Prefabricated box culvert process and assembling method

A box culvert and process technology, applied in the direction of manufacturing tools, molds, ceramic molding cores, etc., can solve the problems of complex process, inconvenient engineering construction, and long construction period of cast-in-place box culverts, so as to facilitate seamless connection and reduce insufficient filling The possibility of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following is attached figure 1 The application is described in further detail.

[0044] The embodiment of the application discloses a process and assembly method of a prefabricated box culvert.

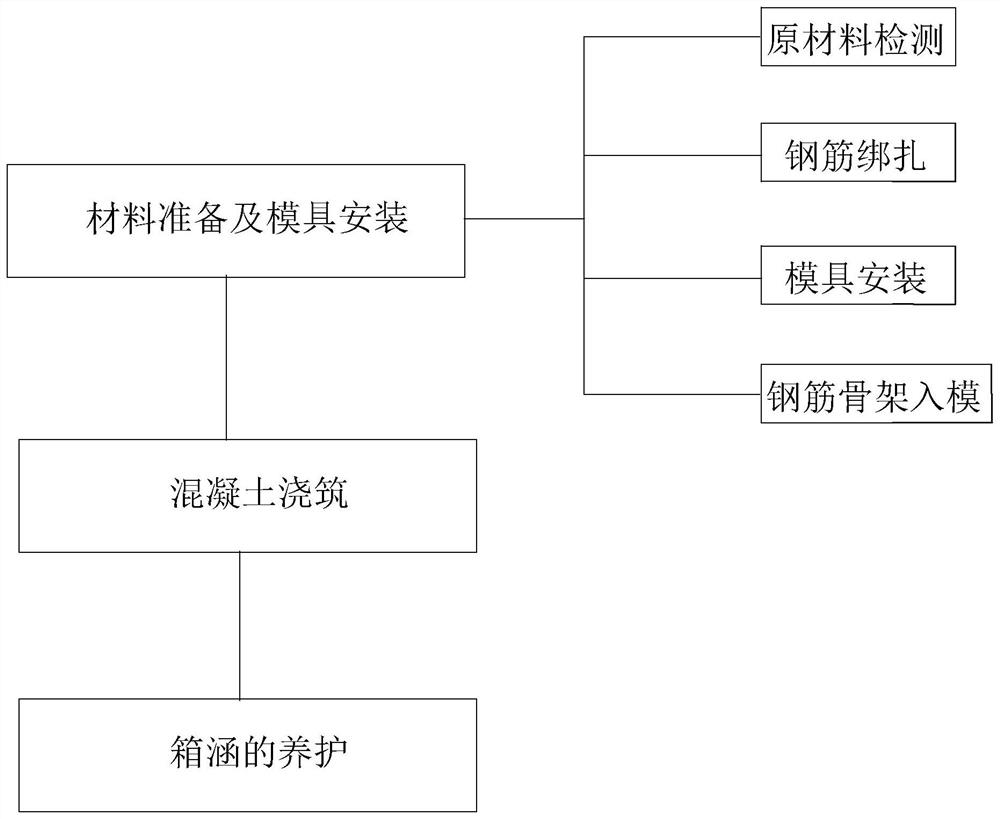

[0045] refer to figure 1 , the first aspect, a prefabricated box culvert process, including the following production process:

[0046] Material preparation and mold installation:

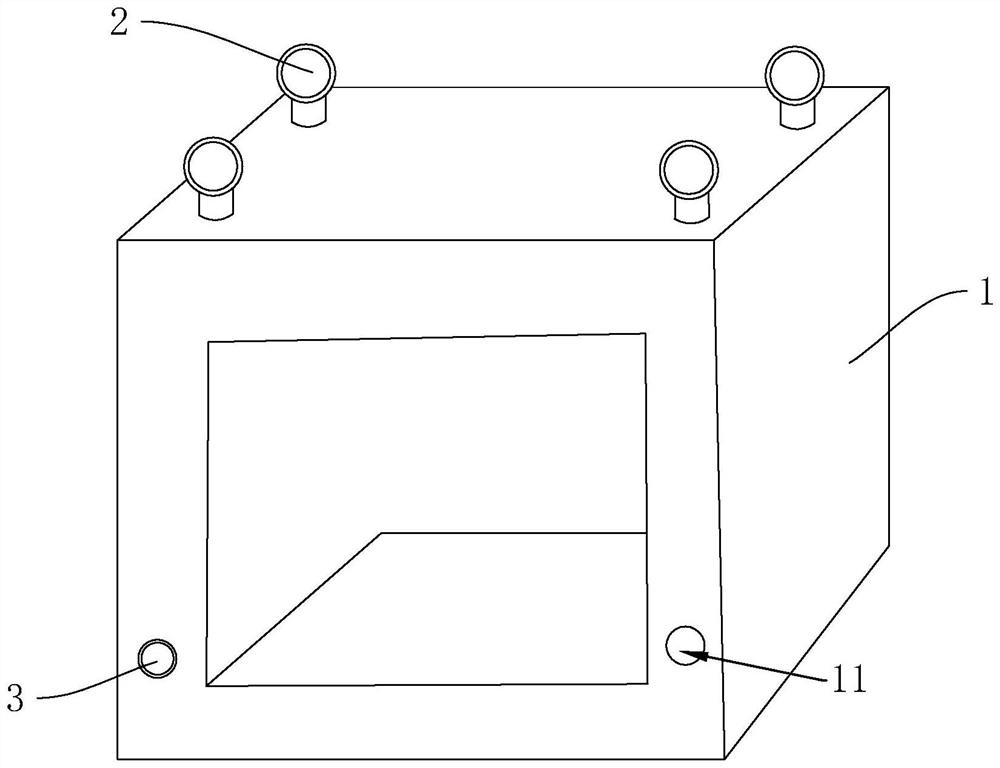

[0047] (1) Raw material testing: Sampling and testing the steel bars and cement in batches to determine the quality of the steel bars and cement, thereby improving the quality of the prefabricated box culvert 1;

[0048] (2) Steel bar binding: When binding steel bars in different directions, cross-bound horizontal steel bars and vertical steel bars to form a steel bar skeleton by dismantling the processing method, and ensure that the horizontal steel bars and vertical steel bars are always in a vertical state during the binding process. The reinforced skeleton is convenient to improve the str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com