Auxiliary heat dissipation structure, air conditioner and control method

A technology for assisting heat dissipation and control methods, which is applied in heating and ventilation control systems, heating methods, air conditioning systems, etc. performance, avoid wasting power, and ensure the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

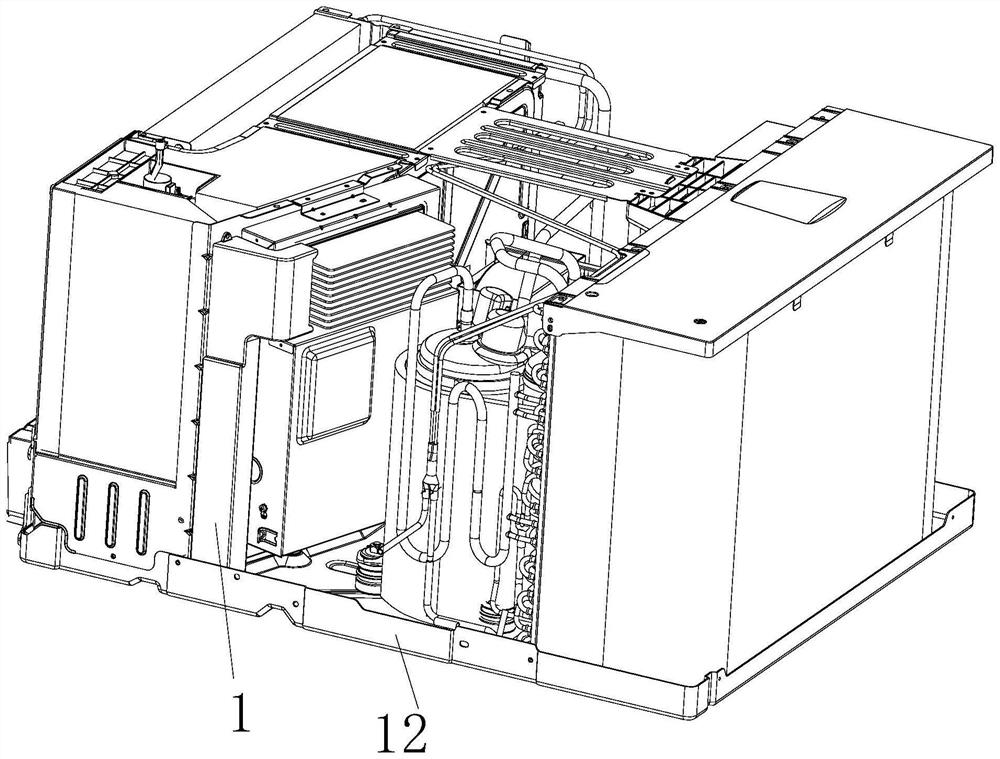

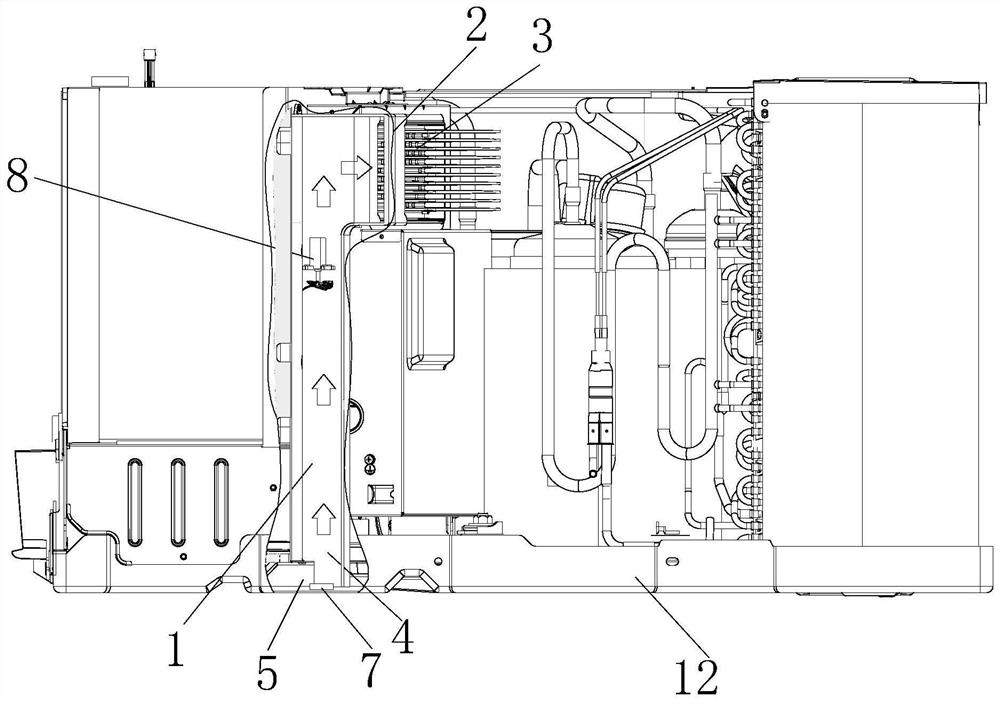

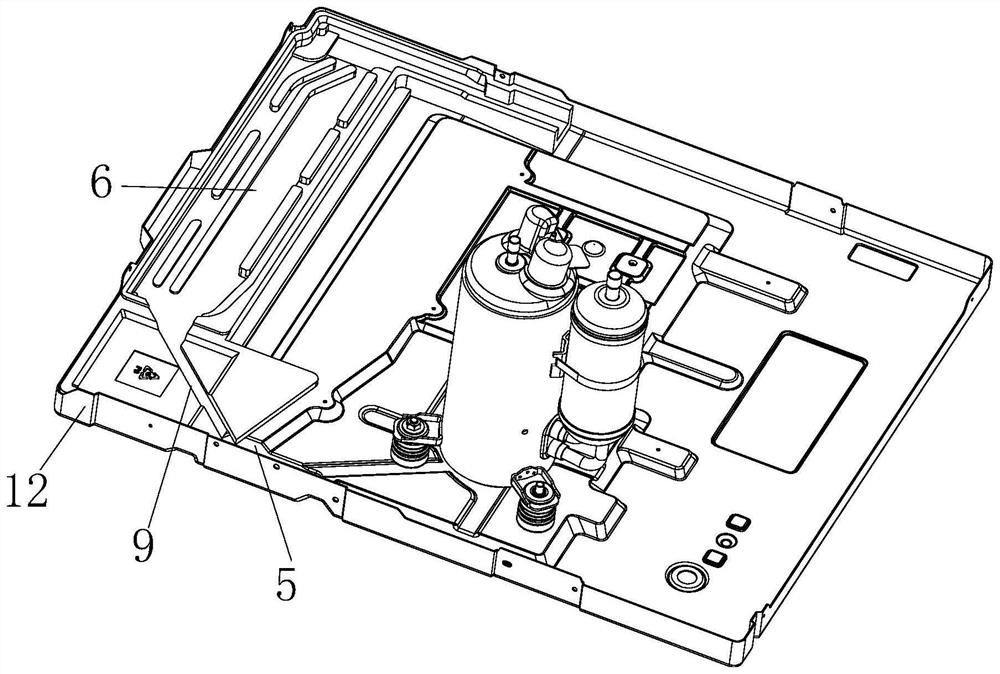

[0038] The auxiliary heat dissipation structure disclosed in this embodiment, figure 1 shown, including the air duct 1 located inside the air conditioner, figure 2 As shown, the air outlet 2 of the air guide duct 1 points to the element to be dissipated 3, and the air inlet 4 of the air guide duct 1 points to the water collecting tank 5, and the water collecting tank 5 is connected to the water receiving tray 6 of the condensed water of the evaporator, figure 2 As shown, the water collecting tank 5 is provided with an atomizer 7, the air guide 1 is provided with an induced draft fan 8, and the exhaust port of the induced draft fan 8 is located at the air outlet 2-1 of the air guide 1 side.

[0039] An induced draft fan 8 is arranged in the air guide duct 1, and the air guide duct 1 can blow the wind generated by the induced draft fan 8 to the surface of the element 3 to be radiated to assist heat dissipation; After the condensed water is atomized, the condensed water is le...

Embodiment 2

[0048] This embodiment discloses an air conditioner, which includes the auxiliary heat dissipation structure of Embodiment 1.

Embodiment 3

[0050] This embodiment discloses the control method of the auxiliary heat dissipation structure in embodiment 1, and the control method includes the following steps,

[0051] S1, detecting the surface temperature T1 of the element 3 to be dissipated,

[0052] S2. When T1≥Ta, start the induced draft fan 8 and detect the water level of the sump 5, if the water level of the sump 5 is lower than the protection value, the atomizer 7 will not start, otherwise start the mist at the same time Converter 7; if T1<Ta, then do not start the auxiliary cooling structure;

[0053] Wherein, when the induced draft fan 8 is turned on, continue to detect the surface temperature T2 of the element 3 to be dissipated, and if T2≥Tb, increase the speed of the induced draft fan 8 , otherwise keep the speed of the induced draft fan 8 .

[0054] Wherein, the surface temperature of the heat dissipation element is detected continuously to obtain T1 and T2 respectively. Continuous detection of the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com