Single-blade wheel

A single-blade and impeller technology, applied in the direction of liquid fuel engines, machines/engines, mechanical equipment, etc., can solve the problems of expensive manufacturing, achieve the effects of reducing vibration characteristics, improving efficiency and operating reliability, and reducing noise emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

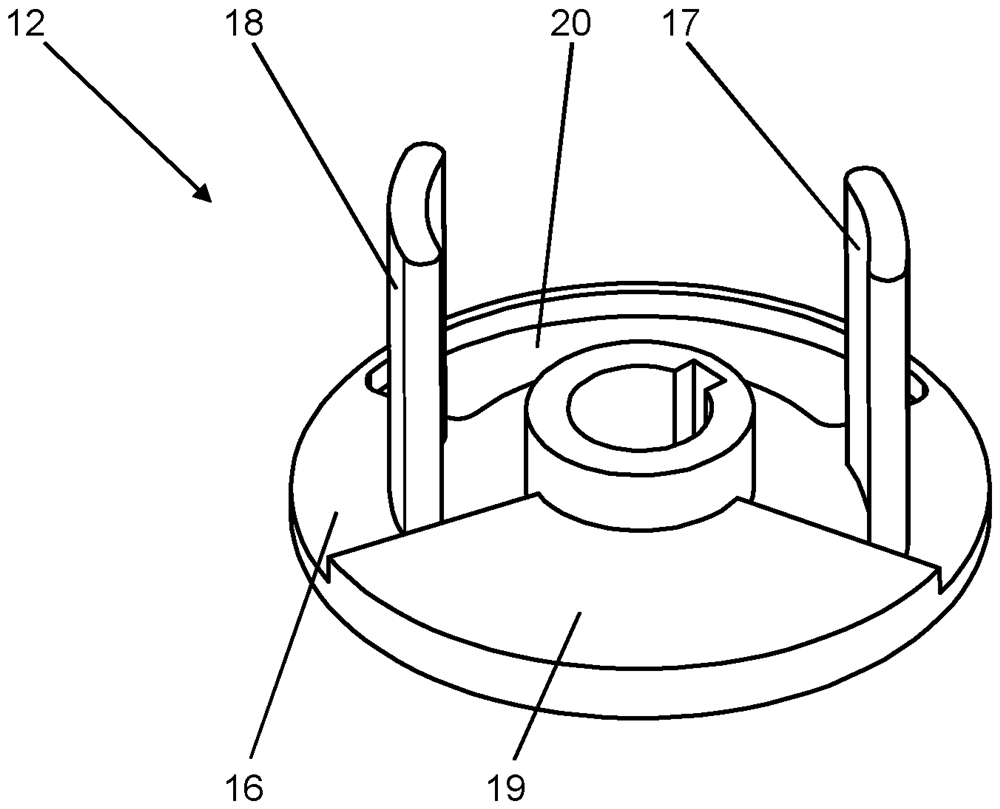

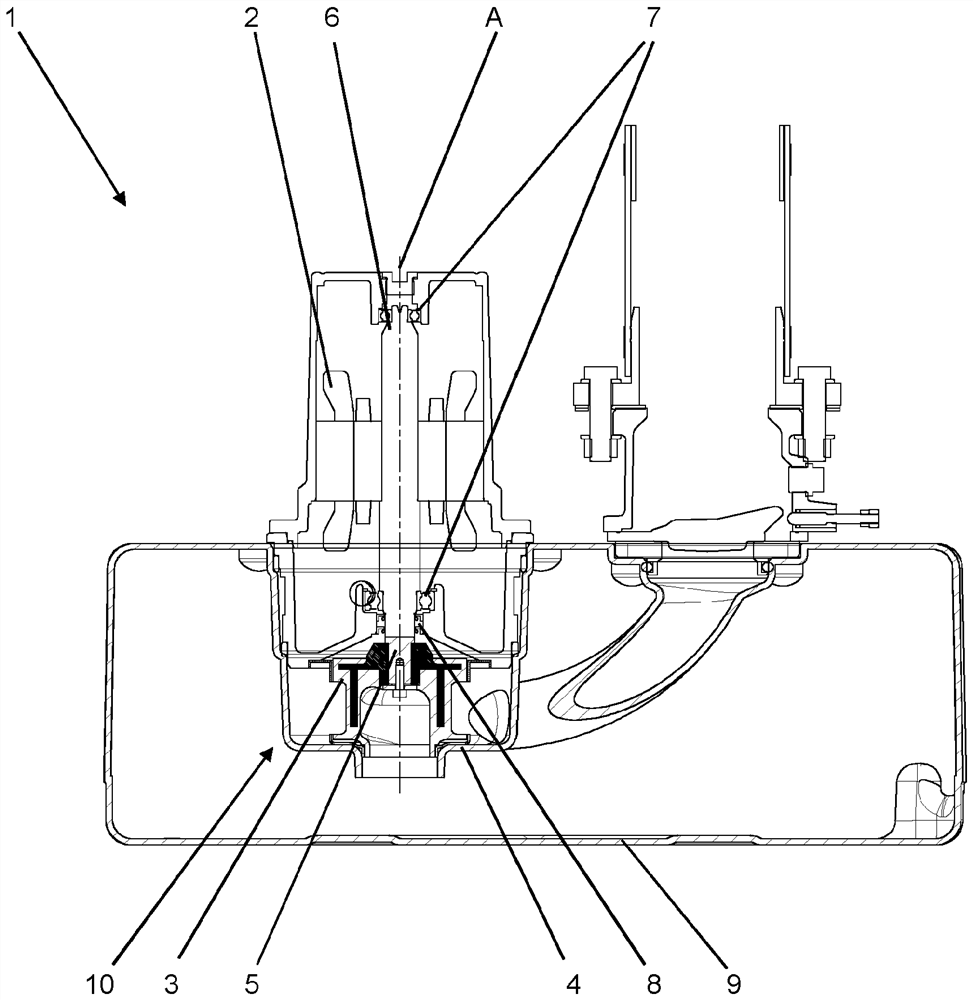

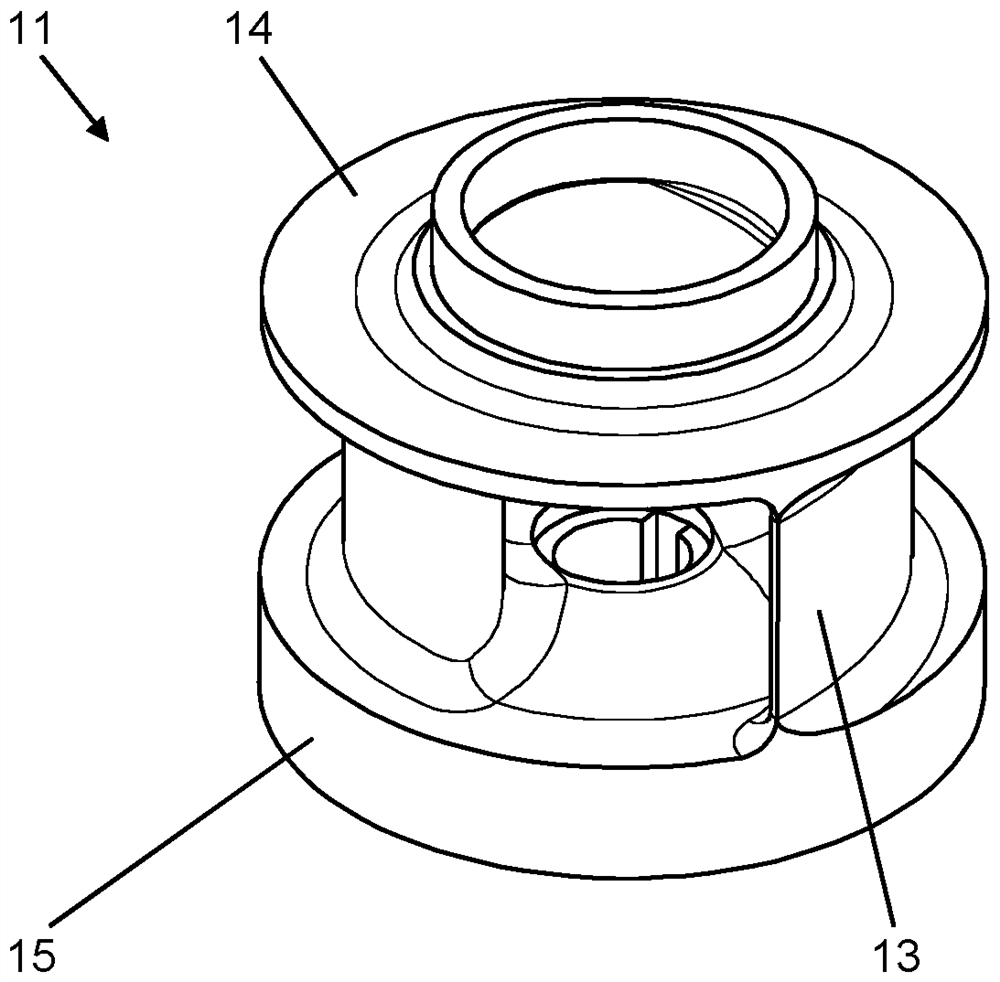

[0021] figure 1 A pump arrangement is shown having a pump 1 with a drive motor 2 and a single-blade wheel 3 , wherein the single-blade wheel 3 is arranged inside a pump housing 4 . The single-blade wheel 3 is fastened to the motor shaft 6 of the drive motor 2 via the impeller shaft 5 , which rotates about the axis A of rotation. In the illustration shown, the impeller shaft 5 and the motor shaft 6 are formed in one piece. As an alternative, the impeller shaft 5 and the motor shaft 6 can be connected to each other by a joint element.

[0022] A threaded connection is provided as a means of fixing the single-blade wheel 3 on the impeller shaft 5 , and the torque transmission takes place via rib keys. In addition, the motor shaft 6 is mounted via a rolling bearing 7 and is sealed against the single-blade wheel 3 with a seal 8 . In the exemplary embodiment shown, the pump device is arranged on a container 9 which forms the pump housing 4 in a region 10 . However, the single-bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap