Stepped spiral baffle plate air preheater

A technology of spiral baffles and air preheaters, applied to indirect heat exchangers, heat exchanger types, heat exchanger shells, etc., can solve the problems of large pressure drop on the shell side, high cost, and difficult assembly, and achieve Effect of improving service life and reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

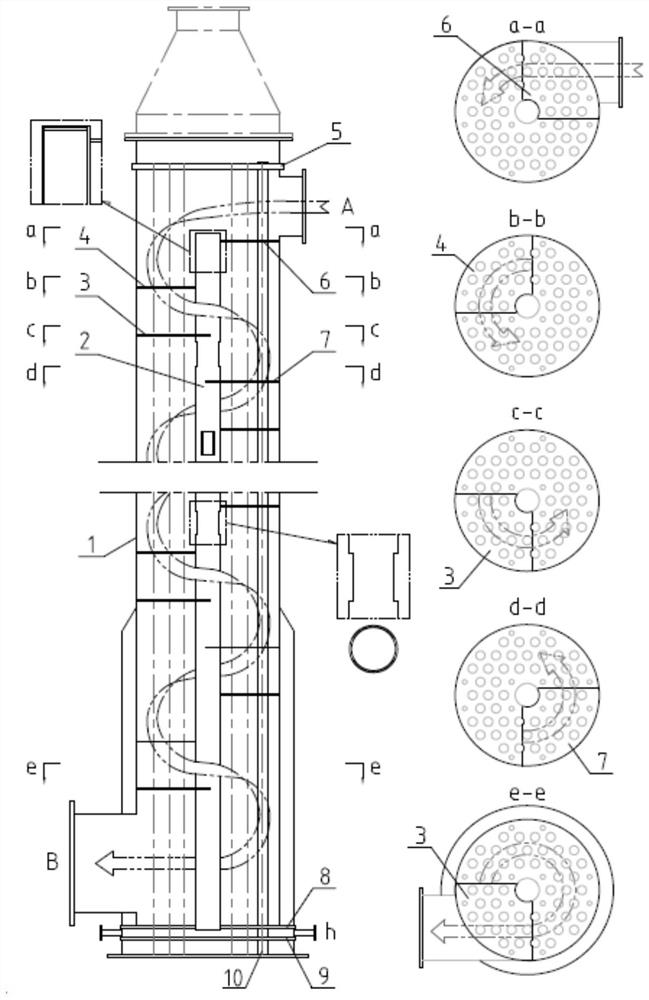

[0020] Step-type spiral baffle air preheater, including: shell 1, central tube 2, baffle III3, baffle II4, upper tube plate 5, baffle I6, baffle IV9, lower tube plate I8 , Lower tube plate II 9, heat exchange tube 10.

[0021] The specific implementation process:

[0022] 1. Manufacture of baffles: the projected area of each baffle is greater than 1 / 4 projected area of the inner diameter of shell 1, and the quantity is according to the design requirements;

[0023] 2. The center tube is made: the diameter of the center tube 2 is larger than the diameter of the heat exchange tube, and the length is from the lower tube plate I8 to the first baffle plate I6 at the cold air inlet A. The center tube 2 is opened according to the size and position given by the design For the tuyere, seal the top outlet with a blocking plate;

[0024] 3. Tube plate processing: the diameter of the opening in the middle of the lower tube plate Ⅰ8 is slightly larger than the outer diameter of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com