Power control method for laser repeated combination track

A technology of repeated combination and power control, which is applied in laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve problems such as difficult and precise control of power output density, and achieve the effect of solving power control problems and realizing power output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

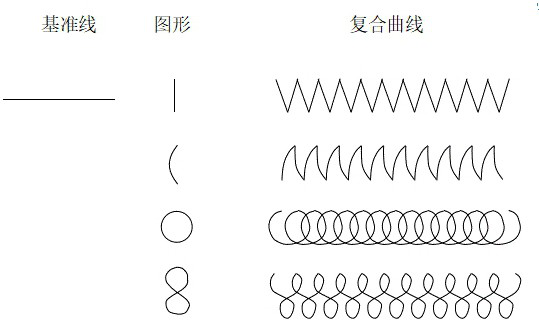

Method used

Image

Examples

Embodiment

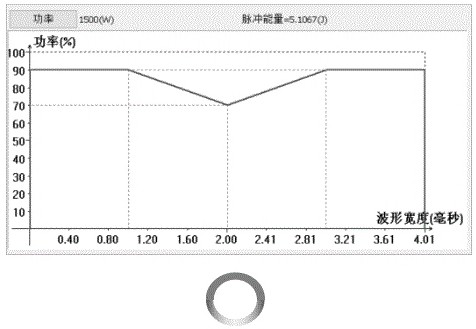

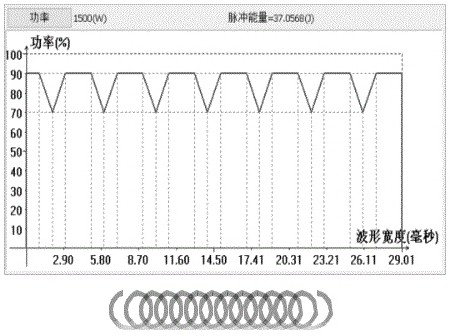

[0060] Refer to attached Figure 8 As shown, set a weld reference line to be 50mm long, the jitter width to be 2mm, and the overlapping distance to be 1mm, then the software will generate 49 spiral patterns. Modify the power curve of one of the spiral patterns, and then automatically apply it to the remaining 48 patterns to achieve a power output curve that changes periodically according to the total length of the spiral.

[0061] When it is necessary to adjust the power curve of the entire curve, it only needs to be modified once. There is no need to sequentially modify the power settings corresponding to the 49 spiral patterns.

[0062] A computer-readable storage medium, where a computer program is stored on the computer-readable storage medium, and when the computer program is executed by a processor, the steps of a power control method for laser repetitively combined tracks described in the present invention are implemented.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com