Rapid sample conveying system and method for extremely low temperature environment

An extremely low-temperature, fast technology, applied in the field of machinery, can solve problems such as inconvenience, achieve the effect of saving the space on the top of the equipment and expanding the compatibility of the installation environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

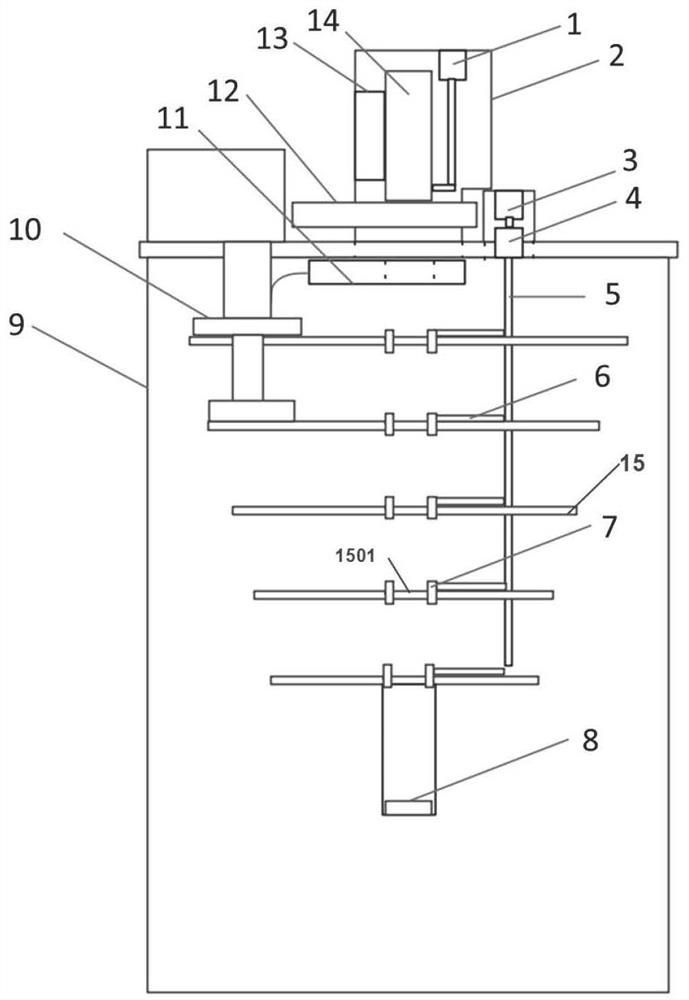

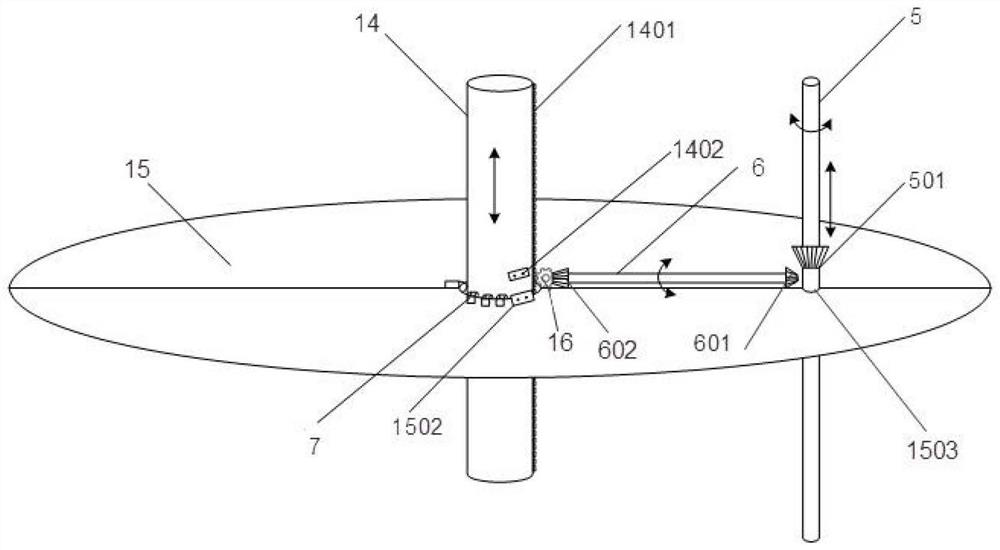

[0030] In the field of cryogenic equipment or systems, extremely low temperature refers to equipment or systems that can provide a temperature range below 1K. The present invention discloses a rapid sample delivery system for extremely low temperature environments, specifically as figure 1As shown, the system includes: a first stepping motor 1, a second stepping motor 4, a vertical transmission rod 5, a cold plate transmission rod 6, a sample tube 14, a cold plate 15 and a transmission gear 16; the first stepping motor 1 drives the sample tube 14 to move in the vertical direction; the first stepper motor 1 controls the range of movement of the sample tube 14 from above the first cold plate to the range of the transition chamber, and one end of the vertical transmission rod 5 is connected to the second The stepper motor 4 is connected, and the other end is connected with the cold plate drive rod 6; the cold plate drive rod 6 is horizontally arranged on the cold plate 15, and is ...

Embodiment 2

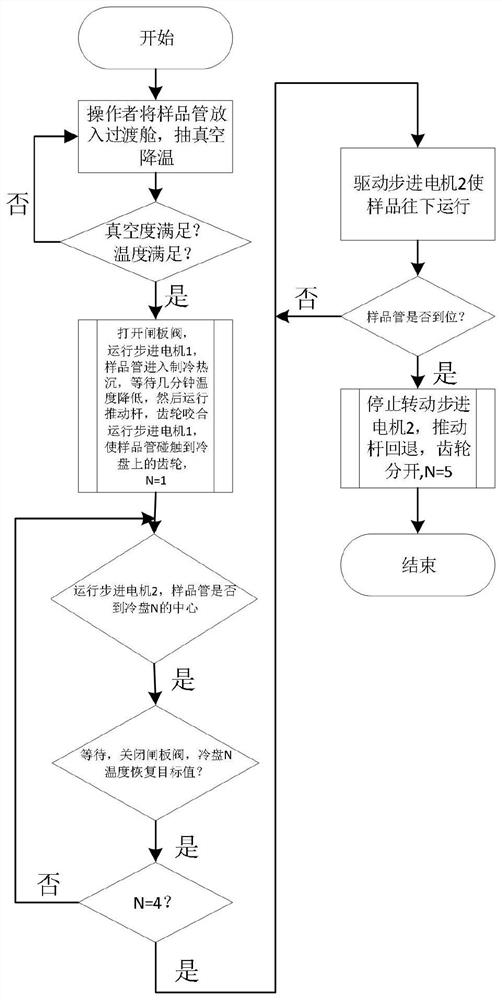

[0051] According to a kind of fast sample delivery system for extremely low temperature environment described in embodiment 1, a kind of fast sample delivery method for very low temperature environment is correspondingly provided, such as figure 2 A schematic diagram of sample tube transmission for a rapid sample transfer system used in an extremely low temperature environment, and the corresponding specific methods include:

[0052] Run the first stepper motor, send the sample tube to the cold plate, run the second stepper motor, and the second stepper motor drives the rotation of the vertical transmission rod, and makes the sample on the sample tube The tube transmission gear meshes with the transmission gear; the vertical transmission rod drives the cold plate transmission rod to rotate, the cold plate transmission rod drives the transmission gear to rotate, and the electric push rod drives the cold plate transmission rod to move, so that the The cold plate drive rod is me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com