Automatic ultrasonic welding equipment for radar support of automobile bumper

An automobile bumper, ultrasonic welding technology, applied in welding equipment, welding equipment, auxiliary welding equipment and other directions, can solve the problems of low welding efficiency of radar brackets, and the welding quality cannot be well guaranteed, so as to meet the needs of flexible production, The effect of high positioning accuracy and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

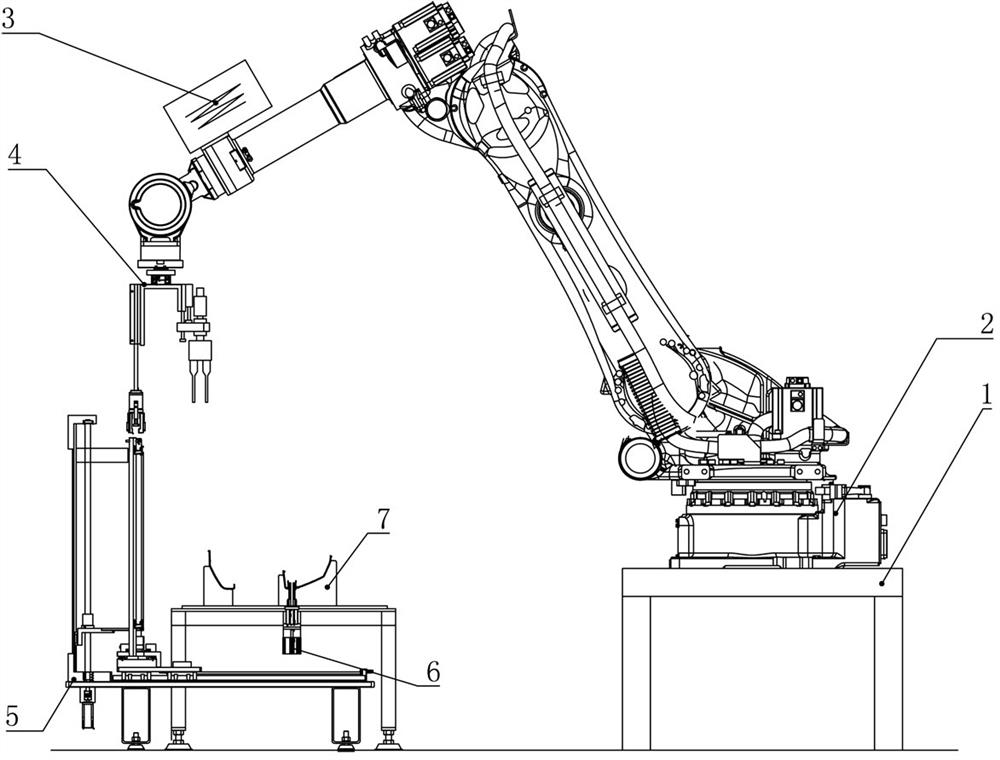

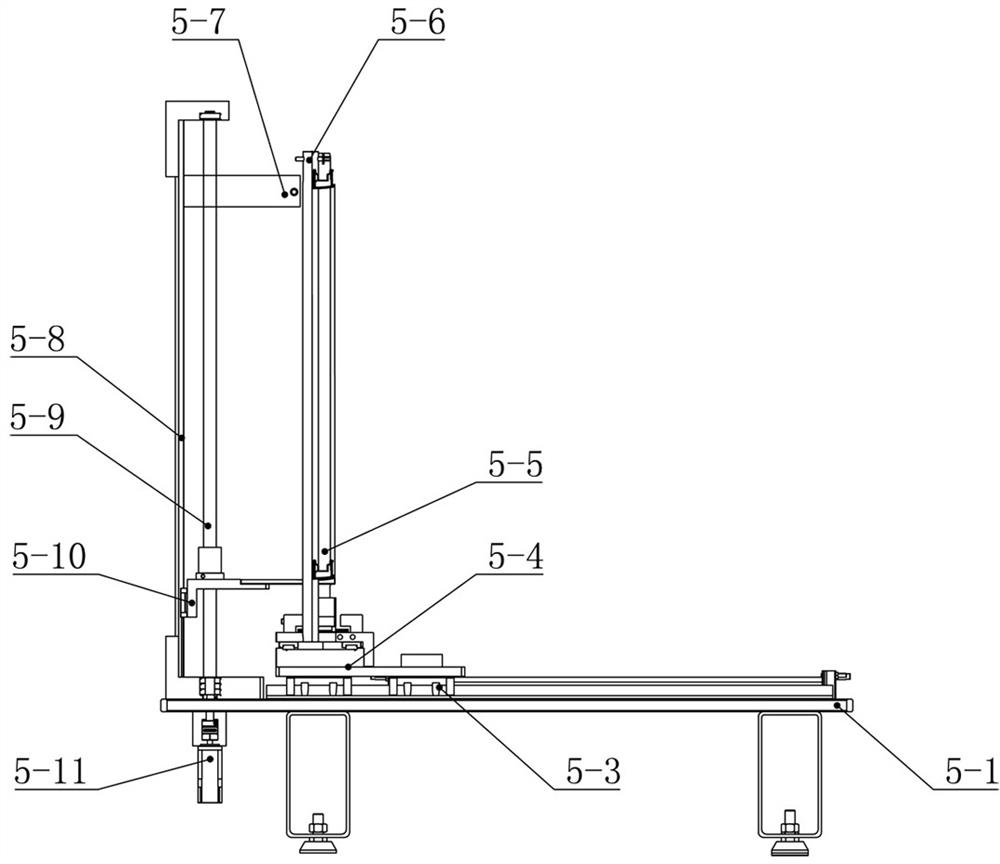

[0019] Such as Figure 1 to Figure 5 The ultrasonic automatic welding equipment for the radar bracket of the automobile bumper shown includes an ultrasonic generator 3, an ultrasonic welding device 4-8 and a welding fixture 5, and also includes a robot. The robot here is a six-axis robot 2, and the six-axis robot is set on the bracket On the platform, the ultrasonic generator 3 is arranged on the six-axis robot.

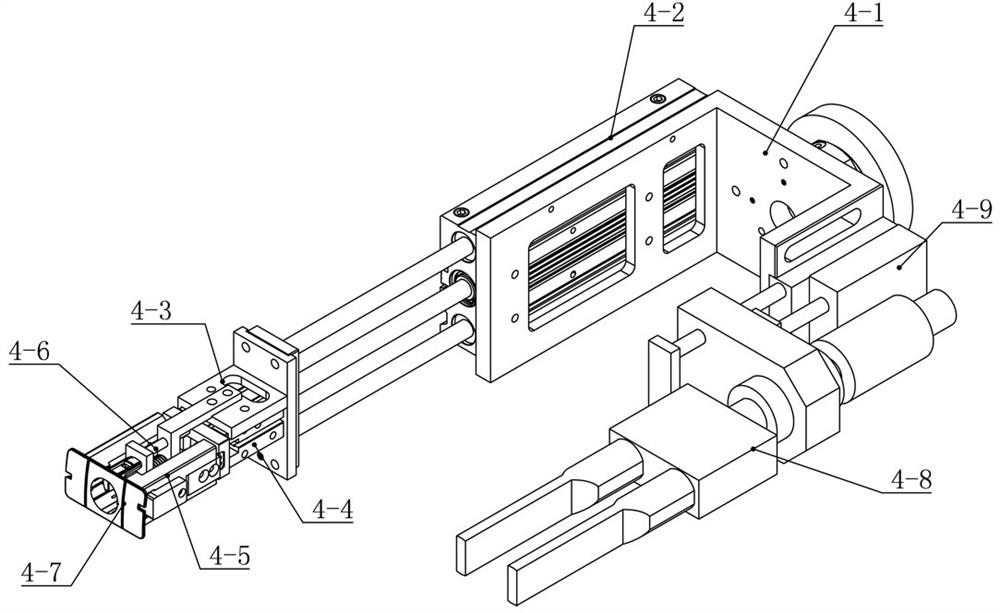

[0020] The working end of the six-axis robot 2 is equipped with a radar bracket clamping device 4 for clamping and correcting the radar bracket. The radar bracket clamping device includes a U-shaped support 4-1 installed on the working end of the six-axis robot. The U-shaped side of the seat 4-1 is provided with an ultrasonic welding device 4-8 through a depth cylinder 4-9 for testing the depth of the radar support position, and the U-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com