Construction method of upper-layer prefabricated vertical component

A technology of vertical components and construction methods, which is applied to the preparation of building components on site, building structures, pillars, etc., and can solve the problem of long construction period of upper prefabricated vertical components 3, the inability to pour concrete in one piece, and the impact on construction speed and other problems, to achieve the effect of convenient and reliable layout and installation, shortening the construction period, and simple and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

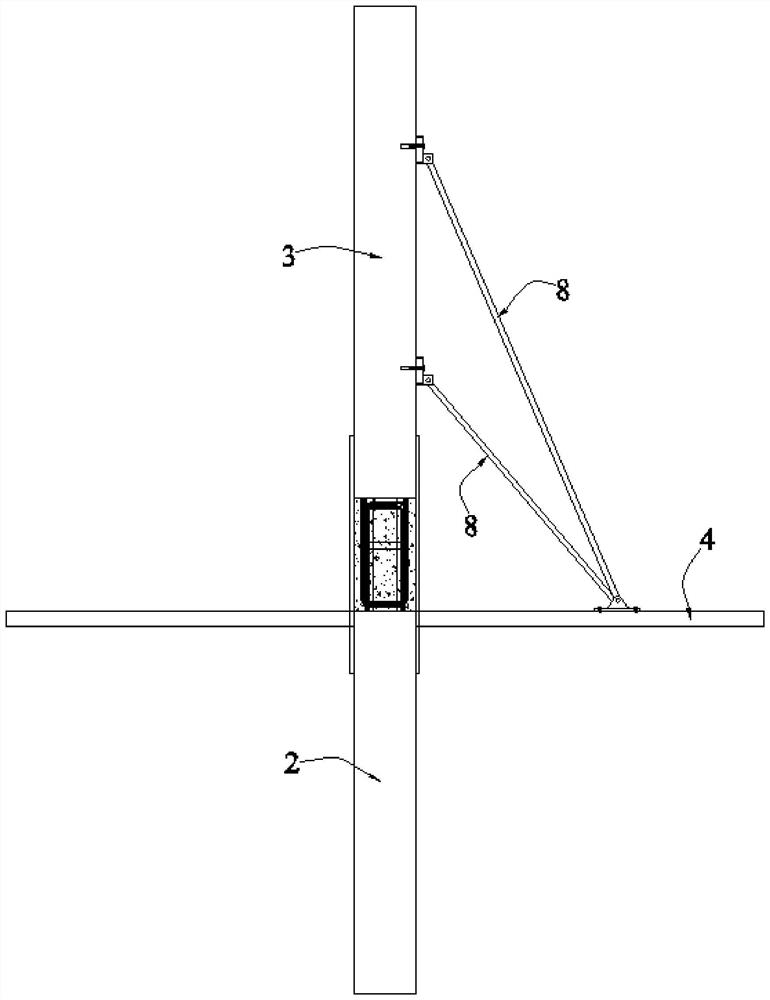

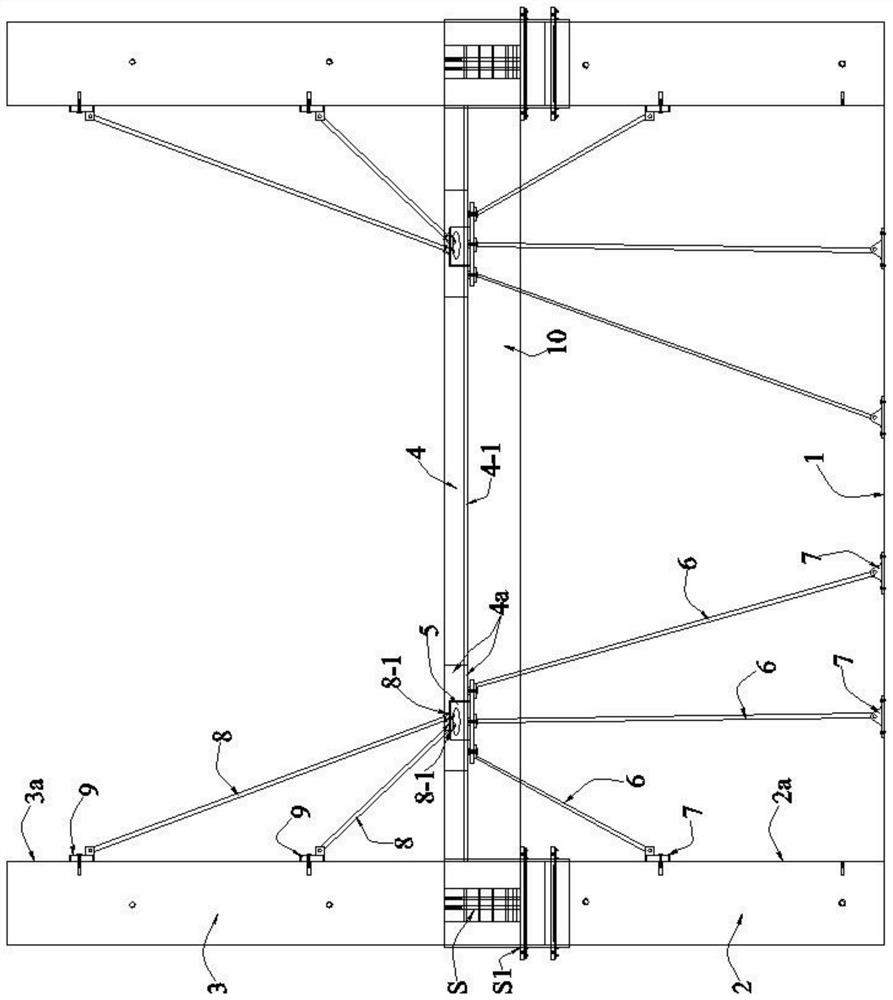

[0041] like figure 2 As shown, what the present invention discloses is a kind of upper layer prefabricated vertical component construction method, comprising:

[0042] Step S1, complete the construction of the lower floor 1 and the lower vertical member 2, and install the reinforcement part of the upper floor 4 and the floor cast-in-place concrete form 4-1, and reserve the reinforcement part and the floor cast-in-place concrete form 4-1 There are a plurality of floor holes 4a; wherein, the upper floor 4 is the upper floor of the lower floor 1, and adopts a cast-in-place floor structure or a floor deck structure;

[0043] Wherein, if the upper floor 4 itself is designed with reserved holes near the upper prefabricated vertical member 3, these reserved holes can be used as the floor holes 4a, if the number of reserved holes near the upper prefabricated vertical member 3 is insufficient , the floor hole 4a can be additionally set, and the floor hole 4a can be filled by pouring ...

Embodiment approach

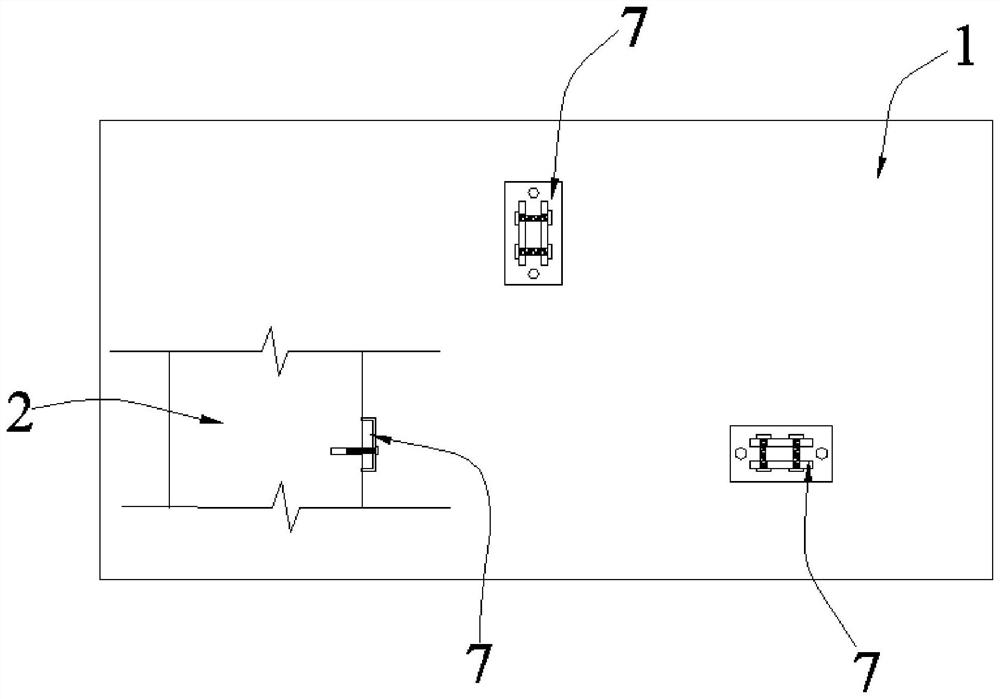

[0062] The lower support structure includes three lower braces 6, one of which is connected between the side 2a of the lower vertical member 2 and the bottom of the support 5, and the other two lower braces 6 are connected between the between the lower floor slab 1 and the bottom of the support member 5, and the three lower struts 6 are not parallel to each other and are not on the same plane, so that the fulcrums of the three lower struts 6 on the horizontal plane are arranged in a triangular orientation, see image 3 , can improve the stability of the underlying support structure.

[0063] The above is the basic implementation mode of the second embodiment, further optimization, improvement and limitation can be done on the basis of the basic implementation mode:

[0064] Preferably: one of the lower braces 6 is perpendicular to the lower floor 1, so that the lower supporting structure can obtain better supporting effect.

[0065] Preferred: see figure 2 and Figure 4 , ...

Embodiment 3

[0067] On the basis of the above-mentioned embodiment 1 or embodiment 2, this embodiment 3 also adopts the following preferred implementation modes:

[0068] The upper support device includes two upper struts 8, both of which are telescopic rods whose length can be adjusted and locked; The mounting seat 9 is fixed on the side surface 3a of the upper prefabricated vertical member 3 by means of bolt connection, the lower end of the upper strut 8 is provided with a buckle 8-1 that can be opened and closed, and the support member 5 is provided with Evacuation hole 5a, to form buckle lock side 5-1 on the top of described support member 5, described buckle ring 8-1 is fastened on this buckle lock side 5-1; And, described two upper struts 8 The corresponding two upper mounts 9 are on the same vertical line. Therefore, the upper prefabricated vertical member 3 can be stably supported obliquely by the two upper struts 8 .

[0069] The above is the basic implementation of the third em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com