Magnet-supported vertical contact separation mode nanogenerator

A nanogenerator and contact separation technology, applied in induction generators, friction generators, etc., can solve the problems of low elastic structure stability, structural wear, fatigue failure, etc., and achieve the speed of separation movement and improve stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

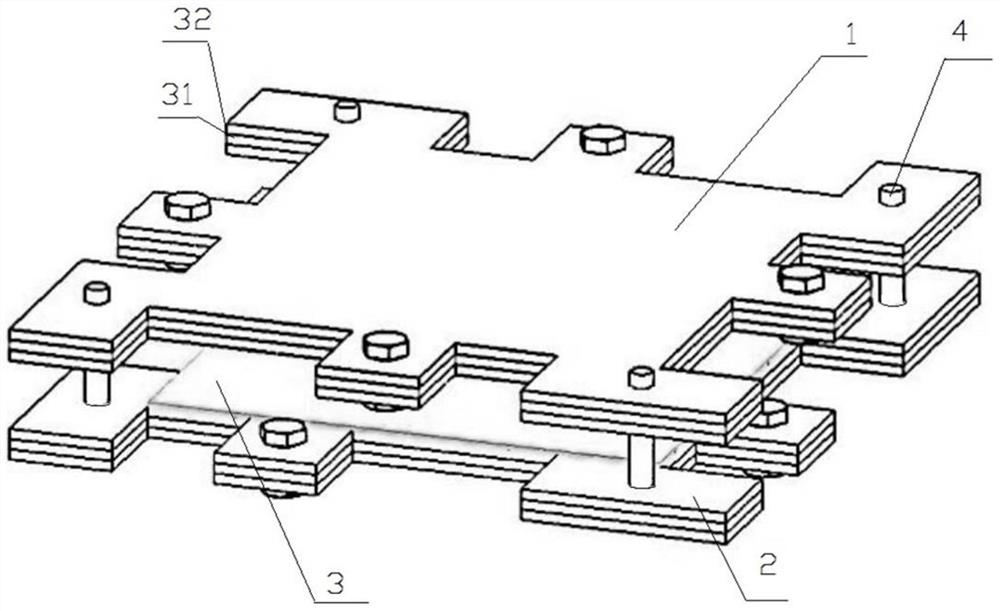

[0038] The magnet-supported vertical contact-separation mode nanogenerator includes a moving plate unit 1 and a fixed plate unit 2 stacked according to a set distance, and both the fixed plate unit and the moving plate unit include a pole plate, a The magnet and the metal electrode layer laid on the pole plate; wherein, the metal electrode layer of the moving plate unit is electrode one, and the metal electrode layer of the fixed plate unit is electrode two; electrode one and electrode two form the output electrode of the generator; An electret dielectric layer or a friction layer is laid on the first metal electrode layer; wherein, the first metal electrode layer is laid on the opposite surface of the fixed plate unit and the moving plate unit; the magnet of the fixed plate unit and the The magnets of the movable plate unit are arranged to repel each other to generate a repulsive force for separating the vertically contacted fixed plate unit from the movable plate unit, so tha...

Embodiment 2

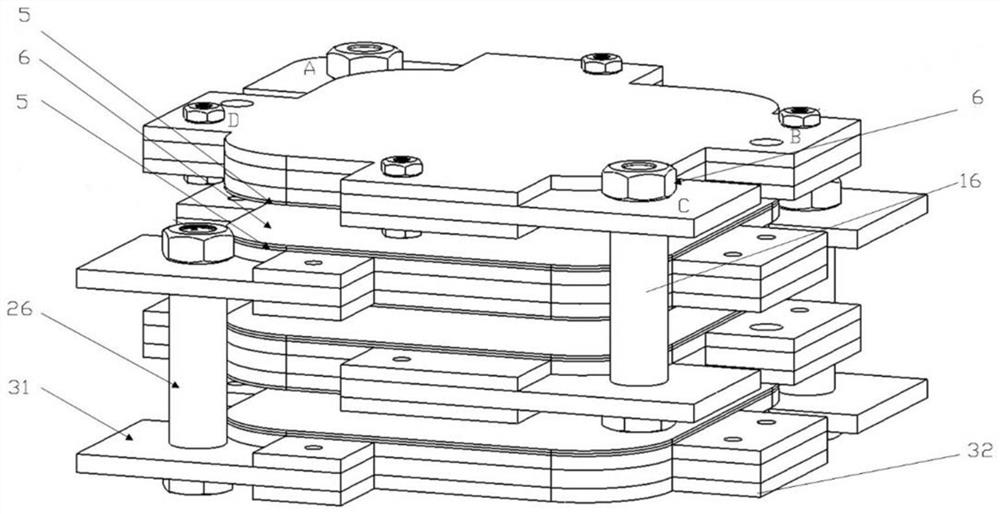

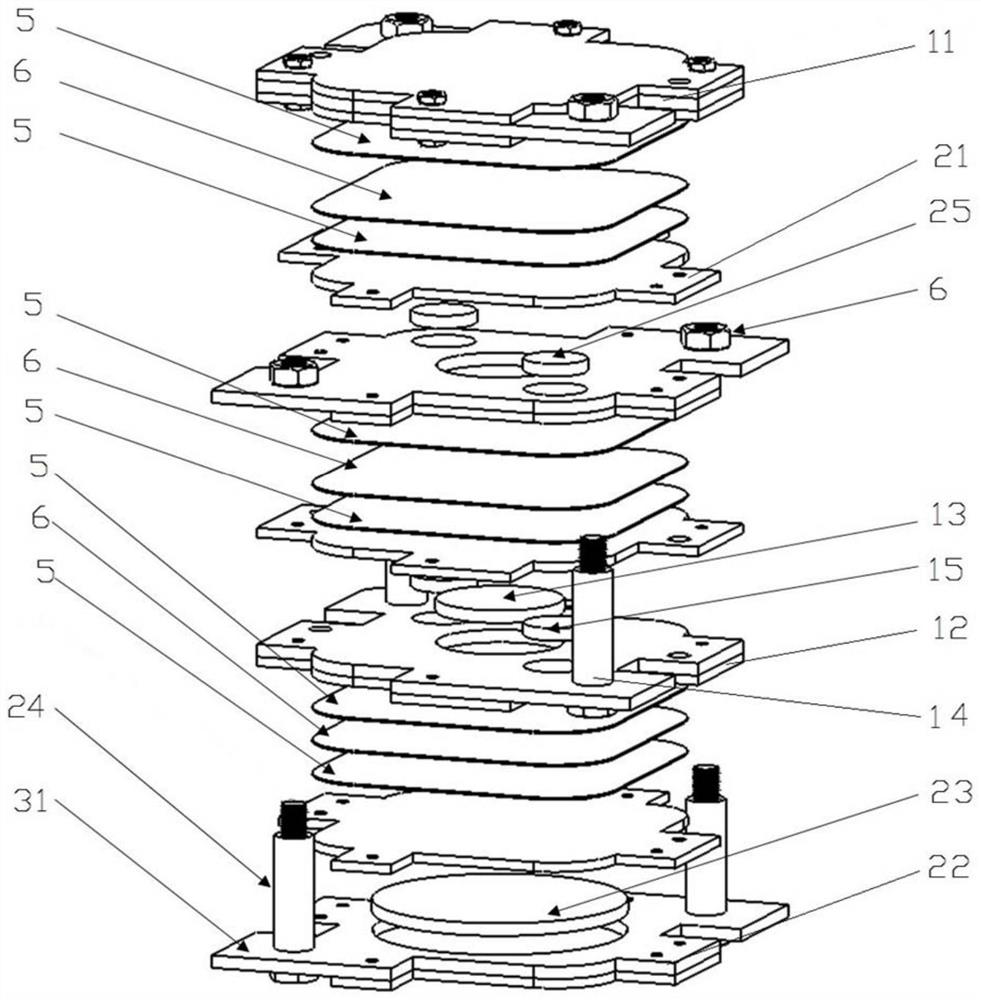

[0048] Figure 2 ~ Figure 4 The overall structure of the magnet-supported vertical contact-separation mode nanogenerator provided by Example 2 of the present invention is described. in, figure 2 Schematic diagram of the structure of the magnet-supported vertical contact-separation mode nanogenerator provided in Example 2 of the present invention, image 3 An exploded view of the structure of the magnet-supported vertical contact-separation mode nanogenerator provided in Example 2 of the present invention; Figure 4 A side view of the structure of the magnet-supported vertical contact-separation mode nanogenerator provided in Example 2 of the present invention.

[0049] refer to Figure 2 ~ Figure 4 As shown, the number of pole plates of the fixed pole plate unit 1 and the movable pole plate unit 2 is 2 respectively; the movable pole plate unit 1 includes a relatively fixed pole plate 11 and a pole plate 3 12 according to a set distance; the fixed pole plate The unit 2 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com