Hollow fiber membrane yarn structure, composite filter element assembly and water purifying device

A technology of composite filter elements and fiber membranes, which is applied in the field of composite filter elements, water purification devices, and hollow fiber membrane structures. It can solve the problems of short life, easy breakage of hollow fiber membranes, etc. , Improve the effect of compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

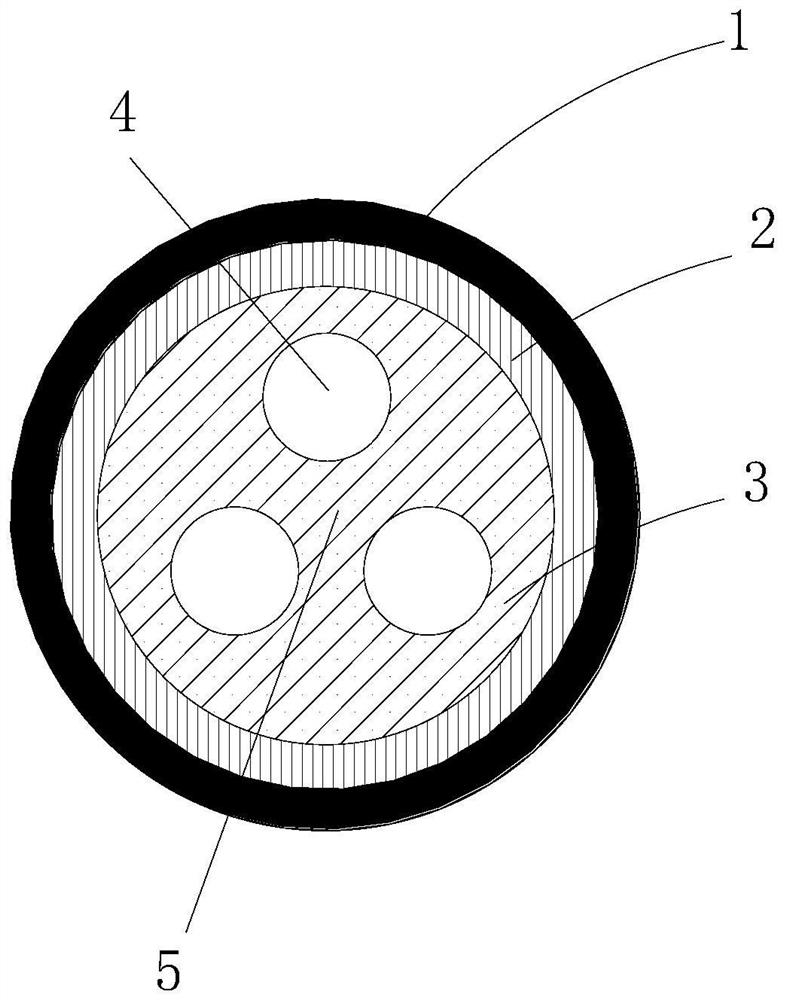

[0031] Example 1, in some implementations, the cross-sectional shape of the hollow cavity 4 is circular; and / or,

[0032] There are three hollow cavities 4 , and the three hollow cavities 4 are spaced apart from each other along the circumferential direction of the supporting base layer 3 , and the solid support portion 5 is located between the three hollow cavities 4 . The hollow cavity of the present invention is preferably circular, and water can pass through it. The hollow cavity of the present invention is preferably three. The three hollow cavities are distributed along the axial direction of the supporting base at intervals, and can form three channels for water supply and circulation.

[0033] Specific embodiments of the present invention are as attached figure 1 As shown, the present invention provides an integrally formed three-channel membrane filament structure of a hollow fiber membrane module, including a separation layer 1 (nanofiltration material), an intermedi...

Embodiment 2

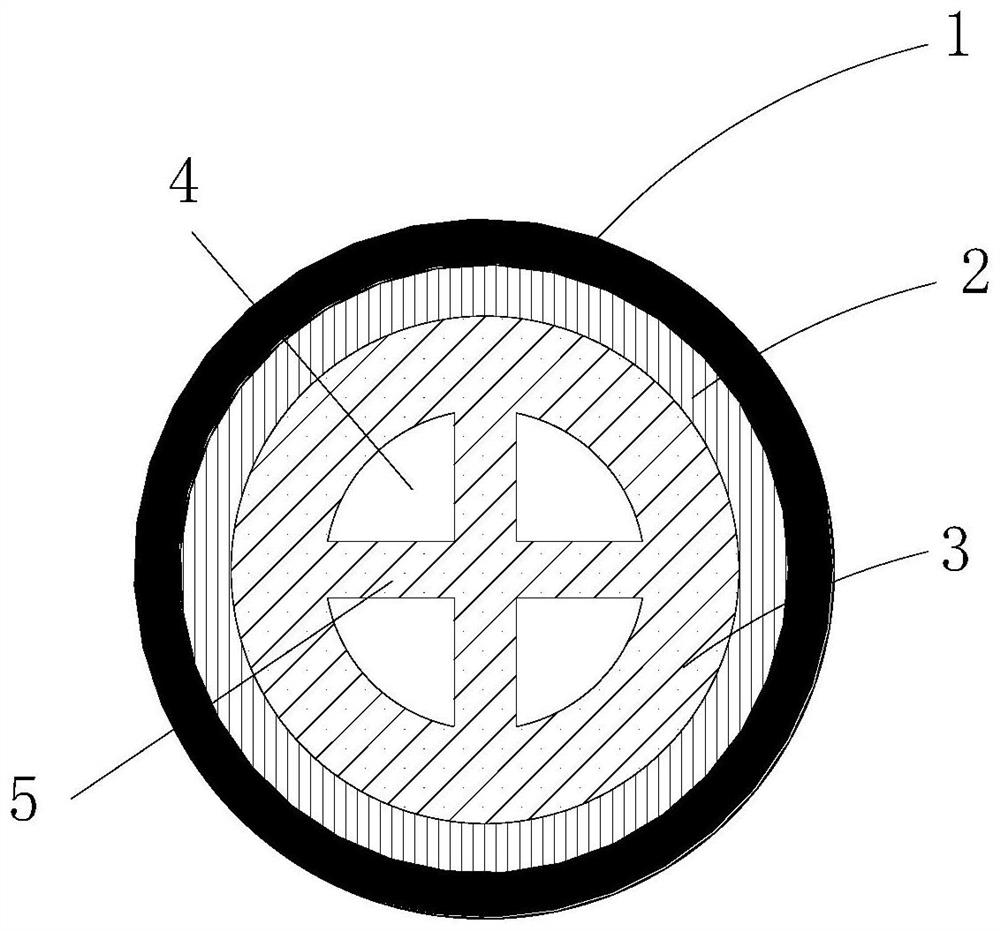

[0035] Example 2, in some implementations, in the cross section of the support base layer 3, the solid support part 5 includes two partition bars arranged in the hollow cavity 4, through the partition bars, the The hollow cavity 4 is divided into 4 sub-cavities (preferably, the size of the 4 sub-cavities is the same). Such as figure 2 As shown, in Embodiment 2 of the present invention, the hollow cavity is separated by two partition bars, thereby forming 4 sub-cavities, thereby forming 4 channels for water supply and circulation.

[0036] In some embodiments, in the cross-section of the supporting base layer 3, two partition bars are vertically intersected; the four sub-cavities are fan-shaped structures with a central angle of 90°. This is the preferred structural form of the four sub-cavities of the present invention, and the preferred arrangement form of the partition bar.

[0037] Specific embodiment of the present invention 2 is attached figure 2 As shown, the presen...

Embodiment 3

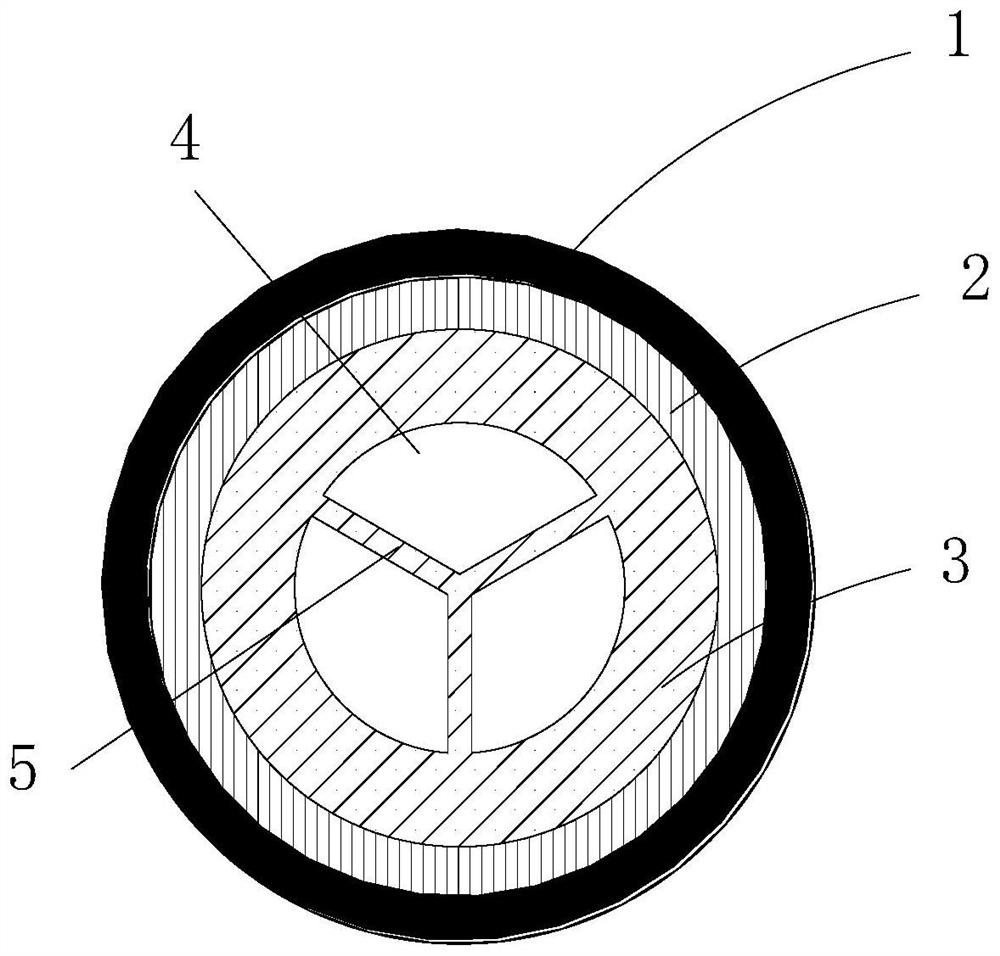

[0038]Example 3, in some implementations, in the cross section of the supporting base layer 3, the solid support part 5 includes three partition bars arranged in the hollow cavity 4, through the partition bars, the The hollow cavity 4 is divided into three sub-cavities (the three sub-cavities are preferably of the same size). like image 3 As mentioned above, in Embodiment 3 of the present invention, the hollow cavity is divided by three partition bars, thereby forming three sub-cavities, thereby forming three channels for water supply and circulation.

[0039] In some embodiments, in the cross-section of the supporting base layer 3, one end of each of the three spacers is connected to the center of the separation layer 1, and the other ends of each extend outward in the radial direction, and are connected to each other. The two partition bars are rotated by 120° in the circumferential direction; and / or,

[0040] In the cross-section of the support base layer 3, the three pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com