Parameter acquisition device, method, ion implantation method, and semiconductor process equipment

A parameter acquisition and ion beam technology, which is applied in semiconductor/solid-state device manufacturing, discharge tubes, electrical components, etc., can solve the problem of difficulty in real-time acquisition of current density, etc., so as to improve related calculation accuracy, improve efficiency and reliability, and improve monitoring. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

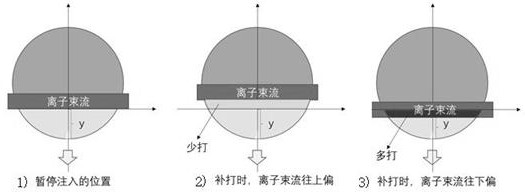

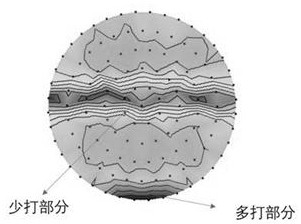

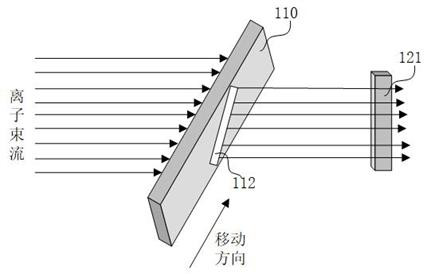

[0044] The inventors have researched semiconductor process schemes such as ion implantation, and found that when the ion beam is used for refilling of the wafer, if the position of the ion beam is readjusted, it is easy to change the relevant ion implantation parameters such as the ion position implanted into the wafer. It is also necessary to measure the process parameters such as the height of the ion beam, otherwise there may be problems such as figure 1 For the phenomenon shown, when the ion beam is deflected upward, some implant doses will be too low, resulting in the problem of undershooting in the corresponding area. When the ion beam is deflected downward, some implant doses will be too much, causing the corresponding area Multiple hits. like figure 2 As shown in the figure, the sheet resistance method can clearly characterize that in the corresponding wafer, there are problems such as unevenness in the over-dosing portion corresponding to the excessively large impla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com