Planetary roller screw life test bench form and position error self-adaptive device

A life test, planetary roller technology, applied in the direction of measuring device, testing of mechanical components, testing of machine/structural components, etc., can solve the problem that the accuracy of the test bench cannot meet the requirements, and the accuracy of the test bench cannot be determined.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

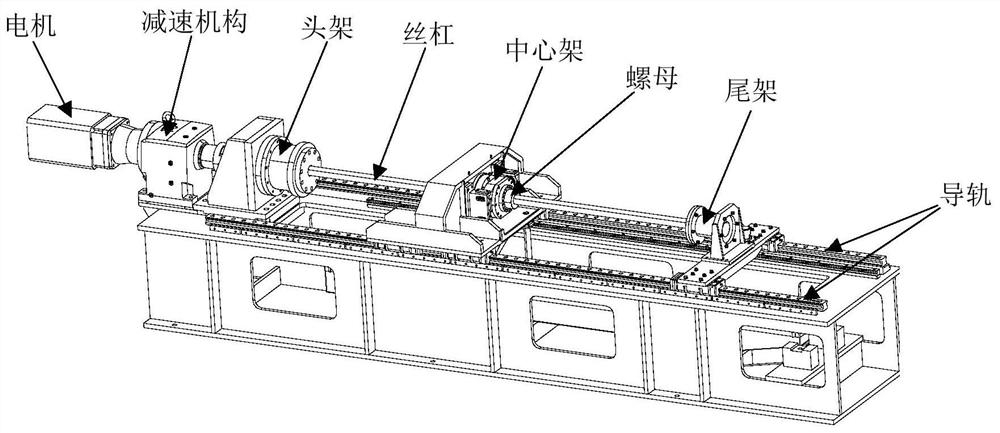

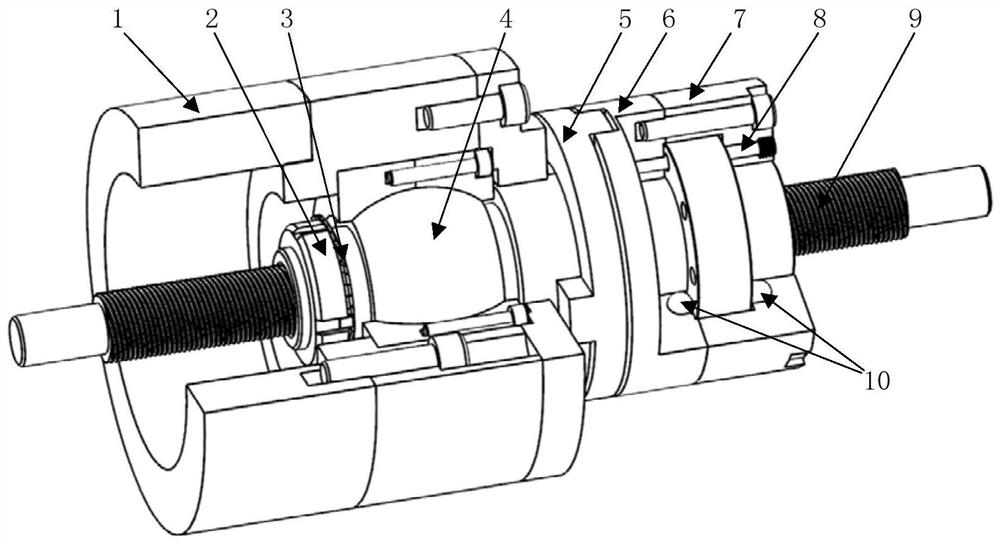

[0032] Such as figure 2 As shown, the shape and position error adaptive device of the planetary roller screw life test bench of the present invention is used to adaptively compensate the planetary roller screw 9 (see Figure 8 ) During the life test, due to the fact that the shape and position tolerance of the test bench cannot meet the requirements, and the lead screw is deformed due to the large length-to-diameter ratio and large load, the axis of the inner hole of the center frame and the axis of each point of the lead screw exist in each degree of freedom. error.

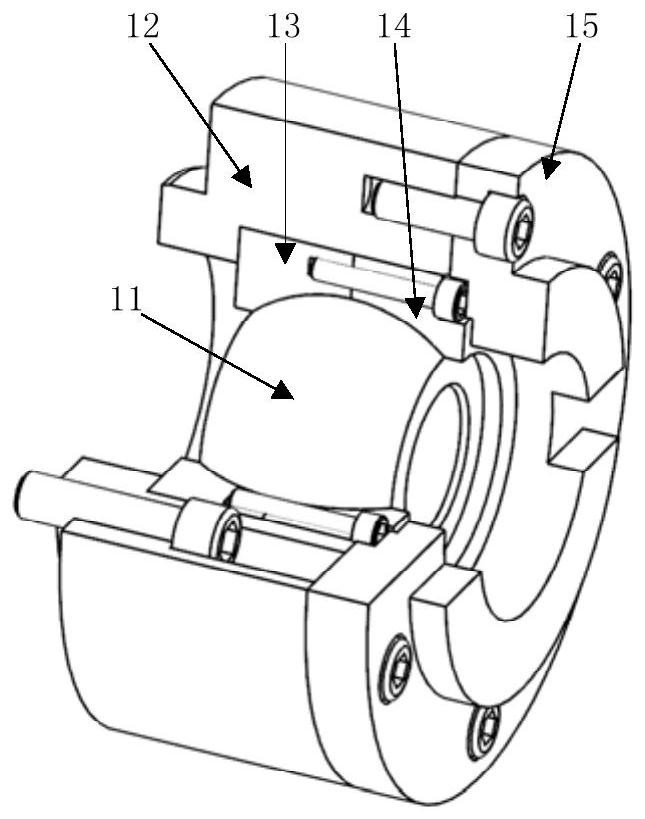

[0033] The device is mainly composed of center frame 1, lock nut 2, stop washer 3, ball hinge assembly 4, cross slider 5, left nut cover 6, right nut cover 7, pin 8, steel ball 10 and other parts of the life test bench Composition, the ball joint assembly 4 is fixedly connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com