Multifunctional electric mini-tiller

A micro-tiller, multi-functional technology, applied in the direction of agricultural machinery and implements, agriculture, shovel, etc., can solve the problems of soil scraper damage, replacement, high maintenance frequency, and the height of the roller cannot be adjusted adaptively

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The following is attached Figure 1-6 The application is described in further detail.

[0054] The embodiment of the present application discloses a multifunctional electric tiller.

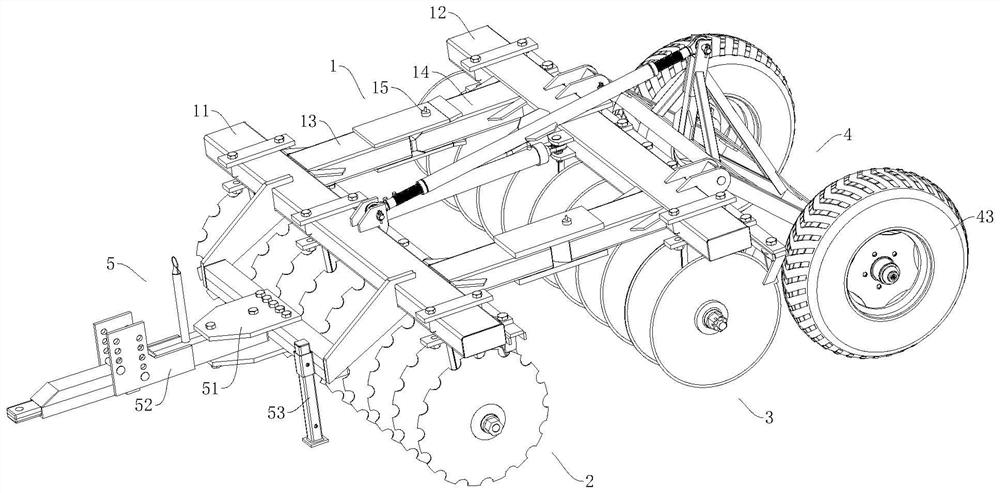

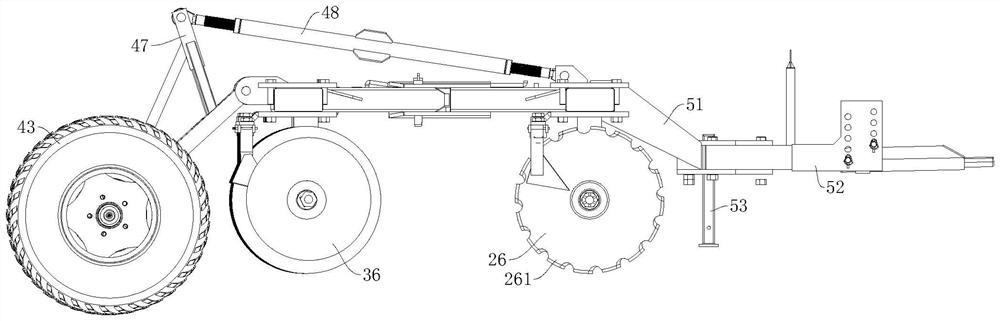

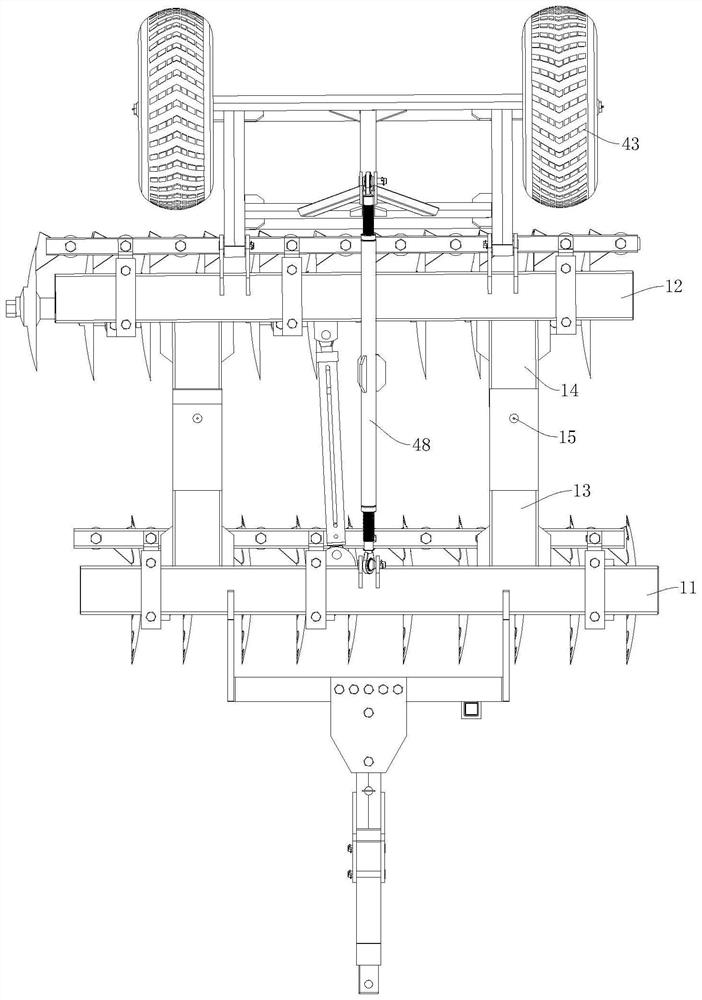

[0055] refer to figure 1 , figure 2 , image 3 A multifunctional electric tiller, comprising a mounting frame assembly 1, a front disc harrow assembly 2 arranged on the mounting frame assembly 1, a rear disc harrow assembly 3 and a roller support assembly 4, the front disc harrow assembly 2 is connected with The traction assembly 5, wherein the front disc harrow assembly 2 and the rear disc harrow assembly 3 are axially staggered.

[0056] The traction assembly 5 is mainly used to connect the external traction equipment. The traction equipment provides traction power for the whole tiller. The roller support assembly 4 mainly plays the role of moving support for the mounting frame assembly 1. The front disc harrow assembly 2 and the rear disc harrow assembly 2 The disc harrow assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com