Integrated detachable assembly type T-shaped die wall and mounting method

A prefabricated and integrated technology, applied in the processing of walls, building materials, building components, etc., can solve the problems that affect the beauty of the wall, the integrity of the wall, the inconvenience of quick installation and disassembly, and the large amount of labor and time spent. , achieve high and low temperature resistance, improve stability, and reduce the effect of loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

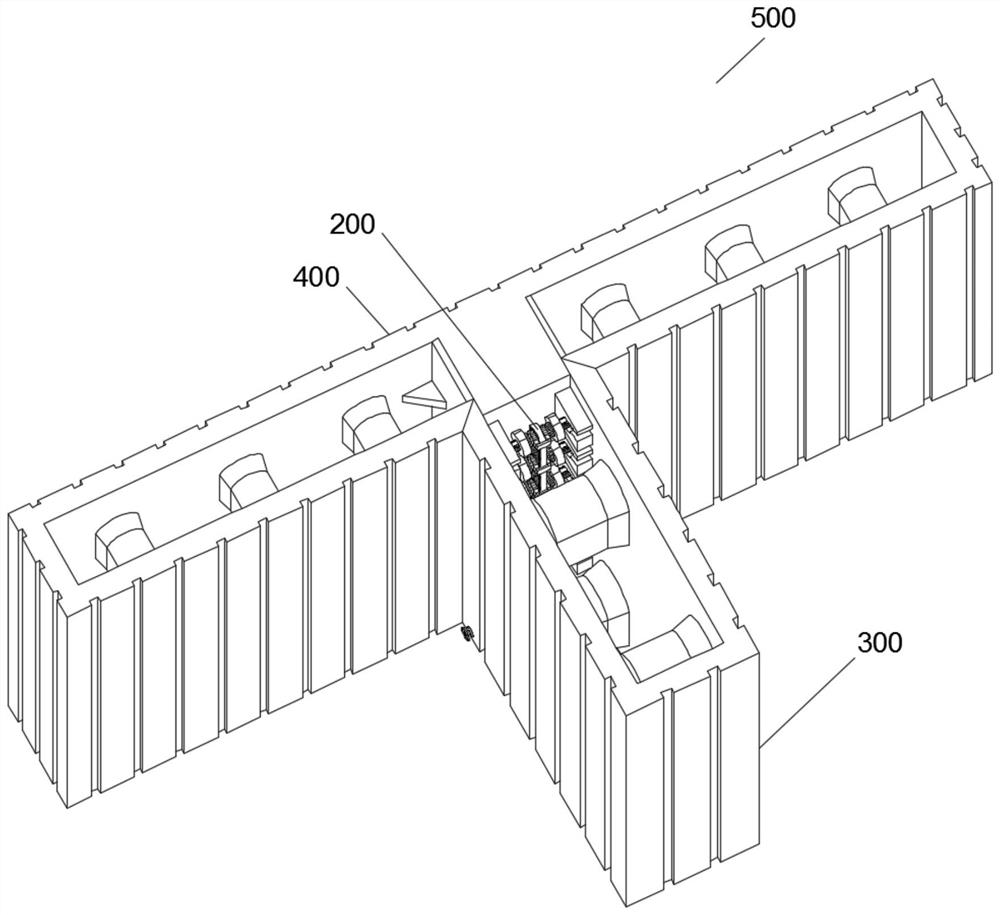

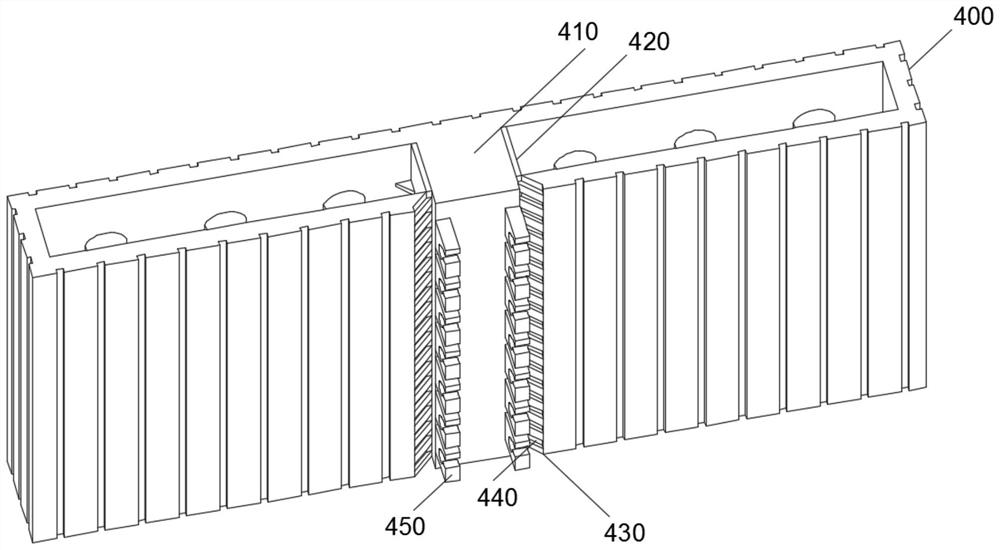

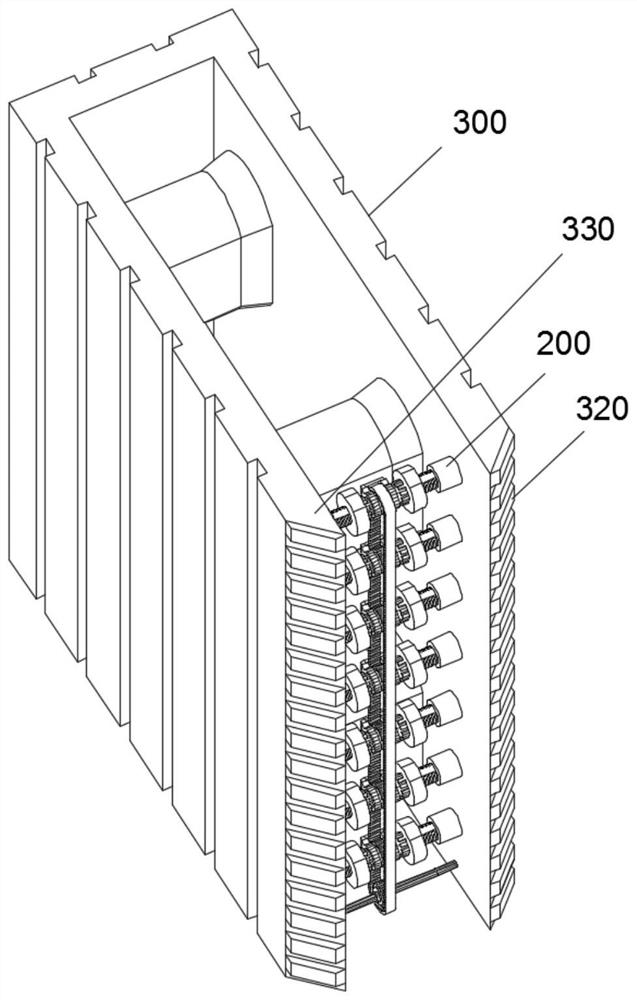

[0034] Refer to attached Figure 1-9 , the present invention provides an integrated detachable assembled T-form wall and its installation method. , including T-shaped wall 500, wall one 400, wall two 300, installation device 200 and locking device 100, T-shaped wall 500 includes wall one 400 and wall two 300 installed vertically to each other, wall one A center plate 410 is installed on the inner wall of 400, and one side of the center plate 410 is fixedly connected with a right-angle reinforcement plate 420. A triangular notch 430 is provided on the outer surface of the front end of the wall body 400, and a slot 440 is provided on the outer surface of the triangula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com