Corn peeling device and corn harvester

A corn and peeling roller technology, which is applied in harvesters, agricultural machinery and implements, agriculture, etc., can solve the problems of high cost, long time, and delays in user harvesting operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

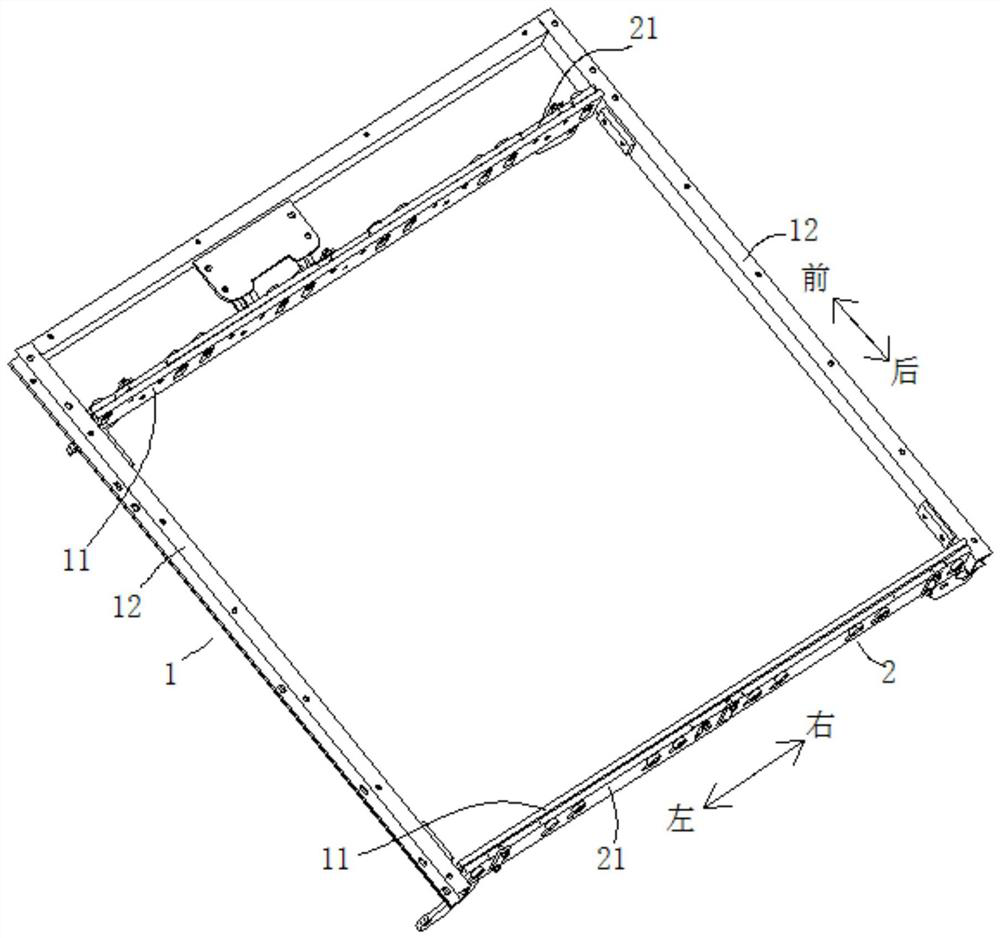

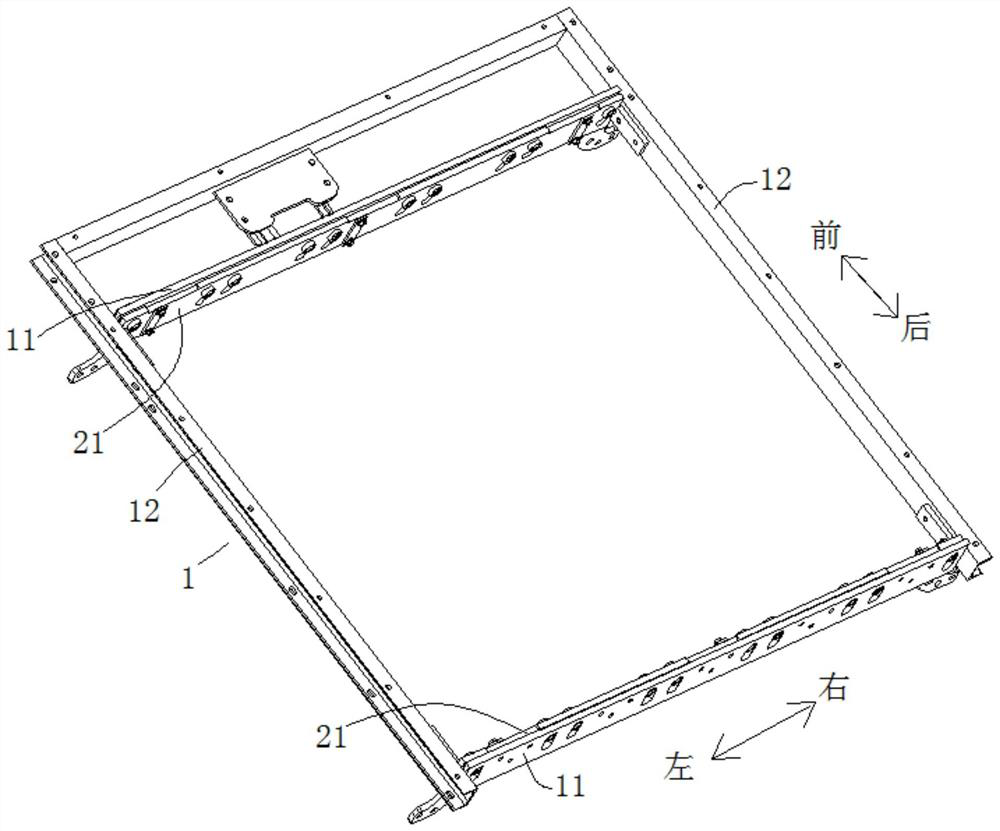

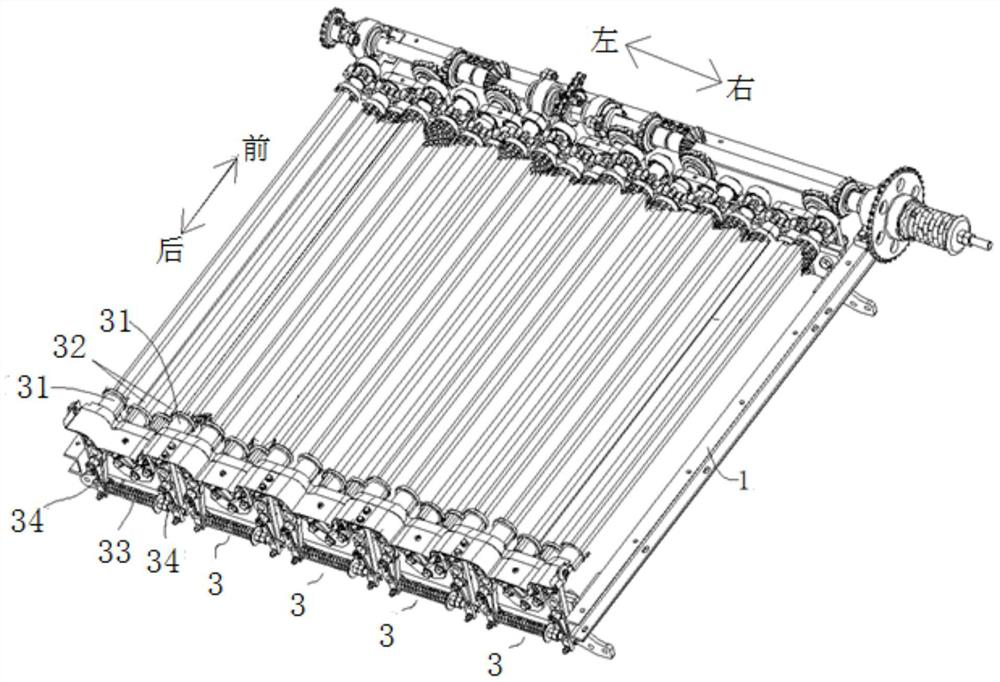

[0041] Such as figure 1 with figure 2 As shown, the present embodiment provides a corn peeling device, including a fixed roller mounting frame 1, a floating roller mounting frame 2 and multiple groups of peeling roller groups 3, and the fixed roller mounting frame 1 has two fixing plates 11, two The fixed plate 11 is arranged horizontally along the left-right direction, and is distributed at intervals along the front-rear direction. The fixed plates 11 are in one-to-one correspondence, each of the floating plates 21 is close to the corresponding fixed plate 11, multiple groups of the peeling roller groups 3 are distributed along the left and right directions, and each group of the peeling roller groups 3 includes The floating peeling roller 31 and the fixed peeling roller 32 arranged horizontally, the two ends of each of the floating peeling rollers 31 are connected with the two floating plates 21, and the two ends of each of the fixed peeling rollers 32 are connected with t...

Embodiment 2

[0056] This embodiment provides a corn harvester, including the corn peeling assembly described in Embodiment 1, so that the height of the floating peeling roller of the corn harvester can be adjusted conveniently, especially suitable for cross-regional operations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com