor effect, etc., to improve processing efficiency and processing. The effect of quality, ease of use, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

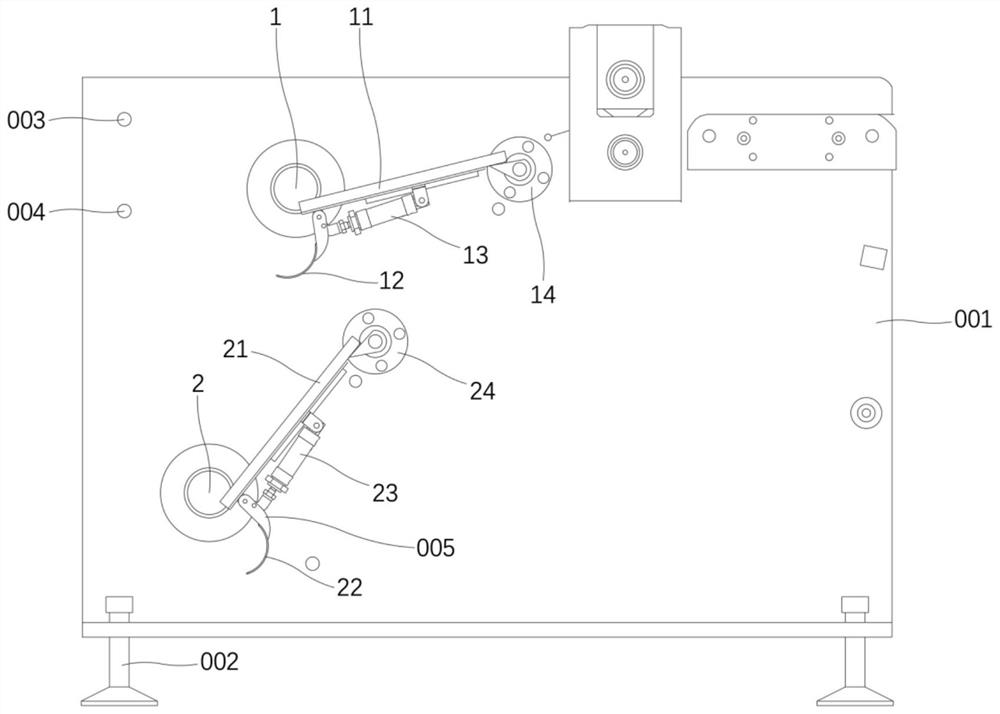

[0023] Such as figure 1 As shown, the present invention provides an automatic winding device, including a device body 001, a support column 002, a first inflatable shaft 1 and a second inflatable shaft 2, wherein the device body 001 is also provided with a first adjusting device 14 And the second adjusting device 24, in the present embodiment, the first adjusting device 14 and the second adjusting device 24 are used to adjust the angle or position of the first conveying plate 11 and the second conveying plate 22;

[0024] The first conveying plate 11 is installed on the first adjusting device 14, wherein, the first pallet 12 is installed on the bottom of the first conveying plate 11, and the second conveying plate 21 is installed on the second adjusting device 24, wherein, the second conveying plate The bottom of 21 is equipped with a second pallet 22, both the first pallet 12 and the second pallet 22 can be lifted (driven by the first cylinder 13 or the second cylinder 23), w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com