Air leakage valve capable of reducing noise and fatigue damage

A leakage valve and fatigue technology, applied in diaphragm valves, balance valves, valve devices, etc., can solve problems such as easy noise, elastic support fatigue damage, etc., and achieve the effect of prolonging service life and reducing fatigue damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

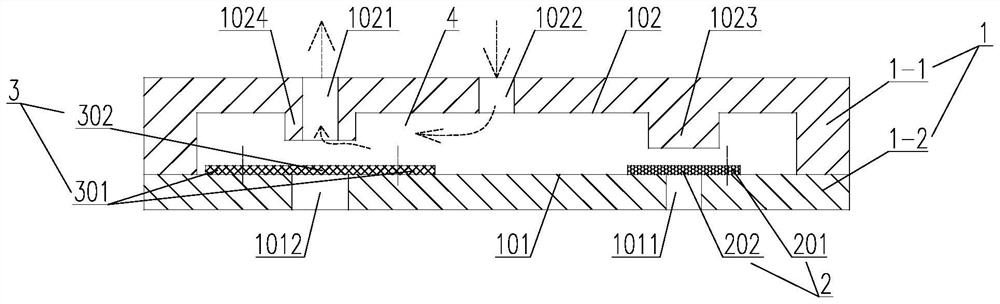

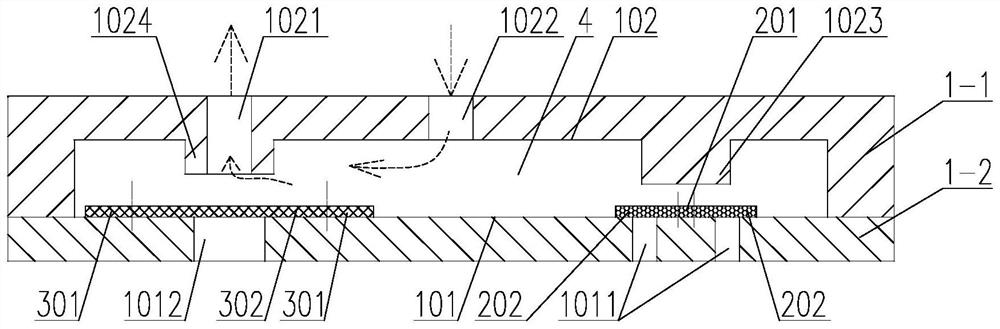

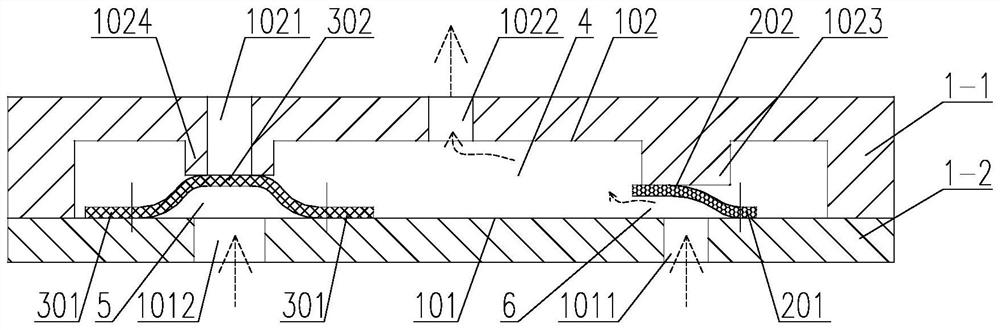

[0057] like Figure 1-9 As shown, a leak valve for reducing noise and fatigue damage includes a diaphragm structure and a valve housing 1 with an inner cavity. The intake side 101 has at least one first air hole 1011 and at least one second air hole 1012. The valve housing 1 can be a spliced structure. The valve housing 1 used in this embodiment specifically includes a stacked upper valve cover 1-1 and Lower bonnet 1-2, an inner cavity is formed between the upper bonnet 1-1 and the lower bonnet 1-2, the inner side wall of the upper bonnet 1-1 is the side wall of the gas outlet side 101 of the inner cavity, and the lower bonnet 1 The inner wall of -2 is the side wall of the intake side 102 of the inner cavity;

[0058] The diaphragm structure includes a diaphragm 3 and an intermediate valve plate 2, and the diaphragm 3 and the intermediate valve plate 2 are arranged separately;

[0059] Regarding the installation and structure of the diaphragm 3:

[0060] The diaphragm 3 i...

Embodiment 2

[0080] like Figure 10-16 As shown, the structure of the leakage valve in this embodiment is basically the same as that in Embodiment 1, the difference is that the connection part 201 includes a first connection part 2011 and a second connection part 2012, and the first connection part 2011 and the inner The side wall of the inlet side 101 of the cavity is fixedly connected, and the valve body 202 is connected to the first connecting part 2011 through the second connecting part 2012, and at least one hole 2012a or groove 2012b penetrates through the second connecting part 2012.

[0081] Preferably, the cross-sectional shape of the hole portion 2012a or the groove portion 2012b may be circular, rectangular, polygonal, etc., which is not limited here.

[0082] The first connecting part 2011 and the second connecting part 2012 are integrally formed or fixedly connected, and the second connecting part 2012 and the valve body 202 can be integrally formed or fixedly connected; prefe...

Embodiment 3

[0093] like Figure 16-18 As shown, the leakage valve in this embodiment is basically the same in structure as the leakage valves in Embodiments 1 and 2, the difference is that the diaphragm 3 and the middle valve plate 2 are integrally formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com