Multi-leg collaborative stowage optimization method

An optimization method and technology of flight segments, applied in the field of shipping stowage, can solve problems such as unsatisfactory high efficiency, large center of gravity deviation, lack of multi-segment collaborative stowage algorithms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

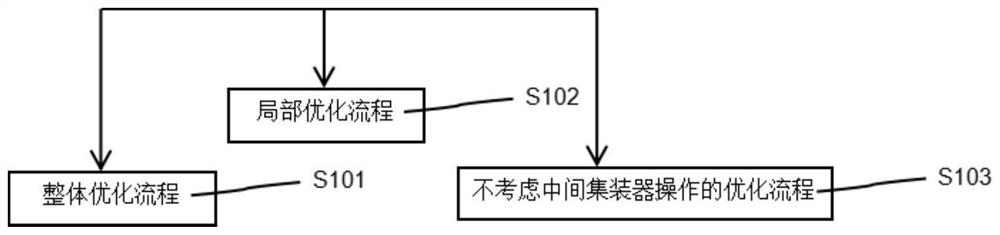

[0216] Example: such as figure 1 , 2 As shown, a multi-segment collaborative stowage optimization method, including:

[0217] A multi-segment collaborative stowage optimization method, characterized in that, comprising:

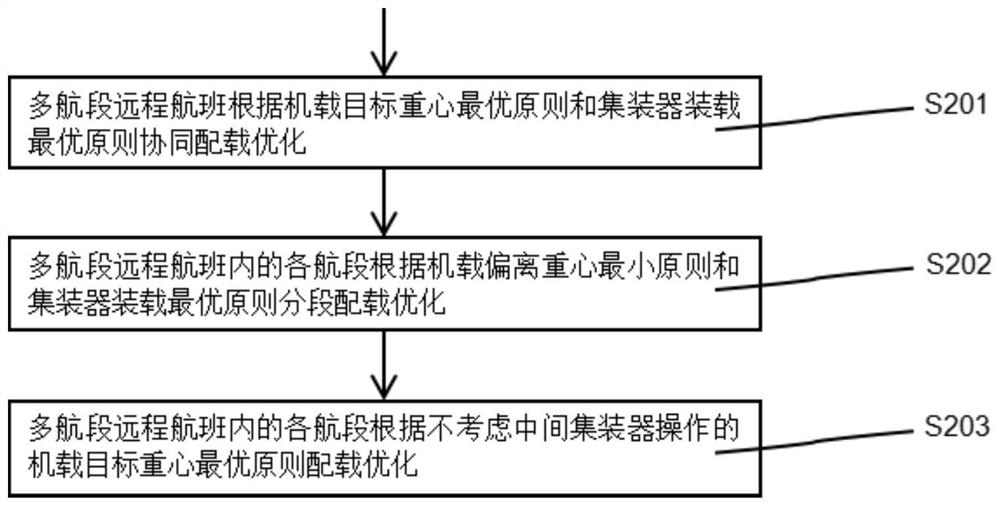

[0218] Overall optimization process S101: Multi-segment long-distance flight is based on the principle of optimal airborne target center of gravity and ULD loading optimization principle S201;

[0219] Local optimization process S102: S202 segmental stowage optimization for each flight segment in a multi-segment long-distance flight according to the principle of minimum airborne deviation from the center of gravity and the principle of optimal container loading;

[0220] Optimization process without considering the operation of intermediate ULDs S103: each flight segment in a multi-segment long-distance flight is loaded according to the principle of optimal airborne target center of gravity without considering the operation of intermediate ULDs S203.

[0...

Embodiment 1

[0624] The solution of the present invention also includes: inputting the target center of gravity CGtarget into the integer programming model, using a new generation of commercial solver Gurobi to solve the model to obtain the target loading solution.

[0625] Specific steps include:

[0626] (1) coding the integer programming model;

[0627] (2) Input the target center of gravity CGtarget;

[0628] (3) call the solver to solve;

[0629] (4) Outputting the loading information.

[0630] Specifically, the Gurobi solver can be called through Python to solve the problem.

[0631] In order to further illustrate the method of this application, take the Boeing B757-200F model of a domestic airline as an example, and select 20 optional ULDs and 200 bulk cargoes to load the aircraft;

[0632] By getting as Figure 13 , 14 The weight W of the ULD shown and the weight w of the bulk cargo are used to obtain the available position j of the aircraft; Figure 10 , 11 , the model dat...

Embodiment 2

[0640] Concrete technical scheme of the present invention is as follows:

[0641] S1: Obtain the weight and quantity information of direct and interline ULDs and the weight and quantity of bulk cargo;

[0642] S2: Select the research model and obtain model data at the same time. The model data is mainly stowage-related data including the original center of gravity envelope, cargo compartment layout, basic parameters such as take-off weight, fuel-free weight and landing weight, etc.;

[0643] S3: Acquiring the available location of the aircraft for placing the ULD;

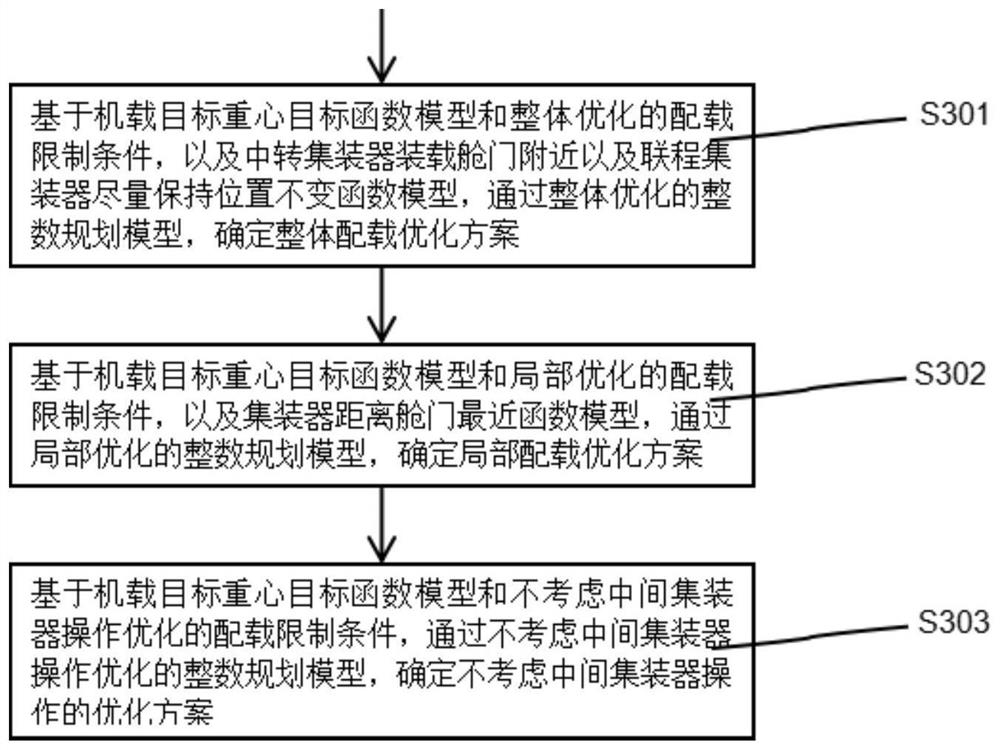

[0644] S4: With the goal of minimizing the sum of the center of gravity deviations of the two flight segments and loading the non-stop ULD near the hatch door as much as possible, and keeping the position of the interline ULD as unchanged as possible, construct a multi-segment collaborative stowage integer programming model;

[0645] S5: Determine the target center of gravity CG target ;

[0646] S6: CG the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com