Multifunctional assembly type elevator pit structure

An elevator pit and assembly technology, which is used in transportation and packaging, lifting equipment in mines, elevators, etc., can solve the problems of troublesome installation of the overall structure, oxidation and corrosion of shock absorption devices, inconvenient disassembly and maintenance, etc. Risk of water corrosion, quick installation and removal for repairs, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

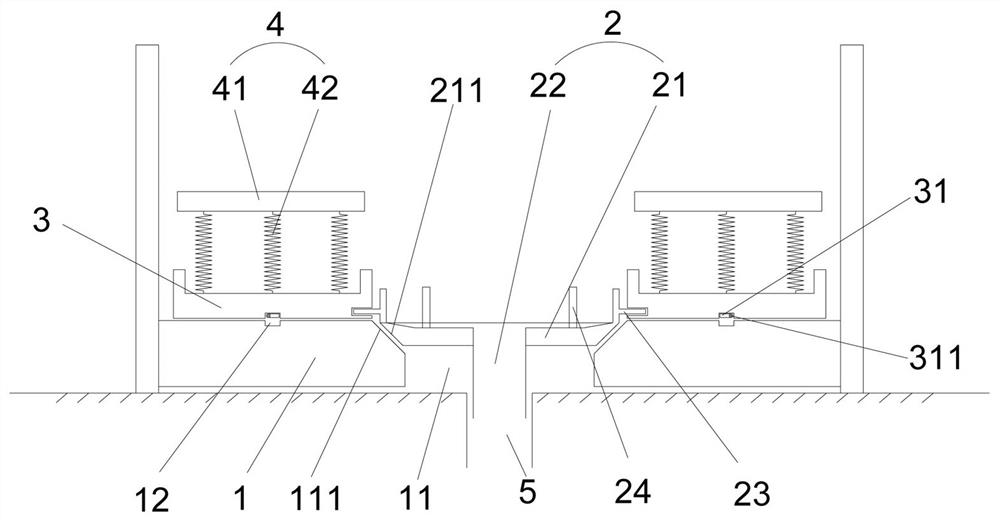

[0029] Example 1: such as Figure 1 、 2 As shown, only one embodiment of the present invention, a multifunctional assembly type elevator pit structure, comprising a base 1 provided in the middle of the gap 11, a sewage component disposed at the notch 11 and a function board disposed on the base 11, the bottom of the shaft is provided with a main drain pipe 5, the sewer member 2 comprises a water tray 21 and disposed in the middle of the water guide tray 21 down to the main drain pipe 5 in communication with the sewer pipe 22, the function board 3 is provided with a rotating block 31 on the lower side, The base 1 on the upper side is provided with a first card slot for facilitating the insertion of the rotating block 31 12, the function board 3 is provided with a second card slot 32 near the side of the notch 11, the water guide tray 21 edge is provided for inserting into the second card slot 32, such that when the card block 23 is inserted into the second card slot 32, the control...

Embodiment 2

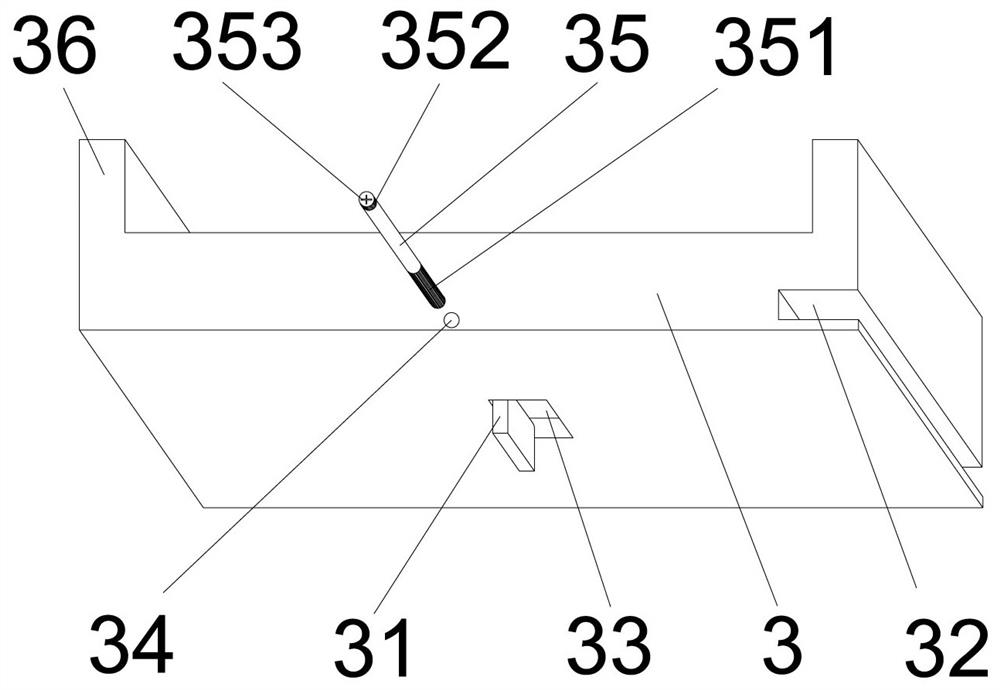

[0038] Example two, still as Figure 1 、 2 As shown, only one embodiment of the present invention, on the basis of Example I, the present invention is a multifunctional assembly type elevator pit structure, the rotating block 31 is generally rotated using motor control, but in the case of complex pit pit, manual control of rotation may also be employed, at this time:

[0039] The rotary block 31 is provided with a rotating shaft hole 311, and the rotary shaft hole 311 is disposed on the side of the retracting groove 33 away from the second card slot 32, the function board 3 side wall is provided with an insertion hole 34 for communicating with the retractable slot 33, and the insertion hole 34 is provided with a coaxial setting with the rotary shaft hole 311, the insertion hole 34 is provided with a rotating column 35 for insertion into the rotating shaft hole 311. Then the rotation block 31 may be controlled by rotating the end of the insertion hole 35 leaking out of the insertio...

Embodiment 3

[0044] Example THREE, still as Figure 1 、 2 As shown, only one embodiment of the present invention, on the basis of Example I, the present invention is a multifunctional assembly type elevator pit structure, the upper side of the notch 11 inner wall is provided with a first inclined surface 111, the outer side of the water guide plate 21 is provided with a second inclined surface 211 for the first inclined surface 111 in conjunction with the second tilt surface 211, the installation stability of the sewer part 2 is better, can also make the sewer part 2 better fit the inner side wall of the gap 11, the water drainage capacity is better.

[0045] Further, the upper side of the water guide plate 21 is provided with a filter baffle 24 wound around the outside of the sewer pipe 22, effectively blocking the debris in the accumulated water on the outside of the filter baffle 24, to avoid the sewer pipe 22 to block.

[0046] Further, the edge of the function board 3 is provided with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com