Manufacturing method of sintered and melted 980-1550nm optical isolator

A manufacturing method and optical isolator technology, applied in the field of communication, can solve the problems of inability to effectively meet the use requirements, the difficulty of optical fiber coupling, and the poor anti-interference effect, so as to improve the anti-interference ability, the coupling difficulty is small, and the optical loss is small. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

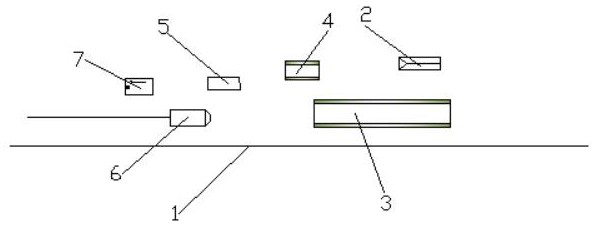

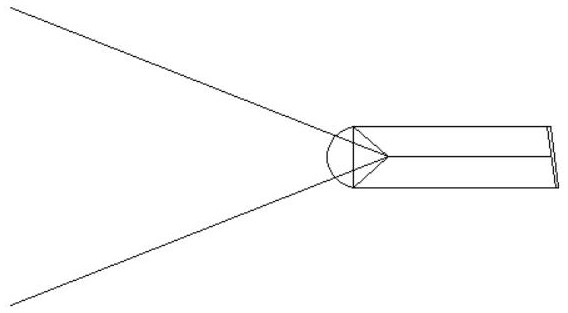

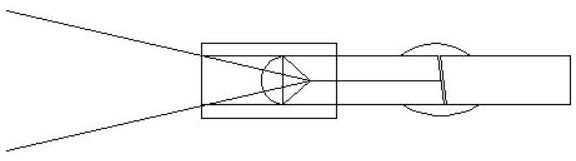

[0013] A method for manufacturing a sintered fusion 980-1550nm optical isolator, comprising the following steps: S1, preparing materials, such as figure 1 As shown, prepare Corning HI1060nm optical fiber, double-hole glass capillary, large glass tube, small glass tube, 0.25 intercept gradient index lens, single-fiber collimator and 1550nm polarization-independent isolator, wherein one side of the lens is a plane and the other side The plane is coated with a film system that transmits 1550nm and reflects 980nm. The inclination angle of the slope is 8° and is coated with a 980 / 1550nm anti-reflection film system; The optical aperture changes from 6um before sintering to 9um at the sintering point after sintering. This step is very critical. The clear aperture becomes 9um at the sintering point, which greatly reduces the difficulty of coupling; S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com